Contact us

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

TekExpress 400G-TXE Electrical Compliance Solution for Real Time Oscilloscope Application Help

This document provides the operation instructions for the TekExpress 400G-TXE Electrical Compliance Solution Software Application, for DPO/DPS/MSO70000 SX and DX Series Oscilloscopes.

This manual applies to:

DPO77002SX, DPS77004SX, DPO75902SX, DPS75904SX, DPO75002SX, DPS75004SX, DPO73304SX, DPS73308SX, DPO73304DX, MSO73304DX

By downloading, you agree to the terms and conditions of the Manuals Download Agreement.

Manuals Download Agreement

ATTENTION: please read the following terms and conditions carefully before downloading any documents from this website. By downloading manuals from Tektronix' website, you agree to the following terms and conditions:

Manuals for Products That Are Currently Supported:

Tektronix hereby grants permission and license to owners of Tektronix instruments to download and reproduce the manuals on this website for their own internal or personal use. Manuals for currently supported products may not be reproduced for distribution to others unless specifically authorized in writing by Tektronix, Inc.

A Tektronix manual may have been revised to reflect changes made to the product during its manufacturing life. Thus, different versions of a manual may exist for any given product. Care should be taken to ensure that one obtains the proper manual version for a specific product serial number.

Manuals for Products That Are No Longer Supported:

Tektronix cannot provide manuals for measurement products that are no longer eligible for long term support. Tektronix hereby grants permission and license for others to reproduce and distribute copies of any Tektronix measurement product manual, including user manuals, operator's manuals, service manuals, and the like, that (a) have a Tektronix Part Number and (b) are for a measurement product that is no longer supported by Tektronix.

A Tektronix manual may be revised to reflect changes made to the product during its manufacturing life. Thus, different versions of a manual may exist for any given product. Care should be taken to ensure that one obtains the proper manual version for a specific product serial number.

This permission and license does not apply to any manual or other publication that is still available from Tektronix, or to any manual or other publication for a video production product or a color printer product.

Disclaimer:

Tektronix does not warrant the accuracy or completeness of the information, text, graphics, schematics, parts lists, or other material contained within any measurement product manual or other publication that is not supplied by Tektronix or that is produced or distributed in accordance with the permission and license set forth above.

Tektronix may make changes to the content of this website or to its products at any time without notice.

Limitation of Liability:

TEKTRONIX SHALL NOT BE LIABLE FOR ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR FOR INFRINGEMENT OF INTELLECTUAL PROPERTY) ARISING OUT OF THE USE OF ANY MEASUREMENT PRODUCT MANUAL OR OTHER PUBLICATION PRODUCED OR DISTRIBUTED IN ACCORDANCE WITH THE PERMISSION AND LICENSE SET FORTH ABOVE.

Read Online

400G-TXE COMPLIANCE MEASUREMENTS

- DC common mode output voltage

- AC Common Mode Output Voltage

- Single-ended output voltage

- Diff peak to peak output voltage Tx enabled

- Diff peak to peak output voltage Tx disabled

- Transition time

- Eye width, VEC (Vertical Eye Closure), Eye height, Eye linearity, and Eye symmetry mask width

- Signal-to-noise and distortion ratio

- Pre-cursor and post-cursor equalization ratio

- Coefficient range (OIF)

- Coefficient range (IEEE)

- Far end pre-cursor ISI ratio

- Transmitter output residual ISI

- Normalized coefficients step size

- Coefficient initialization

- Signaling rate

- Level separation mismatch ratio (RLM)

- Linear fit pulse peak

- Steady state voltage

- Even odd jitter

- Uncorrelated bounded high probability jitter & Uncorrelated unbounded gaussian jitter

- Uncorrelated jitter RMS and uncorrelated J3 and J4 Jitter

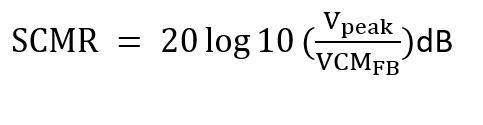

- Signal to AC common mode noise ratio (SCMR)

- Peak-Peak AC Common mode voltage

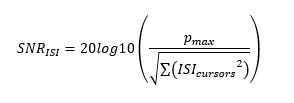

- Signal to Residual Inter symbol Interface Ratio (SNRISI)

- Difference steady-state voltage dvf

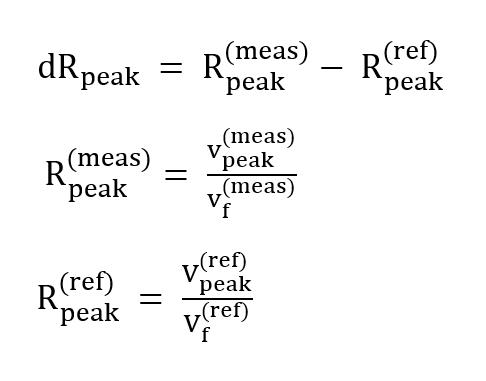

- Difference linear fit pulse peak ratio dRpeak

SCPI COMMANDS

- About SCPI command

- Socket configuration for SCPI commands

- Set or query the device name of application

- Set or query the suite name of the application

- Set or query the test name of the application

- Set or query the version name of the application

- Set or query the general parameter values

- Set or query the acquire parameter values

- Set or query the analyze parameter values

- Query the available devices in the DUT panel of the application

- Query the available suites for the selected device

- Query the list of available tests of the application

- Query the available version names of the application

- Query the list of available instruments based on the specified instrument type

- Set or query the IP address of the instrument based on the specified instrument type

- Query the information of the generated report file

- Query the information of the generated waveform files

- Query the information of the generated image files

- Query the active TekExpress application name

- Set or query the DUTID of application

- Sets or query the acquire mode status

- Set or query the execution mode status

- Generate the report for the current session

- Query the value of specified report header field in the report

- Query the value of specified result detail available in report summary/details table

- Restore the setup to default settings

- Save the setup

- Save the settings to a specified session

- Open the setup from a specified session

- Query the current setup file name

- Run/stop/pause/resume the selected measurements execution in the application

- Query the current measurement execution status

- Query whether the current setup is saved or not saved

- Exit or close the application

- Query the status of the previous command execution

- Query the last error occurred

- Set or query the popup details

- Sets or query the limit values in the limits editor window

- Set or query the waveform file recalled for the specified test name and acquire type

- Set or query the enable/disable status of Verbose function

- Query the enable or disable status of Continuous run function.

- Set or query the enable/disable status of Continuous Run function

- Set or query the continuous run duration time value

- Set or query the session create option in the continuous run function

- Set or query the View report after generating option status

- Returns the report as XML string

- Copies all the images from current run session to the given destination location

- Selects the specified test(s) and deselect all other tests

- Returns the complete information about the selected test

- Set the default session

- Save the run/config sessions

- Load the run/config session

- Delete the run/config session

- Run the run/config saved session

- Query the available list in the run/config session

- Query the current run/config session

- Override the run/config session

- Examples

Welcome

Welcome to Tektronix Real Time Oscilloscope based 400G-TXE electrical compliance test solution. The 400G-TXE is an application running on the Tektronix automation platform. The 400G-TXE evaluates the electrical PAM4 signals to the specification-mandated limits. The 400G-TXE electrical compliance test solution provides turnkey compliance testing and debug of the TX electrical properties, key to OIF (CEI-VSR/CEI-MR/CEI-LR) and IEEE (AUI/CR4/KR4) PAM4 standards. It tests the OIF-PAM4 and IEEE-PAM4 electrical standards in a simple, cost effective manner. The 400G-TXE solution offers comprehensive test automation, results margining, data logging, and results reporting in an advanced testing framework.

- The Tektronix TekExpress 400G-TXE provides an automated test solution for following specifications:

- OIF-PAM4 Specifications:

- CEI-VSR: 56G

- Host output - TP1a (Section 16.3.2, Table: 16-1)

- Module output - TP4 (Section 16.3.3, Table: 16-4)

- TP0a (Section 16.B.1.1, Table: 16-10)

- CEI-VSR: 112G

- Host output - TP1a (Section 23.3.2, Table 23-1)

- Module output - TP4 (Section 23.3.3, Table 23-4)

- TP0a (Section 23.B.1.1, Table 23-9)

- CEI-MR: Section 17.31, Tables 17-2 and 17-3

- CEI-LR: Section 21.3.1, Tables 21-2 and 21-3

- CEI-VSR: 56G

- IEEE-PAM4 50G-1, 100G-2, 200G-4, and 400G-8 Specifications:

- AUI TP0a: IEEE802.3bs Annex 120D.3.1

- AUI TP1a: IEEE802.3bs Annex 120E.3.1

- AUI TP4: IEEE802.3bs Annex 120E.3.2

- CR TP2: IEEE802.3cd Section 136.9.3

- KR TP0a: IEEE802.3cd Section 137.9.2

- IEEE-802.3ck Transmitter Electrical Specifications (100G-1, 200G-2, and 400G-4):

- AUI C2C TP0v: IEEE802.3ck, Annex 120F.3.1, Table 120F-1

- AUI C2M Host TP1a: IEEE802.3ck, Annex 120G.3.1, Table 120G-1

- AUI C2M Module TP4: IEEE802.3ck, Annex 120G.3.2, Table 120G-3

- CR TP2: IEEE802.3ck, Section 162.9, Table 162-11

- OIF-PAM4 Specifications:

- Streamlined and fully automated transmitter characterization of OIF (CEI-VSR/CEI-MR/CEI-LR) and IEEE (AUI/CR4/ KR4) PAM4 electrical transmitter specifications (chip-to-chip and chip-to-module)

- In-depth analysis and debug capabilities of electrical PAM4 signals in combination with the PAM4 software package

Getting help and support

Product documents

Use the product documents for more information on the application functions, understand the theory of operation, how to remotely program or operate the application, and do other tasks.

| To learn about | Use this document |

|---|---|

| How to use the application How to remotely control the instrument |

TekExpress 400G-TXE Help PDF version of this document can be downloaded from http://www.tek.com/downloads Compiled HTML (CHM) version is integrated with the application. Press F1 key from the keyboard to start the help. Tektronix Part Number: 077-xxxx-xx |

Conventions

This application help uses the following conventions:

- The term "Application," and "Software" refers to the TekExpress 400G-TXE application.

- The term “DUT” is an abbreviation for Device Under Test.

- The term “select” is a generic term that applies to the two methods of choosing a screen item (button control, list item): using a mouse or using the touch screen.

- A Note identifies important information.

| Icon | Description |

|---|---|

| This icon identifies important information |

| This icon identifies conditions or practices that could result in loss of data. |

| This icon identifies additional information that will help you use the application more efficiently. |

Technical support

Tektronix values your feedback on our products. To help us serve you better, please send us your suggestions, ideas, or comments on your application or oscilloscope. Contact Tektronix through mail, telephone, or the Web site. See Contacting Tektronix at the front of this document for contact information.

When you contact Tektronix Technical Support, please include the following information (be as specific as possible):

General information

- All instrument model numbers

- Hardware options, if any

- Modules used

- Your name, company, mailing address, phone number, FAX number

- Please indicate if you would like to be contacted by Tektronix about your suggestion or comments.

Application specific information

- Software version number

- Description of the problem such that technical support can duplicate the problem

- If possible, save the setup files for all the instruments used and the application

- If possible, save the TekExpress setup files, log.xml, *.TekX (session files and folders), and status messages text file

Getting started

Hardware requirements

Minimum system requirements

The following table shows the minimum system requirements to install and run the TekExpress 400G-TXE solution.

|

Component |

Description |

|---|---|

|

Oscilloscope |

|

|

Software |

|

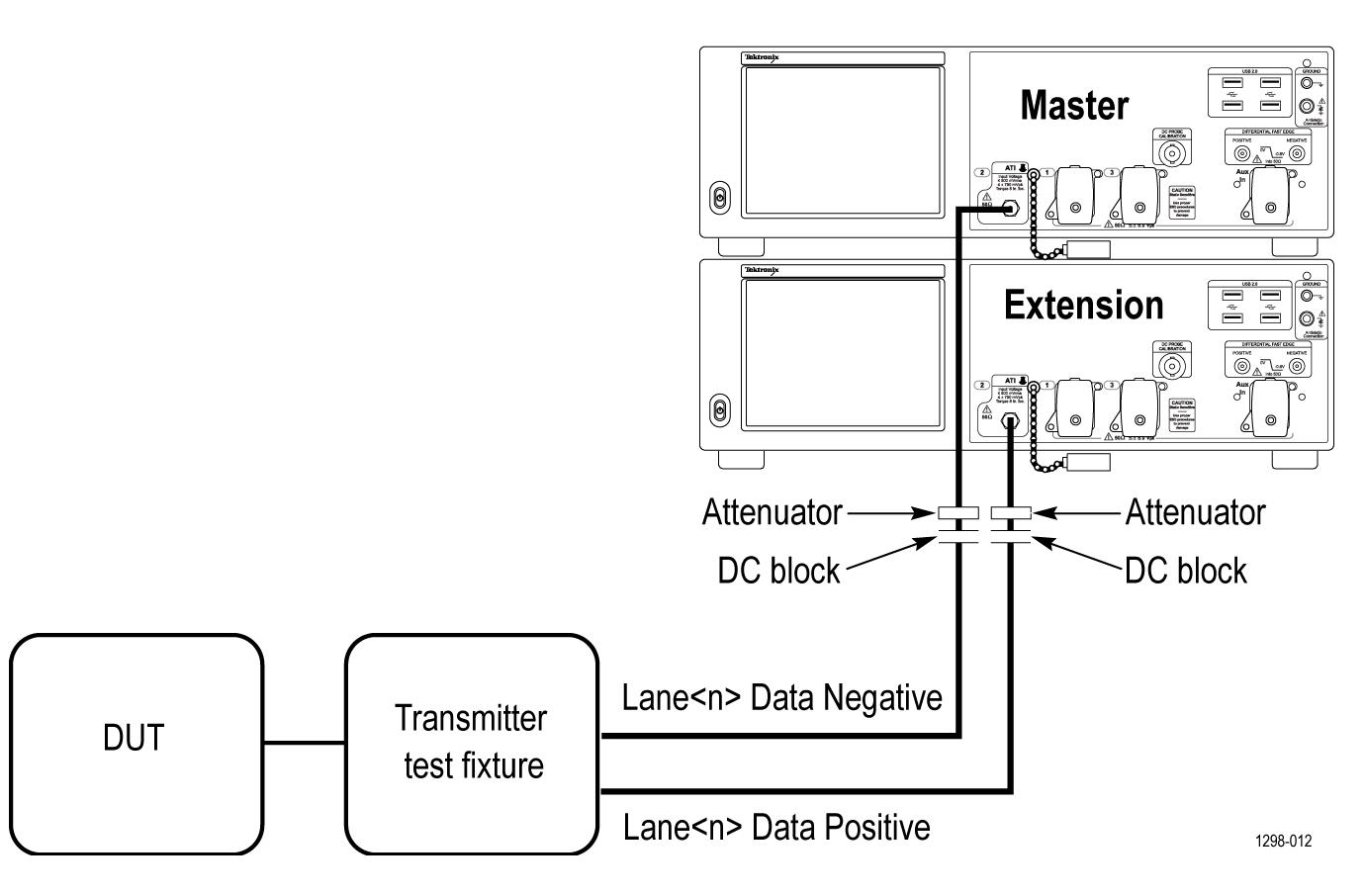

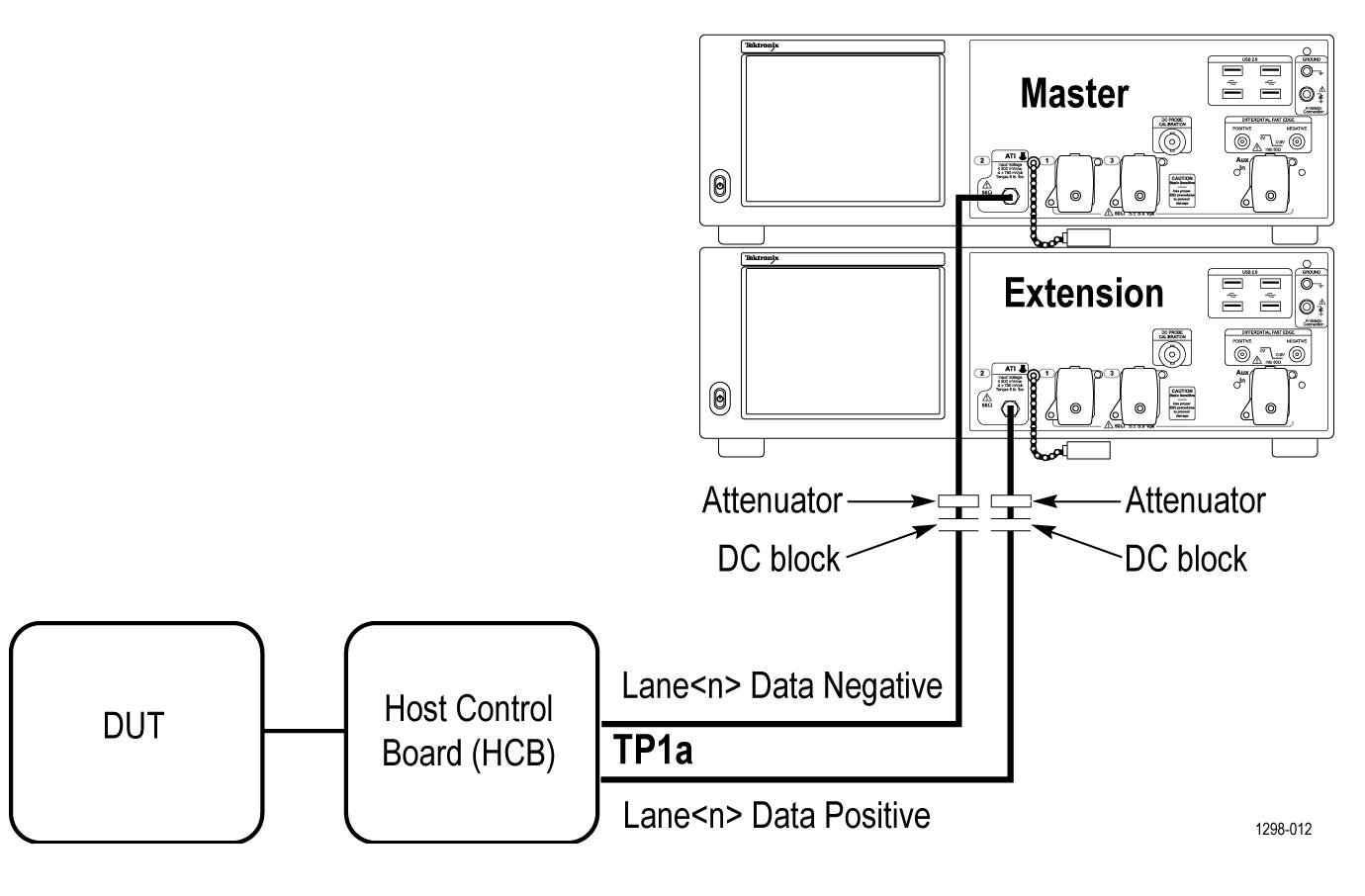

Instruments and accessories required

TekExpress 400G-TXE application is launched on DPO70K series oscilloscope. The following table lists the instruments and accessories required for this application.

| Instrument/Accessory | Model number | Quantity |

|---|---|---|

| Oscilloscope |

DPO73304DX, MSO73304DX, DPO73304SX, DPS73308SX, DPO75002SX, DPS75004SX, DPO77002SX, DPS77004SX, DPO75902SX, DPS75904SX | 2 |

| Cables | Compatible SMA cables with bandwidth > than 40 GHz (IEEE802.3cd/bs) and ≥ 59 GHz (IEEE802.3ck) for connecting single ended sources ATI channel. | 2 |

| Fixtures |

For IEEE802.3cd/bs:

| 1 |

| DC Blocks | Compatible DC block with bandwidth range 50 KHz to 65 GHz | 2 |

| Attenuator | 3, 6, or 10 dB attenuators | 2 |

Software requirements

Downloading and installing the software

Complete the following steps to download and install the latest TekExpress 400G-TXE application.

- Go to www.tek.com.

- Click Downloads. In the Downloads menu, select DOWNLOAD TYPE as Software and enter the application name in the MODEL OR KEYWORD field and click SEARCH.

- Select the latest version of software and follow the instructions to download the software. Copy the executable file into the oscilloscope.

- Double-click the executable and follow the on-screen instructions.

The software is installed at

C:\Program Files\Tektronix\TekExpress\TekExpress 400G-TXE. - Select from the Oscilloscope menu, to open the application.

Activate the license

Activate the license using the Option Installation wizard in the TekScope application:

- In the TekScope application menu bar, click . The TekScope Option Installation wizard opens.

- Push the F1 key on the oscilloscope keyboard to open the Option Installation help topic.

- Follow the directions in the help topic to activate the license.

View software version and license key details

To view version information of the application, click Options > About TekExpress.

Setting up the test environment

Compensate the signal path

- Power on and wait for the instrument to complete its warm up period before continuing with this procedure.

- Disconnect any probes you have connected to the input channels.

- Set the instrument to Menu mode.

- Select Instrument Calibration from the Utilities menu.

- Note any instructions that appear in the resulting control window.

- Click Run SPC to begin the procedure. The procedure may take several minutes to complete.

- Verify that the Status changes to Compensated after the procedure is complete. If the Calibration Status field indicates anything other than Compensated, see Signal Path Compensation Status for information on the readout and recommended action.

| Note:When making measurements at vertical scale settings less than or equal to 5 mV, you should perform the signal path compensation at least once a week. Failure to do so may result in the instrument not meeting warranted performance levels at those volts/div settings.

|

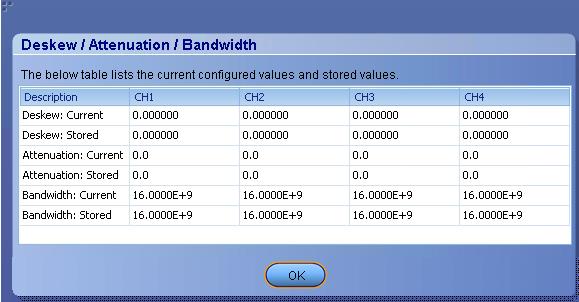

Deskew

If skew is present between positive and negative channels, then the channels need to be deskewed before being used for waveform measurements.

Apply the appropriate input attenuator such that the signal on the screen for each channel can be adjusted (using the oscilloscope's Vertical > Scale settings) to less than 10 division Pk-Pk but greater than 8 division Pk-Pk.

Use maximum instrument bandwidth so narrow noise peaks that might reach out-of-range are visible in their full amplitude, rather than limited by the post-digitizer bandwidth processing. Set the record length to 50 MSa or longer; Measure both channel 1 and channel 2 with a Measure > Amplitude > Peak - Peak to monitor that the trace is without clopping, that is the measurements don't display a warning indicating over-driven input.

TekExpress 400G-TXE provides support for channel deskew and attenuation using the following method:

- Determine what the skew is for each channel.

Please use method recommended by Tektronix. DPO70k SX oscilloscope to find the skew, for example, minimum common mode. Tektronix recommends using channel 1 as a reference with 0 skew, and entering a measured skew value in channel 2.

- From the TekScope menu, select Vertical > Deskew.

- In the Deskew/Attenuation window, click the channel 1, and set the skew to 0. Then select channel 2 button for the first channel to be deskewed.

- Click in the Ch(x) Deskew Time entry field and enter the skew. The skew can be +ve or –ve.

- Click the channel button for the next channel and repeat step 4.

- After entering the skew for all the channels that require it, from the Options menu in TekExpress 400G-TXE, select Deskew.

Figure 1. Deskew

- Click Read from Scope to read the deskew and attenuation values from the oscilloscope.

- Click View values to view the deskew, attenuation, and bandwidth values.

- When the status in the dialog box indicates the deskew is finished, click Close.

Each input channel has its own deskew settings. Deskew compensates individual channels for probes or cables of different lengths. The instrument applies the delay values after each completed acquisition. The deskew values are saved as part of the instrument setup. The deskew values for the selected channel are retained until you change the probe, you restore a saved setup, or you recall the factory setup.

| Note:If you perform the de-embed settings of all oscilloscope input connected components, then the Attenuation settings should be left at default (0 dB). |

Running tests

Select tests, set acquisition parameters, set configuration parameters, set preferences parameters, and click Start to run the tests. While tests are running, you cannot access the Setup or Reports panels. To monitor the test progress, switch between the Status panel and the Results panel.

While the tests are running, other applications may display windows in the background. The TekScope application takes precedence over other applications, but you can switch to other applications by using Alt + Tab key combination. To keep the TekExpress 400G-TXE application on top, select Keep On Top from the TekExpress Options menu.

The application displays report when the tests execution is complete.

Prerun checklist

- Make sure that the instruments are warmed up (approximately 20 minutes) and stabilized.

- Perform compensation: In the oscilloscope main menu, select . Click Help in the compensation window for steps to perform instrument compensation.

Equipment connection setup

Click to view the equipment setup diagram(s).

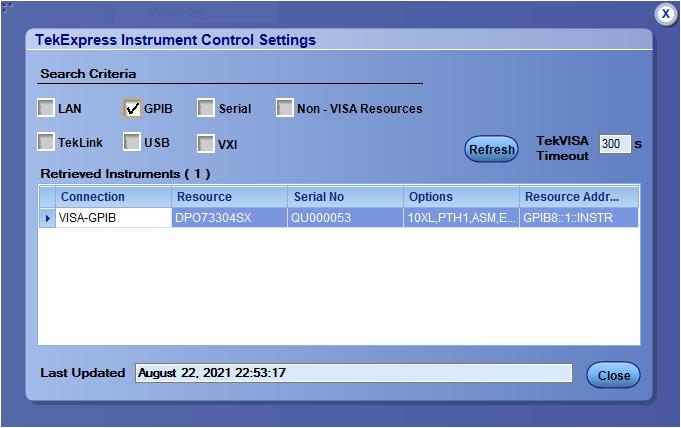

Search instruments connected to the application

| Note:The instruments required for the test setup must be connected and detected by the application, before running the test. |

- Select .

- In the Search Criteria section of the Instrument Control Settings dialog box, select the connection types of the instruments to search. Instrument search is based on the VISA layer, but different connections determine the resource type, such as LAN, GPIB, and USB. For example, if you choose LAN, the search will include all the instruments supported by the TekExpress that are communicating over the LAN.

- Click Refresh. The TekExpress application searches for the connected instruments. Search status of the instruments connected to LAN

- When the search is complete, a dialog box lists the instrument-related details based on the search criteria. For example, for the Search Criteria as GPIB, the application displays all the GPIB instruments connected to the application. TekExpress Instrument Control Settings window.

The details of the instruments are displayed in the Retrieved Instruments table. The time and date of instrument refresh is displayed in the Last Updated field.

Starting the application

To start the TekExpress 400G-TXE, select from the oscilloscope menu bar Applications/Analyze > TekExpress 400G-TXE.

During start, a "My TekExpress" folder is created in the Documents folder of the current user and gets mapped to "X" drive. When the application is closed properly, the "X" drive gets unmapped. Session files are then stored inside the X:\400G-TXE folder. If this file is not found, the application runs an instrument discovery program to detect connected instruments before starting TekExpress 400G-TXE.

To keep the TekExpress 400G-TXE application on top of any application, select Keep On Top from the options menu. If the application goes behind the oscilloscope application, select Applications/Analyze >TekExpress 400G-TXE to bring the application to the front.

Application controls

| Item | Description | ||

|---|---|---|---|

Options menu | Menu to display global application controls. | ||

Test panel | Controls that open tabs for configuring test settings and options. | ||

Start / Stop button  | Use the Start button to start the test run of the measurements in the selected order. If prior acquired measurements are not cleared, then new measurements are added to the existing set. The button toggles to the Stop mode while tests are running. Use the Stop button to abort the test. | ||

Pause / Continue button | Use the Pause button to pause the acquisition. When a test is paused, this button changes as Continue. | ||

Clear button | Use the Clear button to clear all existing measurement results. Adding or deleting a measurement, or changing a configuration parameter of an existing measurement, also clears measurements. This is to prevent the accumulation of measurement statistics or sets of statistics that are not coherent. This button is available only on Results panel.

| ||

| Application window move icon | Place the cursor over the top of the application window to move the application window to the desired location | ||

| Minimize icon | Minimizes the application. | ||

| Close icon | Close the application. | ||

| Mini view / Normal view | Mini view displays the run messages with

the time stamp, progress bar, Start / Stop button, and Pause /

Continue button. The application moves to mini view when you click

the Start button. |

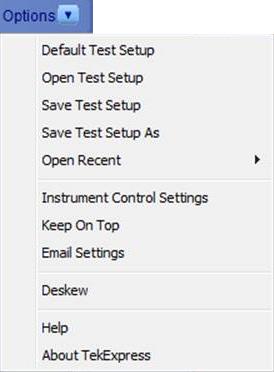

Options menu functions

To access the Options menu, click

| Menu | Function |

|---|---|

| Default Test Setup | Opens a new test setup with default configurations. |

| Open Test Setup | Opens a previously saved test setup. Displays the list of previously saved test setup file names. Make the selection and click OK to open the test setup. |

| Save Test Setup | Saves the current test configurations with the specified file name. |

| Save Test Setup As | Saves the current test setup with a different file name or file type. |

| Open Recent | Displays the recently opened test setup file names. Make the selection and click OK to open the test setup. |

| Instrument Control Settings |

Detects, lists, and refreshes the connected instruments found on the specified connections (LAN, GPIB, USB, Serial, Non-VISA Resources, TekLink, and VXI). |

| Keep On Top |

Always keeps the TekExpress 400G-TXE application on top of all the applications. |

| Email Settings | Configures email options for test run and result notifications. |

| Deskew | Loads oscilloscope channel deskew settings into the application. |

| Help | Displays the TekExpress 400G-TXE help. |

| About TekExpress |

Displays the application name, version, and hyperlink to end the user license agreement. |

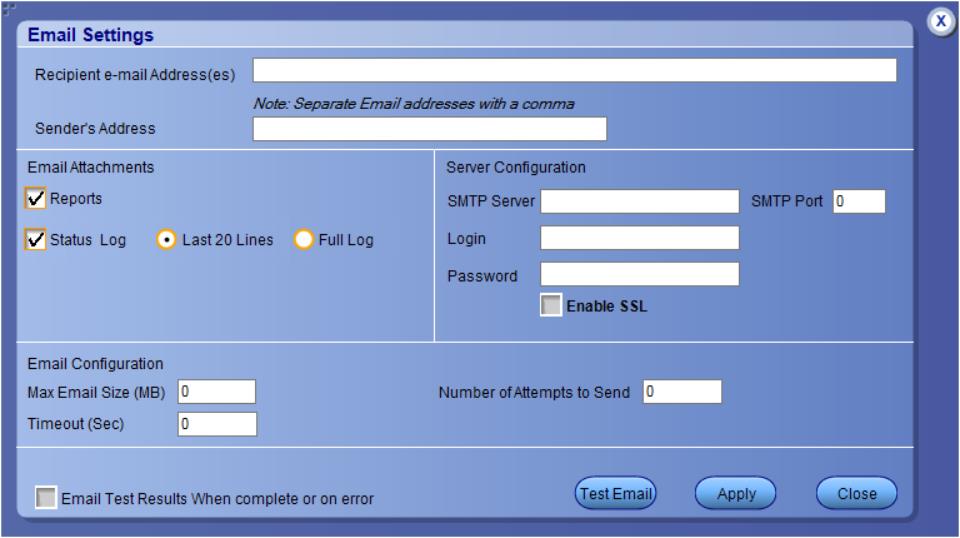

Configure email settings

Use the Email Settings utility to get notified by email when a measurement completes or produces any error condition. Follow the steps to configure email settings:

- Select Options > Email Settings to open the Email Settings dialog box.

- (Required) For Recipient email Address(es), enter one or more recipient email addresses. To include multiple addresses, separate the addresses with commas.

- (Required) For Sender’s Address, enter the email address used by the instrument. This address consists of the instrument name, followed by an underscore, followed by the instrument serial number, then the @ symbol, and the email server ID. For example: [email protected].

- (Required) In the Server Configuration section, type the SMTP Server address of the Mail server configured at the client location, and the SMTP Port number, in the corresponding fields.

If this server requires password authentication, enter a valid login name, password, and host name in the corresponding fields.

Note:If any of the above required fields are left blank, the settings will not be saved, and email notifications will not be sent.

Note:If any of the above required fields are left blank, the settings will not be saved, and email notifications will not be sent. - In the Email Attachments section, select from the following options:

- Reports: Select to receive the test report with the notification email.

- Status Log: Select to receive the test status log with the notification email. If you select this option, then also select whether you want to receive the full log or just the last 20 lines.

- In the Email Configuration section:

- Enter a maximum file size for the email message. Messages with attachments larger than this limit will not be sent. The default is 0 MB.

- Enter the number in the Number of Attempts to Send field, to limit the number of attempts that the system makes to send a notification. The default is 1. You can also specify a timeout period.

- Select the Email Test Results When complete or on error check box. Use this check box to quickly enable or disable email notifications.

- To test your email settings, click Test Email.

- To apply your settings, click Apply.

- Click Close when finished.

TekExpress instrument control settings

Use the TekExpress Instrument Control Settings dialog box to search the instruments (resources) connected to the application. You can use the Search Criteria options to search the connected instruments depending on the connection type. The details of the connected instrument is displayed in the Retrieved Instruments window.

To access, click Options > Instrument Control Settings. Select GPIB as search criteria for TekExpress application and click Refresh. The connected instruments displayed in the Retrieved Instruments window and can be selected for use under Global Settings in the test configuration section.

See also

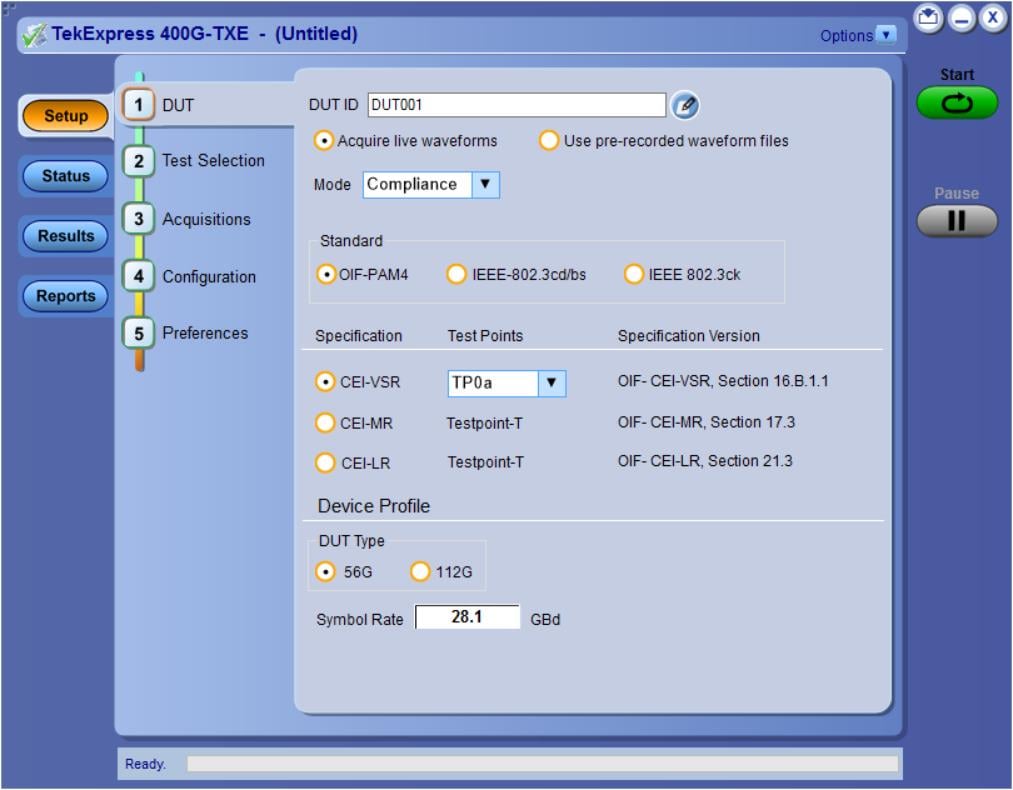

Setup panel: Configure the test setup

The Setup panel contains sequentially ordered tabs that help you guide through the test setup and execution process.

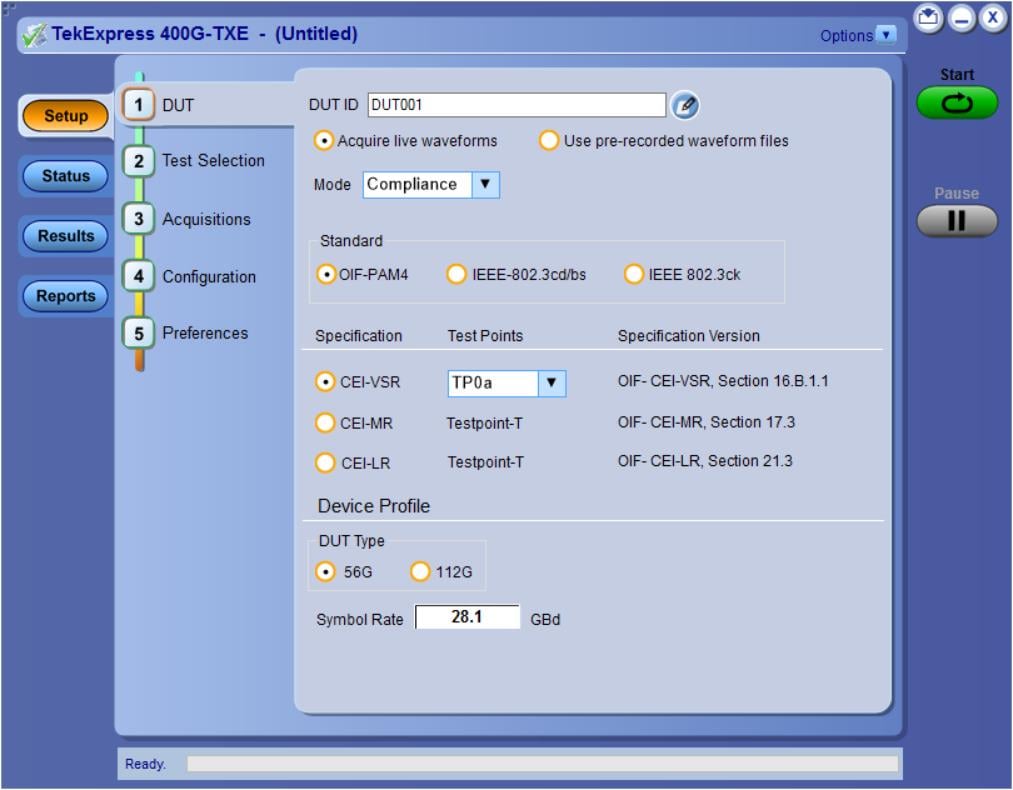

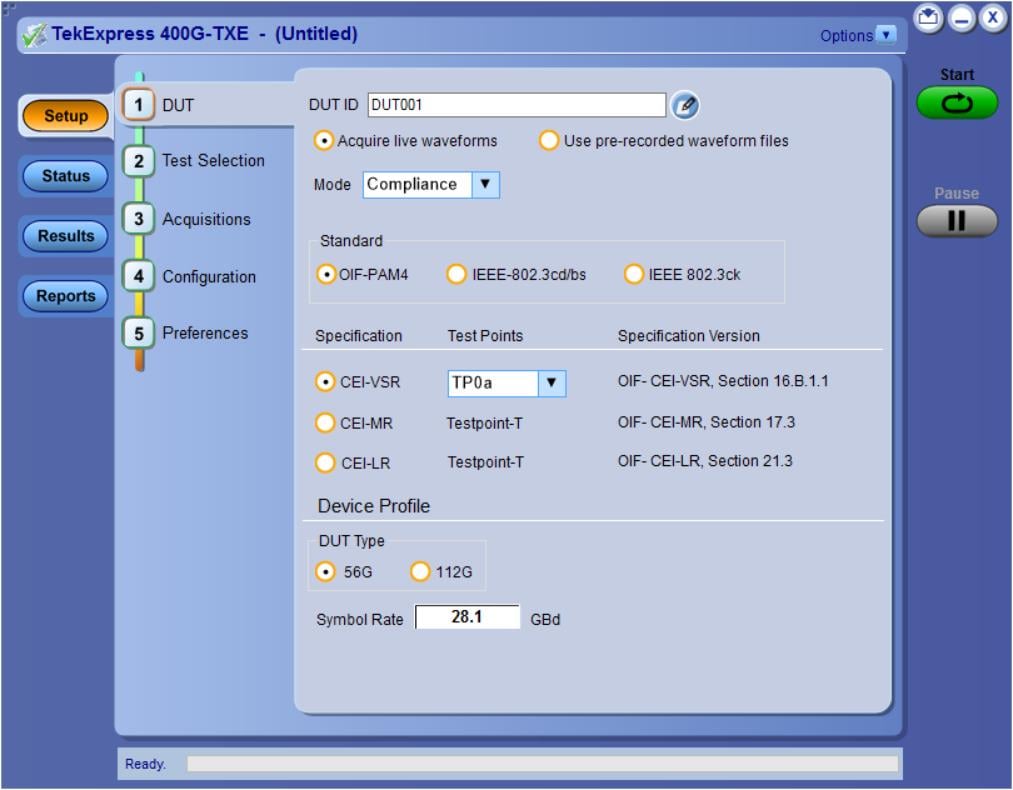

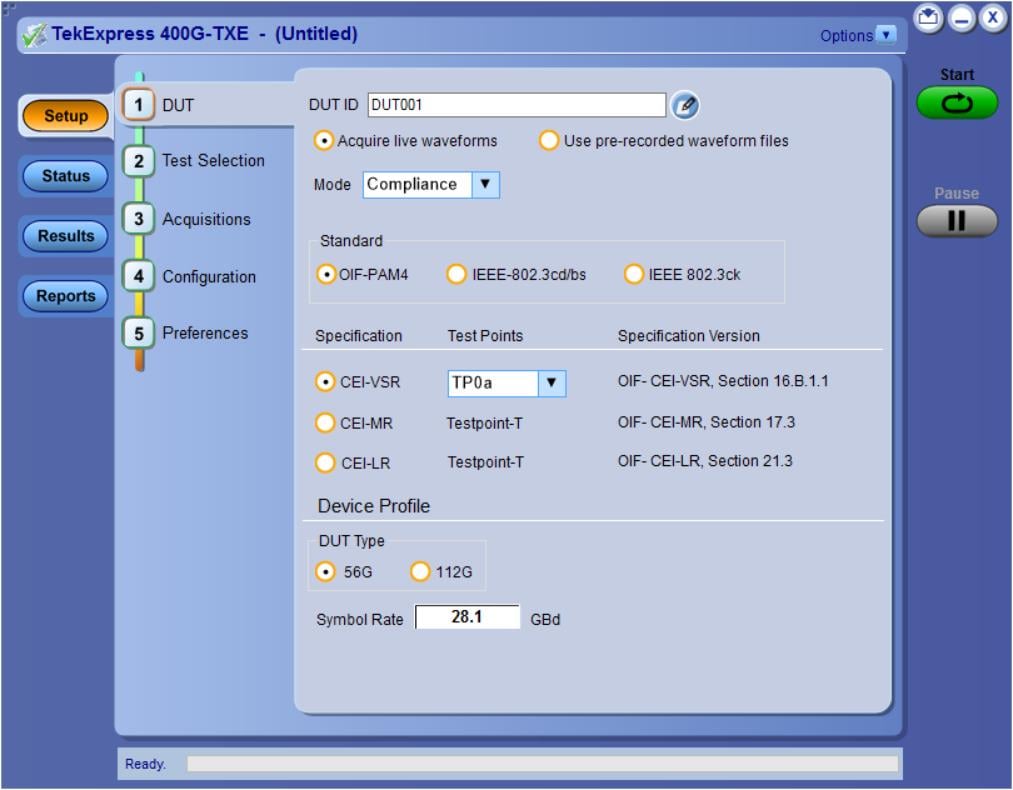

DUT: Set DUT settings

Use the DUT tab to select parameters for the device under test. These settings are global and apply to all tests of current session. DUT settings also affect the list of available tests in the Test Selection tab.

Click Setup > DUT to access the DUT parameters:

| Setting | Description | |

|---|---|---|

| DUT ID |

Adds an optional text label for the DUT to reports. The default value is DUT001. The maximum number of characters is 32. You cannot use the following characters in an ID name: (.,..,...,\,/:?”<>|*) | |

| Opens Comments dialog box to enter text to add to the report. Maximum size is 256 characters. To enable or disable comments appearing on the test report, see Select report options. | |

| Acquire live waveforms | Acquire active signals from the DUT for measurement and analysis. | |

| Use pre-recorded waveform files | Run tests on a saved waveform. Select to recall a saved test setup. | |

| Mode |

| |

| Standard |

| |

| Specification |

For OIF-PAM4 standard

For IEEE-802.3cd/bs standard

For IEEE 802.3ckTM standard

| |

| Test Points |

For OIF-PAM4 standard

For IEEE-802.3cd/bs standard

For IEEE 802.3ck standard

| |

| Specification Version | Displays the specification version for the selected Specification and Test Points. | |

| Device Profile | ||

| DUT Type | Select the DUT type

| |

| Symbol Rate | Set the symbol rate to be tested. | |

| Crosstalk Source | Select crosstalk source when a cross talk generator is connected. This is applicable for eye measurements only. | |

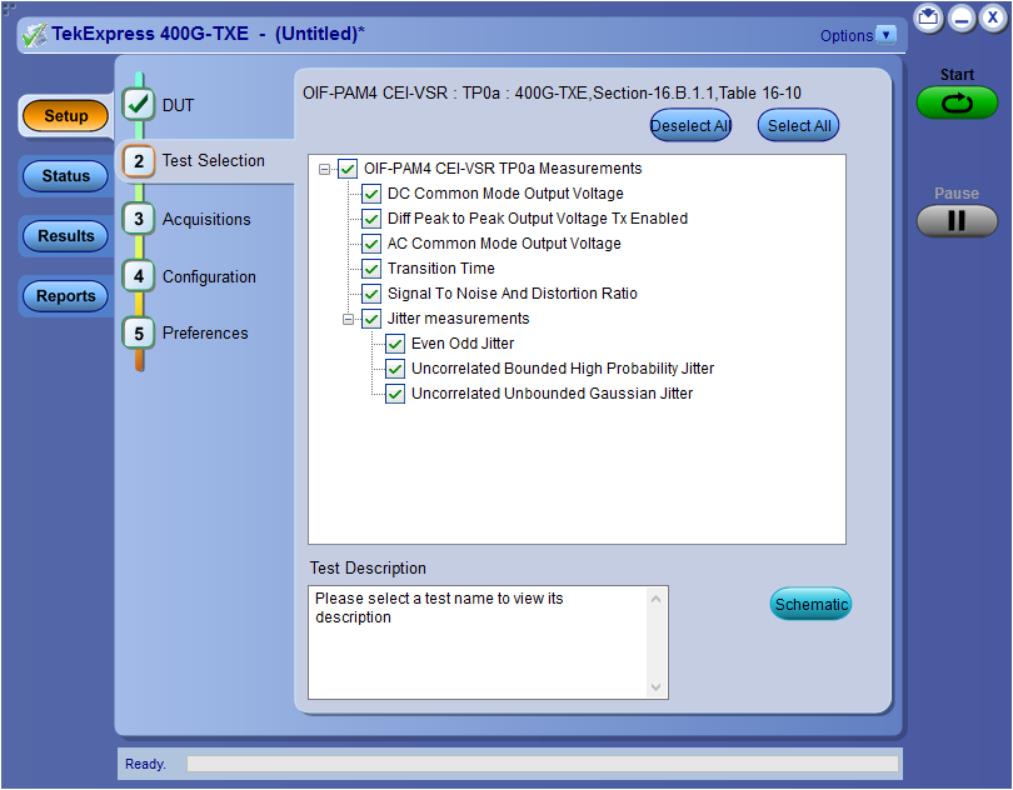

Test Selection: Select the tests

Use the Test Selection tab to select the tests. The test measurements available depends on the settings selected in the DUT tab.

| Setting | Description |

|---|---|

| Tests | Select or clear a test. Highlight a test to show details in the Test Description pane. |

| Test Description | Shows brief description of the highlighted test in the Test field. |

| Deselect All | Click to clear all tests. |

| Select All | Click to select all tests. All tests are selected by default. |

| Schematic | Click to display the schematic diagram of the DUT test setup for the selected test. Use the diagram to verify the test setup before running the test. |

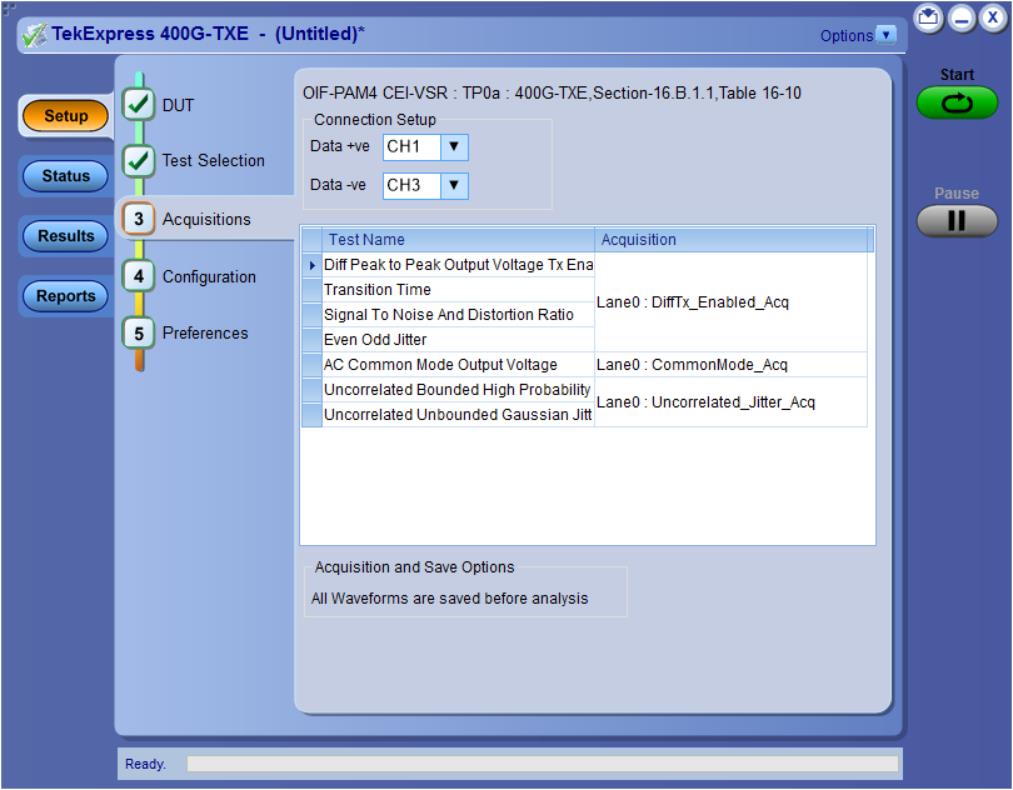

Acquisitions: Set waveform acquisition settings

Use Acquisitions tab to view the test acquisition parameters. The contents displayed on this tab depends on the DUT type and the tests selected.

| Note:400G-TXE application acquires all waveforms needed by each test before performing the analysis. |

| Setting | Description |

|---|---|

| Connection Setup | |

| Data +ve | Select the source channel for data positive. |

| Data -ve 1 | Select the source channel for data negative. |

| Acquisition and Save Options | All Waveforms are saved before analysis |

TekExpress 400G-TXE application saves all

acquisition waveforms to files by default. Waveforms are saved in a unique folder for

each session (a session is started when you click the Start button). The folder path is

X:\TekExpress 400G-TXE\Untitled Session\<dutid>\<date>_<time>.

Images created for each analysis, XML files with result values, reports, and other

information specific to that particular execution are also saved in this folder.

Saving a session moves the session file contents from the Untitled Session folder to the specified folder name and changes the session name to the specified name.

400G TX CK Measurement waveform naming

When user captures the signals manually, the naming convention and ordering to load the waveform to TekExpress Acquisition panel should be followed as per below table.

| Note:Lane and Run details are must for all the measurement in waveform name. |

| Test Name | Waveform Naming Convention | Waveform Naming Example |

|---|---|---|

|

C2C: Signal to AC Common mode noise Ratio (SCMR) |

Input: Two waveforms Append 'Diff'/'CommonMode' |

|

|

C2C, C2M Host/Module, CR: Peak-to-Peak AC-Common mode Voltage | Append 'LF'/'FB' | DUT001_LF_Lane0_Run1.wfm |

|

C2C, CR: Coefficient Range |

Input: 3 waveforms

|

|

|

C2C: Normalized coefficient step size |

Input: 4 waveforms

|

|

|

C2M Host: Transition Time C2M Module: Diff Peak to Peak Output Voltage Tx Enabled |

Append 'Short’/ ‘Long’, Lane and Run details to the waveform name | Short_Lane0_Run1.wfm, Long_Lane0_Run1.wfm |

|

C2M Host: VEC,EH |

Inputs: 2 waveforms,

|

|

|

C2M Module: Far End VEC, Far End EH | These measurements have two modes Short and Long. If Both is selected, then user need to load Four waveforms in below order.

|

|

|

C2M Module: Near End VEC, Near End EH | These measurements have two modes Short and Long. If Both is selected, then user need to load Four waveforms in below order.

|

|

| CR: Coefficient Range |

Input: 2 waveforms,

|

|

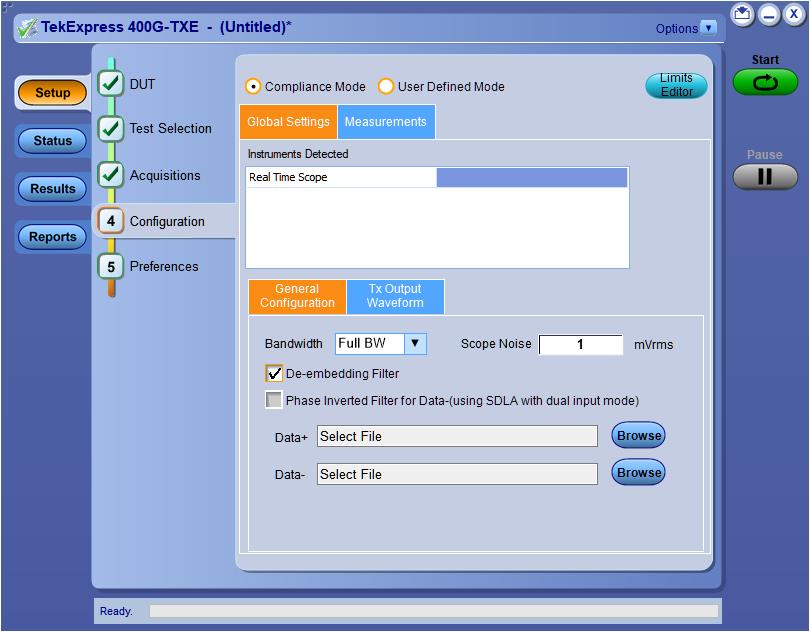

Configuration: Set measurement limits for tests

Use Configuration tab to view and configure the Global Settings and the measurement configurations. The measurement specific configurations available in this tab depends on the selections made in the DUT panel and Test Selection panel.

| Settings | Description |

|---|---|

| Mode |

Determines whether test parameters are in compliance or can be edited.

|

| Limit Editor |

Displays the upper and lower limits for the applicable measurement using different types of comparisons. In the Compliance Mode, you can view the measurement high and low limits used for the tests displayed in the tree view of the Measurements tab. When running tests in User Defined Mode, you can edit the limit settings in the Limits Editor. The second table shows the tests with the limits calculated dynamically as per the specification.

|

| Setting | Description | ||||

|---|---|---|---|---|---|

| Compliance Mode | Select compliance mode. By default, Compliance Mode is selected. | ||||

| User Defined Mode | Select user defined mode | ||||

| Global Settings | |||||

| Instruments Detected |

Displays the instruments connected to this application. Click the instrument name to open a list of available (detected) instruments. Select and click Refresh to update the instrument list.

| ||||

| General Configuration | |||||

| Bandwidth | Select the bandwidth limit for the oscilloscope. | ||||

| Scope Noise |

Enter the scope noise in mV. Scope noise the standard deviation of the noise of the oscilloscope. Scope noise is important for many of the electrical measurements. To ensure accurate measurement results, measure the scope noise manually and set the compensation value in the TekExpress. For more information on how to measure and apply scope noise, please refer PAM4 Analysis tool help document. | ||||

| De-embedding Filter | Select to apply the de-embedding filter file for Data Positive and Data Negative. | ||||

| Phase Inverted Filter for Data- (using SDLA with dual input mode) | Select this option if the filter is created from SDLA using Dual input option. The negative channel filter must be phase inverted when you select this option. | ||||

| Data+ | Click Browse and select the de-embedding filter file (.flt) for data positive signal. | ||||

| Data- | Click Browse and select the de-embedding filter file (.flt) for data negative signal. | ||||

| Tx Output Waveform | |||||

| Samples per Symbol (M) |

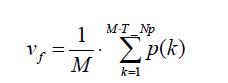

Select the number of samples per symbol for calculating the Tx out waveform parameters. If the acquired signal has less samples than specified, re-sampling is done to achieve the required samples per symbol. By default it is 32. | ||||

| Linear Pulse Length (Np) |

Select the linear fit pulse curve length in Unit intervals (UI). It is recommended to use higher value for better accuracy. The analysis time is more when you select higher value. | ||||

| Linear Pulse Delay (Dp) (Dp<Np) | Select the delay of the linear fit pulse. | ||||

| Eye Configuration | |||||

| CTLE Filter File | Select the CTLE Filter File. Compliance mode

User Defined mode

| ||||

| Target BER (1e-) /Target BER (10^-) |

Select the Target BER (1e-). As per the compliance, Target BER should be set to 1e-5 and 1e-6 for IEEE and OIF standards respectively. If the Target BER is set to higher values, more time is required to analyse the data. You can select BER of 1e-5 for quicker analysis. Select the Target BER (10^-). As per the compliance, Target BER values should be set to 4.00 to 6.00 for IEEE802.3ck standards respectively. | ||||

| Mask Width | Select the mask width in Unit intervals (UI). This configuration is for Eye symmetry mask width measurement only. | ||||

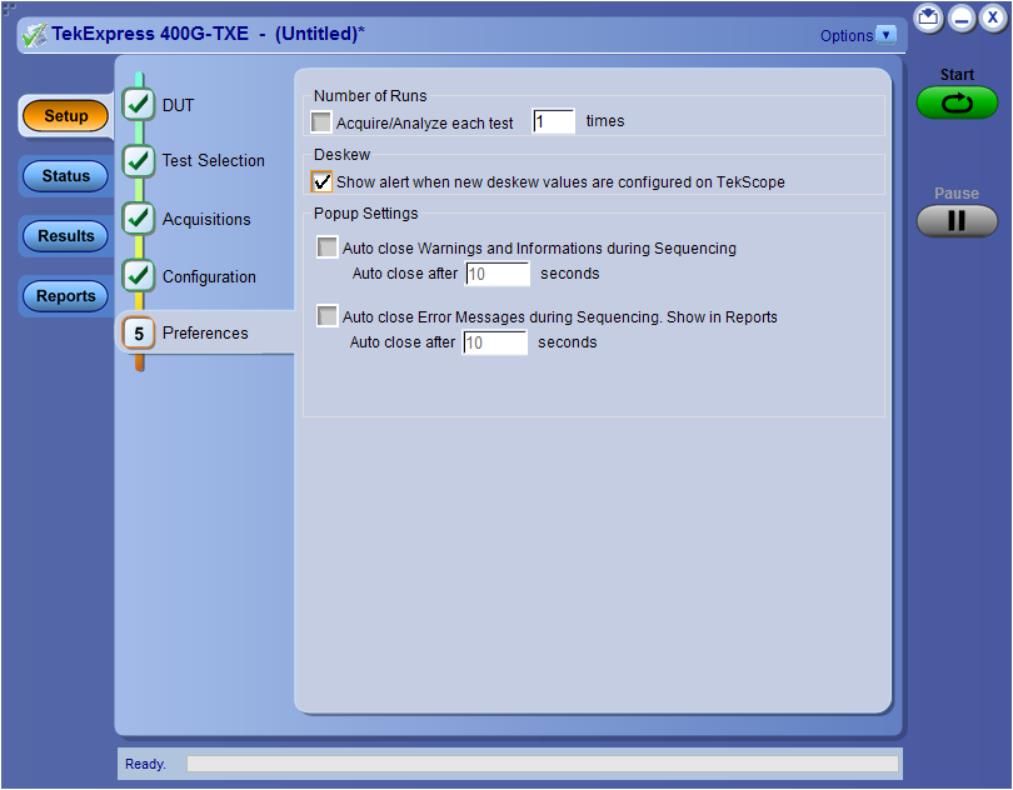

Preferences: Set the test run preferences

Use Preferences tab to set the application action on completion of a measurement. The Preferences tab has the feature to enable or disable certain options related to the measurement execution.

Refer the below table for the options available in the Preferences tab:

| Setting | Description |

|---|---|

| Number of Runs | |

| Acquire/Analyze each test <no> times (not applicable to Custom Tests) |

Select to repeat the test run by setting the number of times. By default, the check box is enabled. |

| Deskew | |

| Show alert when new deskew values are configured on TekScope | |

| Popup Settings | |

| Auto close Warnings and informations during Sequencing Auto close after <no> seconds | Select to close the warnings and information window automatically after the specified amount of time. Specify the time in seconds using the edit box. |

| Auto close Error Messages during Sequencing. Show in Reports Auto close after <no> seconds | Select to close the error message window automatically after the specified amount of time. Specify the time in seconds using the edit box. |

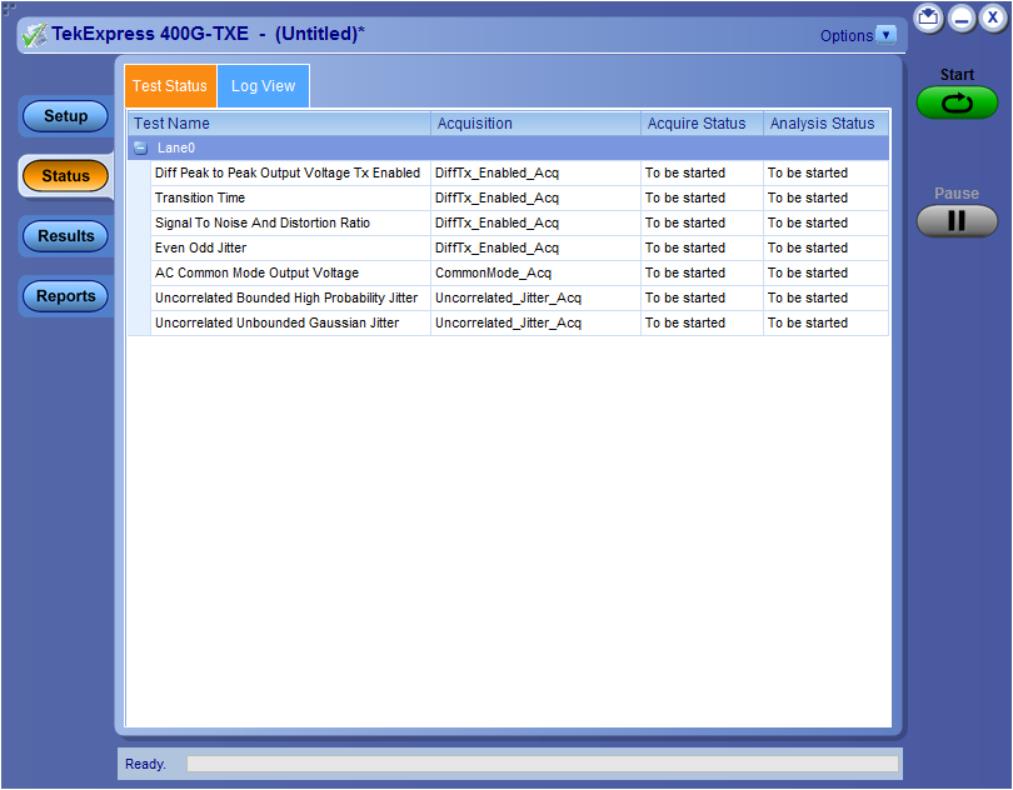

Status panel: View the test execution status

The Status panel contains the Test Status and Log View tabs, which provides status on the test acquisition and analysis (Test Status) and listing of test tasks performed (Log View tab). The application opens the Test Status tab when you start to execute the test. Select the Test Status or the Log View tab to view these items while the test execution is in progress.

View test execution status

The tests are grouped and displayed based on the Clock and Data lane. It displays the tests along with the acquisition type, acquire, and analysis status of the tests. In pre-recorded mode, Acquire Status is not valid.

The Test Status tab presents a collapsible table with information about each test as it is running. Use the symbols to expand (

| Control | Description |

|---|---|

| Test Name | Displays the measurement name. |

| Acquisition | Describes the type of data being acquired. |

| Acquire Status | Displays the progress state of the acquisition:

|

| Analysis Status | Displays the progress state of the analysis:

|

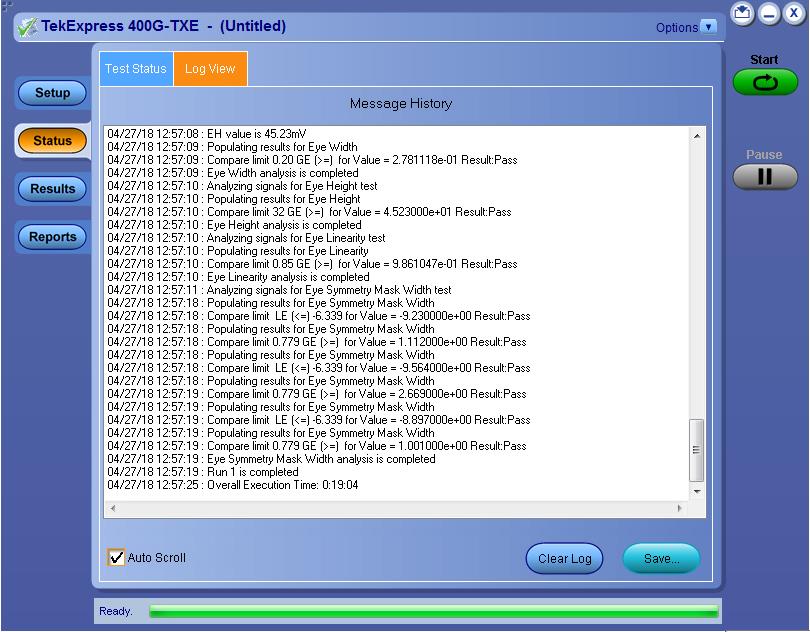

View test execution logs

The Test Status tab displays the detailed execution status of the tests. Also, displays each and every execution step in detail with its timestamp information. The log details can be used to troubleshoot and resolve any issue/bug which is blocking the test execution process.

| Control | Description |

|---|---|

| Message History | Lists all the executed test operations and timestamp information. |

| Auto Scroll |

Enables automatic scrolling of the log view as information is added to the log during the test execution. |

| Clear Log | Clears all the messages from the log view. |

| Save |

Saves the log file into a text file format. Use the standard Save File window to navigate to and specify the folder and file name to save the log text. |

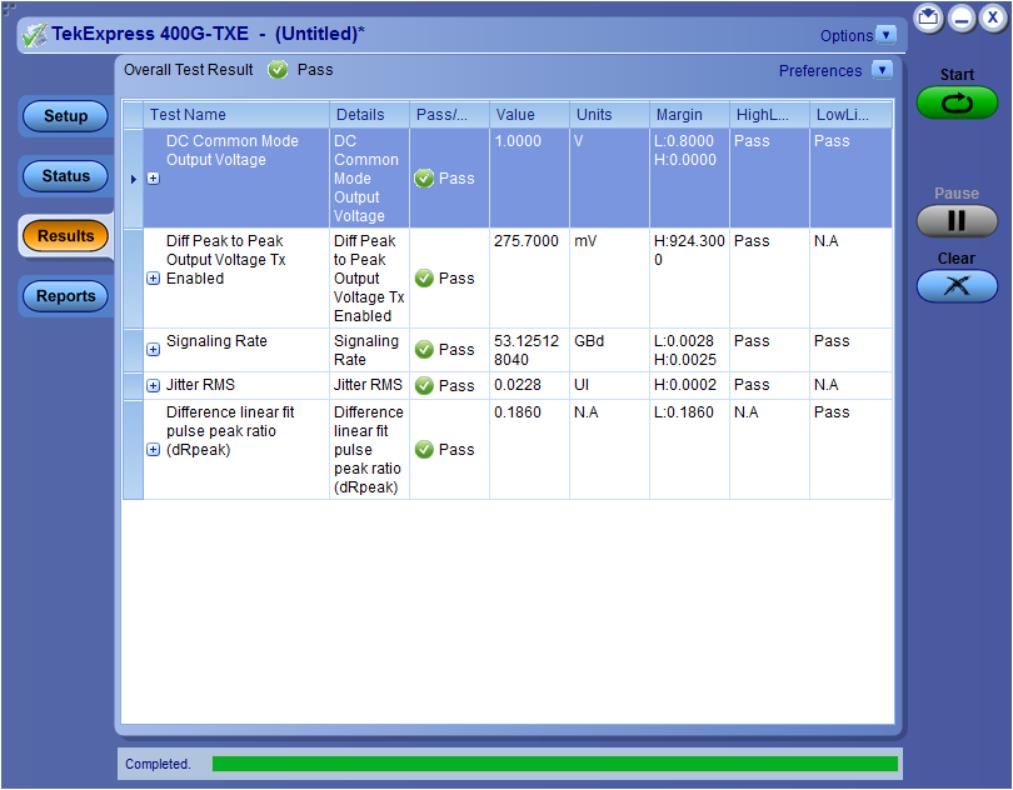

Results panel: View summary of test results

When a test execution is complete, the application automatically opens the Results panel to display a summary of test results.

In the Results table, each test result occupies a row. By default, results are displayed in summary format with the measurement details collapsed and with the Pass/Fail column visible.

Click ![]() icon on each measurement in the row to expand and to display the minimum and maximum parameter values of the measurement.

icon on each measurement in the row to expand and to display the minimum and maximum parameter values of the measurement.

Filter the test results

- To remove or restore the Pass/Fail column, select .

- To collapse all expanded tests, select .

- To expand all the listed tests, select View Results Details from the Preferences menu in the upper right corner.

- To enable or disable the wordwrap feature, select .

- To view the results grouped by lane or test, select the corresponding item from the Preferences menu.

- To expand the width of a column, place the cursor over the vertical line that separates the column from the column to the right. When the cursor changes to a double-ended arrow, hold down the mouse button and drag the column to the desired width.

- To clear all test results displayed, click Clear.

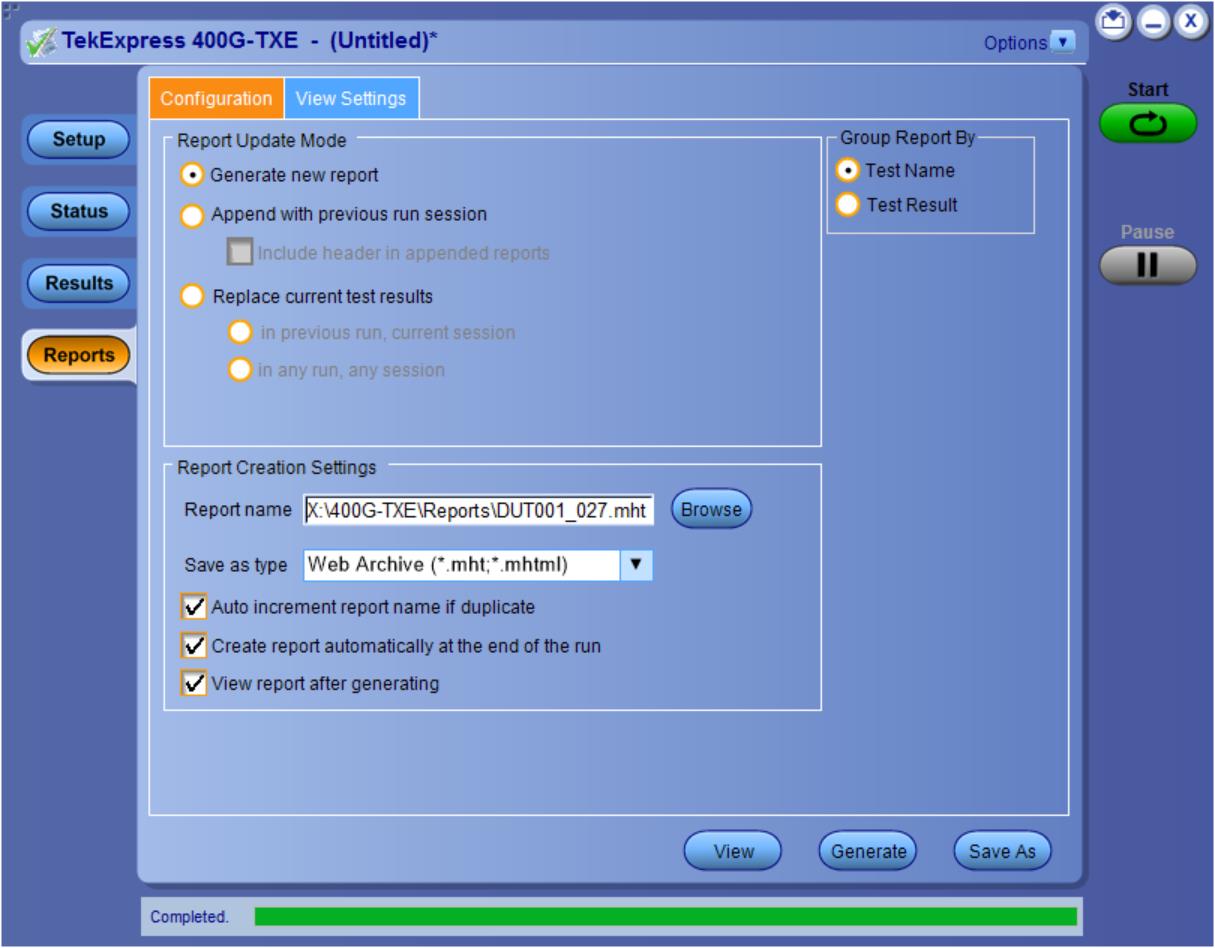

Reports panel: Configure report generation settings

Click Reports panel to configure the report generation settings and select the test result information to include in the report. You can use the Reports panel to configure report generation settings, select test content to include in reports, generate the report, view the report, browse for reports, name and save reports, and select report viewing options.

Report configuration settings

The Configuration tab describes the report generation settings to configure the Reports panel. Select report settings before running a test or when creating and saving test setups. Report settings configured are included in saved test setups.

| Control | Description | ||

|---|---|---|---|

| View | Click to view the most current report. | ||

| Generate | Generates a new report based on the current analysis results. | ||

| Save As | Specify a name for the report. | ||

| Report Update Mode Settings | |||

| Generate new report | Each time when you click Run and when the test execution is complete, it will create a new report. The report can be in either .mht, .pdf, or .csv file formats. | ||

| Append with previous run session | Appends the latest test results to the end of the current test results report. Each time when you click this option and run the tests, it will run the previously failed tests and replace the failed test result with the new pass test result in the same report. | ||

| Include header in appended reports | Select to include header in appended reports. | ||

| Replace current test results | Replaces the previous test results with the latest test results. Results from newly added tests are appended to the end of the report. | ||

| In previous run, current session |

Select to replace current test results in the report with the test result(s) of previous run in the current session. | ||

| In any run, any session | Select to replace current test results in the report with the test result(s) in the selected run session’s report. Click and select test result of any other run session. | ||

| Report Creation Settings | |||

| Report name |

Displays the name and path of the <Application Name> report. The default location is at To change the report name or location, do one of the following:

Be sure to include the entire folder path, the file name, and the file extension. For example:

Open an existing report Click Browse, locate and select the report file and then click View at the bottom of the panel. | ||

| Save as type |

Saves a report in the specified file type, selected from the drop-down list. The report is saved in .csv, .pdf, or .mht.

| ||

| Auto increment report name if duplicate |

Sets the application to automatically increment the name of the report file if the application finds a file with the same name as the one being generated. For example: DUT001, DUT002, DUT003. This option is enabled by default. | ||

| Create report automatically at the end of the run | Select to create the report with the settings configured, at the end of run. | ||

| View report after generating |

Automatically opens the report in a Web browser when the test execution is complete. This option is selected by default. | ||

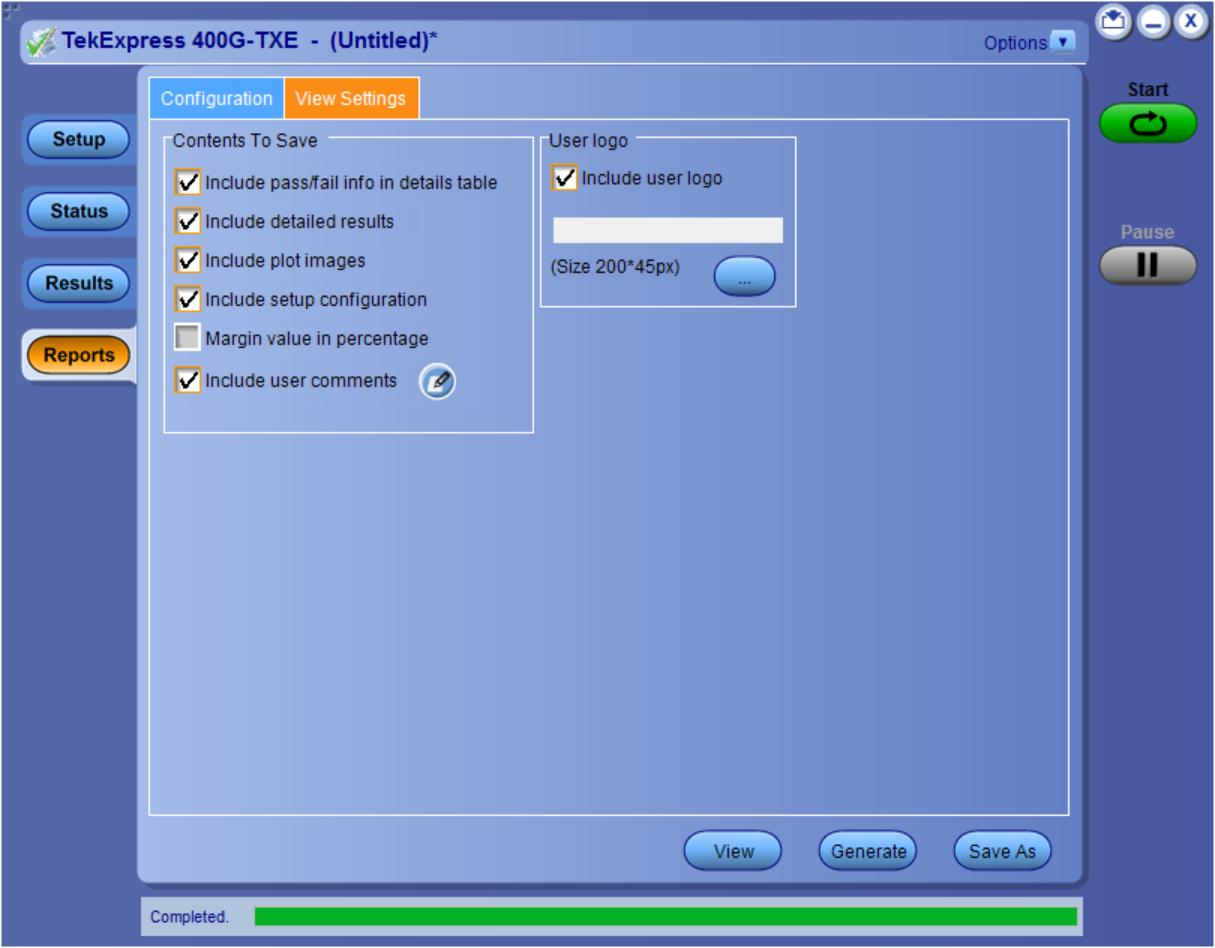

Configure report view settings

The View Settings tab describes the report view settings to configure the Reports panel. Select report view settings before running a test or when creating and saving test setups. Report settings configured are included in saved test setups.

| Control | Description |

|---|---|

| Include setup configuration | Sets the application to include hardware and software information in the summary box at the top of the report. Information includes: the oscilloscope model and serial number, the oscilloscope firmware version, and software versions for applications used in the measurements. |

| Group Report By | |

| Test Name | Select to group the test results based on the test name in the report.. |

| Test Result | Select to group the test results based on the test result in the report. |

| Include user logo | Select to add your logo in the generated report. When selected, specify the logo file path in the Image file path option. Click browse and select the logo image. |

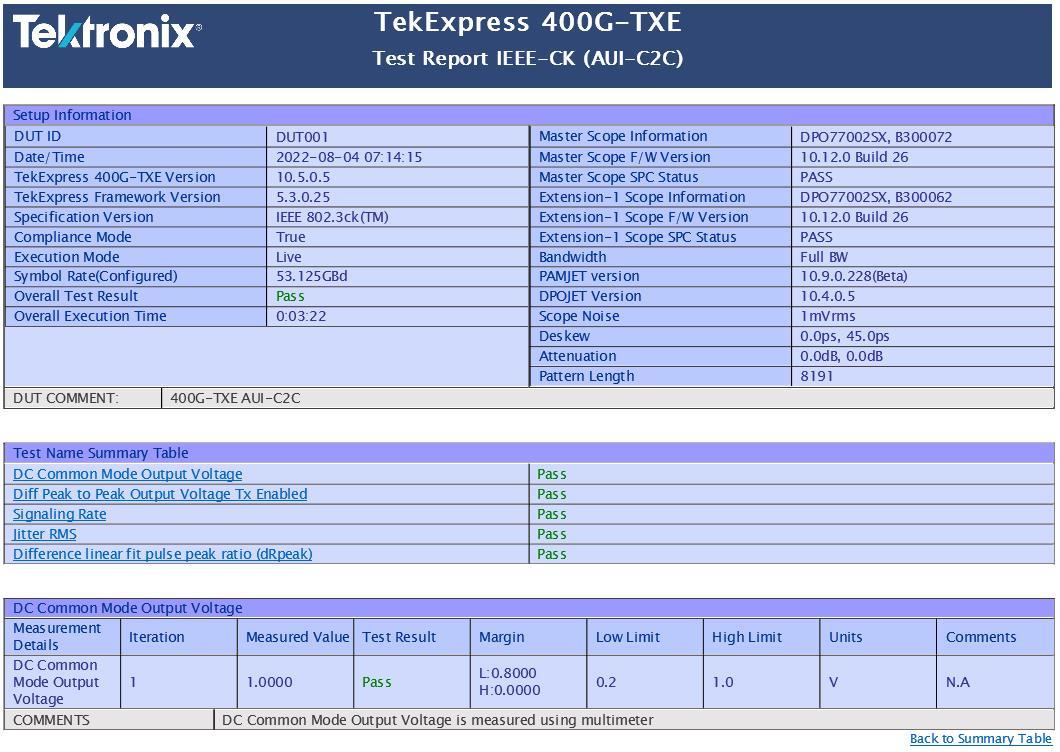

View a generated report

Sample report and its contents

A report shows detailed results and plots, as set in the Reports panel.

- Setup Information

- The summary box at the beginning of the report lists setup configuration information. This information includes the oscilloscope model and serial number, optical module model and serial number, and software version numbers of all associated applications.

- Test Name Summary Table

- The test summary table lists all the tests which are executed with its result status.

- Measurement

- The measurement table displays the measurement related details with its parameter value.

- User comments

-

If you had selected to include comments in the test report, any comments you added in the DUT tab are shown at the top of the report.

Saving and recalling test setup

Overview

You can save the test setup and recall it later for further analysis. Saved setup includes the selected oscilloscope, general parameters, acquisition parameters, measurement limits, waveforms (if applicable), and other configuration settings. The setup files are saved under the setup name at X:\TekExpress 400G-TXE

- Recall a saved configuration.

- Run a new session or acquire live waveforms.

- Create a new test setup using an existing one.

- View all the information associated with a saved test, including the log file, the history of the test status as it executed, and the results summary.

- Run a saved test using saved waveforms.

| Note:Images that are shown in this Saving and recalling test setup chapter are for illustration purpose only and it may vary depending on the TekExpress application. |

Save the configured test setup

You can save a test setup before or after running a test. You can create a test setup from already created test setup or using a default test setup. When you save a setup, all the parameters, measurement limits, waveform files (if applicable), test selections, and other configuration settings are saved under the setup name. When you select the default test setup, the parameters are set to the application’s default value.

- Select Options > Save Test Setup to save the opened setup.

- Select Options

> Save Test Setup As to save the setup with different name.

Load a saved test setup

To open (load) a saved test setup, do the following:

- Select Options

> Open Test Setup.

- From the File Open menu, select the setup file name from the list and click Open.

| Note:Parameters that are set for the respective test setup will enable after opening the file. |

Perform a test using pre-run session files

- Select Options

> Open Test Setup.

- From the File Open menu, select a setup from the list and then click Open.

Note:Parameters that are set for the respective test setup will enable after opening the file.

Note:Parameters that are set for the respective test setup will enable after opening the file. - Switch the mode to Use Pre-recorded waveform files in the DUT panel.

- Select the required waveforms from the selected setup in the Acquisitions tab and click Start.

- The selected waveform file can be removed/replaced by clicking on the (

- After successful completion of the test, the waveform report files are stored at

X:\<Application Name>\Reports.

- The overall test result status after completion of the test execution is displayed in the Results Panel.

Save the test setup with a different name

- Select Options

> Save Test Setup As.

- Enter the new test setup name and click Save.

400G-TXE compliance measurements

DC common mode output voltage

This section verifies that the DC common mode output voltage of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| OIF-PAM4 | OIF-CEI-VSR, Table 16-10 | TP0a | -0.3 V | 2.8 V |

| OIF-CEI-VSR, Table 16-1 | TP1a | -0.3 V | 2.8 V | |

| OIF-CEI-VSR, Table 16-4 | TP4 | -0.35 V | 2.85 V | |

| OIF-CEI-MR, Table 17-2 | Testpoint-T | 0 V | 1.9 V | |

| OIF-CEI-LR, Table 21-2 | Testpoint-T | 0 V | 1.9 V | |

| IEEE-PAM4 |

AUI-IEEE802.3bs, Annex 120D.3.1 | TP0a | -0.3 V | 2.8 V |

| TP1a | -0.35 V | 2.85 V | ||

| TP4 | 0 V | 1.9 V | ||

|

CR4-IEEE802.3cd Section 136.9.3 | TP2 | 0 V | 1.9 V | |

|

KR4-IEEE802.3cd Section 137.9.2 | TP0a | 0 V | 1.9 V | |

| AUI-C2C. IEEE 802.3ck, Annex 120F.3.1, Table 120F-1 | TP0v | 0.2 V | 1 V | |

| AUI-C2M Host. IEEE 802.3ck Annex 120G.3.1, Table 120G-1 | TP1a | -0.3 V | 2.8 V | |

| AUI-C2M Module. IEEE 802.3ck Annex 120G.3.2, Table 120G-3 | TP4 | -0.35 V | 2.85 V | |

| CR. IEEE802.3ck Section 162.9.4, Table 162-11 | TP2 | NA | 1.9 V | |

Measurement procedure

Maximum input to be provided to the ATI channels is ≤ 300 mV peak-to-peak. The DC common mode voltage of the signal cannot be measured using ATI channels. Measure the voltage using an external digital multimeter and enter the value in the application.

AC Common Mode Output Voltage

This section verifies that the common mode noise of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| OIF-PAM4 | OIF-CEI-VSR, Table 16-10 | TP0a | NA | 12 mV |

| OIF-CEI-VSR, Table 16-1 | TP1a | NA | 17.5 mV | |

| OIF-CEI-VSR, Table 16-4 | TP4 | NA | 17.5 mV | |

| OIF-CEI-MR, Table 17-2 | Testpoint-T | NA | 30 mV | |

| OIF-CEI-LR, Table 21-2 | Testpoint-T | NA | 30 mV | |

| IEEE-PAM4 | AUI-IEEE802.3bs, Annex 120D.3.1 | TP0a | NA | 30 mV |

| TP1a | NA | 17.5 mV | ||

| TP4 | NA | 17.5 mV | ||

| CR4-IEEE802.3cd Section 136.9.3 | TP2 | NA | 30 mV | |

| KR4-IEEE802.3cd Section 137.9.2 | TP0a | NA | 30 mV | |

| AUI-C2C. IEEE 802.3ck, Annex 120F.3.1, Table 120F-1 | TP0v | 0.2 V | 1 V | |

Input

Positive and negative signals from the oscilloscope by setting the bandwidth to 40 GHz

Measurement procedure

The common mode voltage is a measure of the deviation of the common mode signal around the mean value. Find the sum of the positive and negative signals to create the common mode signal and create a vertical histogram on this signal. The RMS value of the vertical histogram is the AC common mode output voltage.

To find the effective common mode voltage after removing the instrumentation noise, use the following formula:

Single-ended output voltage

This section verifies that the single-ended output voltage of the data positive and data negative signals of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| OIF-PAM4 | OIF-CEI-MR, Table 17-2 | Testpoint-T | -0.3 V | 1.9 V |

| OIF-CEI-LR, Table 21-2 | Testpoint-T | -0.3 V | 1.9 V | |

| IEEE802.3bs | AUI-IEEE802.3bs, Annex 120D.3.1 | TP1a | -0.4 V | 3.3 V |

| IEEE 802.3ck | AUI-C2M Host. IEEE 802.3ck Annex 120G.3.1, Table 120G-1 | TP1a | -0.4 V | 3.3 V |

Input

Data positive and data negative signals

Measurement procedure

The single-ended output voltage is the measure of maximum and minimum values of the single-ended signals. Since the voltage levels can go beyond the 300 mV peak-to-peak, this measurement cannot be done using the ATI channels of the oscilloscope. Connect a DC block to eliminate the DC content present in the signal and then measure the maximum and minimum values of the positive and negative signals.

Effective Data Positive Max voltage = DC Common Mode + Data Positive Max

Effective Data Positive Max voltage = DC Common Mode + Data Positive Min

| Note:DC Common Mode measurement is pre-requisite for this measurement and you will be prompted to measure DC voltage using external multimeter.

|

Diff peak to peak output voltage Tx enabled

This section verifies that the differential peak-to-peak voltage of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| OIF-PAM4 | OIF-CEI-VSR, Table 16-10 | TP0a | 750 mV | NA |

| OIF-CEI-VSR, Table 16-1 | TP1a | NA | 880 mV | |

| OIF-CEI-VSR, Table 16-4 | TP4 | NA | 900 mV | |

| OIF-CEI-MR, Table 17-2 | Testpoint-T | NA | 1200 mV | |

| OIF-CEI-LR, Table 21-2 | Testpoint-T | NA | 1200 mV | |

| IEEE-PAM4 |

AUI-IEEE802.3bs, Annex 120D.3.1 | TP0a | NA | 1200 mV |

| TP1a | NA | 880 mV | ||

| TP4 | NA | 900 mV | ||

|

CR4-IEEE802.3cd Section 136.9.3 | TP2 | NA | 1200 mV | |

|

KR4-IEEE802.3cd Section 137.9.2 | TP0a | NA | 1200 mV | |

| AUI-C2C. IEEE 802.3ck Annex 120F.3.1, Table 120F-1 | TP0v | NA | 1200 mV | |

| AUI-C2M Host. IEEE 802.3ck Annex 120G.3.1, Table 120G-1 | TP1a | NA | 750 mV | |

| AUI-C2M Module. IEEE 802.3ck Annex 120G.3.2, Table 120G-3 | TP4 | NA |

| |

| CR.IEEE 802.3ck Section 162.9.2, Table 162-11 | TP2 | NA | 1200 mV | |

Input

QPRBS13-CEI or any valid signal filtered through a fourth order Bessel Thomson filter.

Measurement procedure

The differential peak-to-peak voltage is the peak-to-peak value of the signal acquired using a base oscilloscope.

Diff peak to peak output voltage Tx disabled

This section verifies that the differential peak-to-peak voltage of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| IEEE-PAM4 | AUI-IEEE802.3bs, Annex 120D.3.1 | TP1a | NA | 30 mV |

| TP0a | NA | 35 mV | ||

|

CR4-IEEE802.3cd Section 136.9.3 | TP2 | NA | 30 mV | |

|

KR4-IEEE802.3cd Section 137.9.2 | TP0a | NA | 30 mV | |

| AUI-C2C. IEEE 802.3ck, Annex 120F.3.1, Table 120F-1 | TP0v | NA | 35 mV | |

| AUI-C2M Host. IEEE 802.3ck, Annex 120G.3.1, Table 120G-1 | TP1a | NA | 35 mV | |

| CR.IEEE 802.3ck Section 162.9.2, Table 162-11 | TP2 | NA | 30 mV | |

Input

Noise signal captured when the DUT is disabled (without applying filters)

Measurement procedure

- Capture the differential noise using Math1 as source (without applying filters). Math1 = (Data positive – Data negative)

Note:For IEEE 802.3ck, Capture the differential noise using Math1 as Source , Math1 = Arnflt1 (Data positive – Data negative), Arbflt1 – Bessel Thomson Filter

Note:For IEEE 802.3ck, Capture the differential noise using Math1 as Source , Math1 = Arnflt1 (Data positive – Data negative), Arbflt1 – Bessel Thomson Filter - Select the oscilloscope free run mode option.

- In oscilloscopes menu, select and select peak-to-peak measurement.

- Value of Peak-Peak measurement is reported as the differential peak-to-peak output voltage.

Transition time

This section verifies that the transition time of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| OIF-PAM4 | OIF-CEI-VSR, Table 16-10 | TP0a | 7.5 ps | NA |

| OIF-CEI-VSR, Table 16-1 | TP1a | 12 ps | NA | |

| OIF-CEI-VSR, Table 16-4 | TP4 | 9.5 ps | NA | |

| IEEE802.3bs | AUI-IEEE802.3bs, Annex 120D.3.1 | TP1a | 10 ps | NA |

| AUI-IEEE802.3bs, Annex 120D.3.1 | TP4 | 9.5 ps | NA | |

| IEEE 802.3ck | AUI-C2M Host. Annex 120G.3.1, Table 120G-1 | TP1a |

| NA |

| AUI-C2M Module. Annex 120G.3.2, Table 120G-3 | TP4 | 8.5 ps | NA | |

Input

QPRBS13-CEI test pattern or any valid signal filtered through a fourth order Bessel Thomson filter.

Measurement procedure

Transition time (rise and fall) are defined as the time between the 20% and 80% times, or 80% and 20% times, respectively, of isolated -1 to +1 or +1 to -1 PAM4 edges. Using the QPRBS13-CEI test pattern, the transitions within sequences of three -1s followed by three +1s, and three +1s followed by three -1s, respectively, are measured. These are PAM4 symbols 1820 to 1825 and 2086 to 2091, respectively, where symbols 1 to 7 are the run of seven +1’s. In this case, the 0% level and 100% level may be estimated as the average signal within windows from -1.5 UI to -1 UI and from 1.5 UI to 2 UI relative to the edge.

TekExpress 400G-TXE application captures sufficient record length and uses PAM4 utility to perform this measurement.

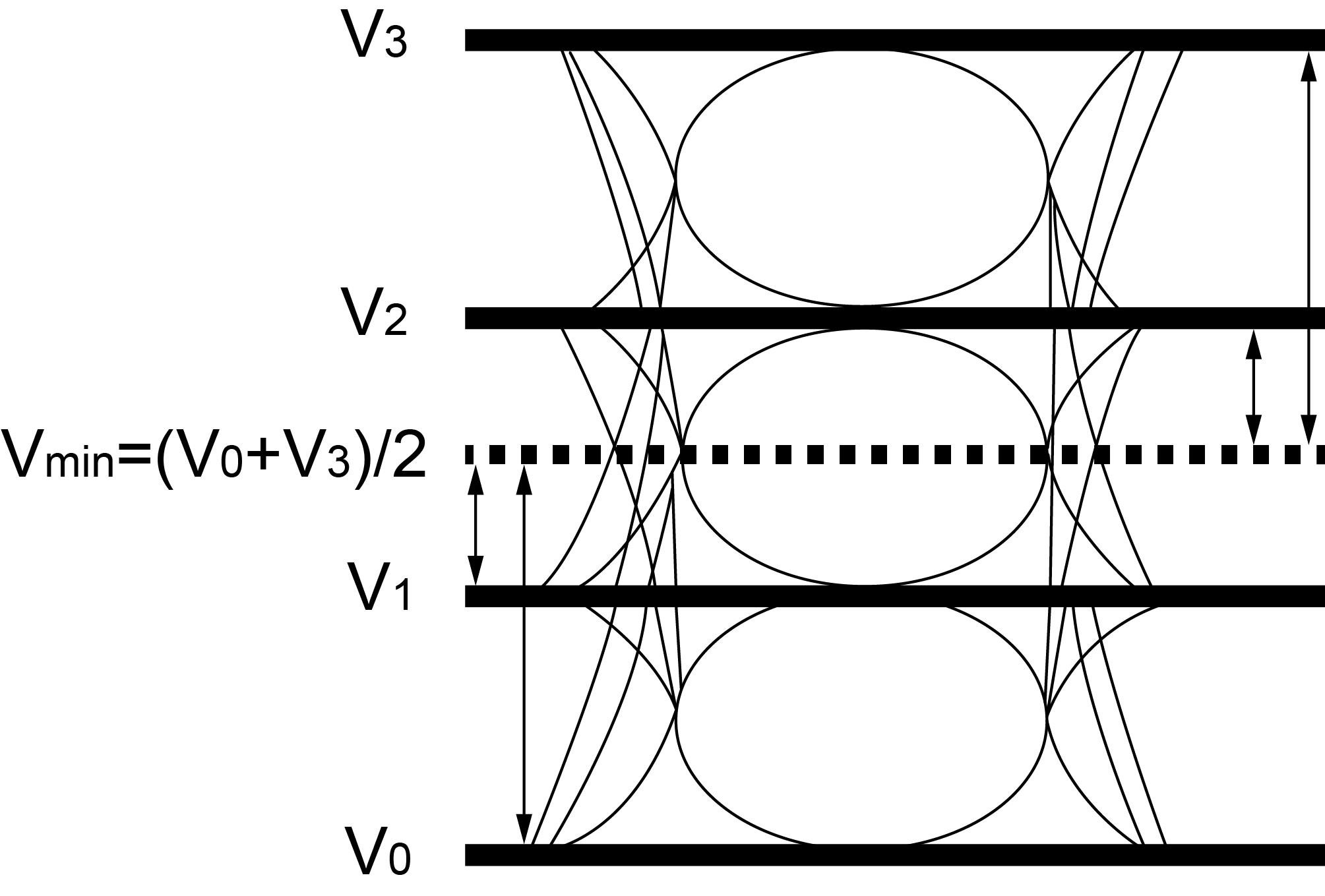

Eye width, VEC (Vertical Eye Closure), Eye height, Eye linearity, and Eye symmetry mask width

This section verifies that the Eye width, VEC (Vertical Eye Closure), Eye height, Eye linearity, and Eye symmetry mask width of the DUT are within the conformable limits according to the specification.

Required test equipment

| Standard | Measurement | Specification | Test Points | Limits | |

|---|---|---|---|---|---|

| Min | Max | ||||

| OIF-PAM4 | Eye Width | OIF-CEI-VSR, Table 16-1 | TP1a | 0.2 UI | NA |

| Eye Height | 35 mV | NA | |||

| Eye Linearity | 0.85 | NA | |||

| Eye Symmetry Mask Width | EW6 | NA | |||

| Near End Eye Width | OIF-CEI-VSR, Table 16-4 | TP4 | 0.265 UI | NA | |

| Near End Eye Height | 70 mV | NA | |||

| Near End Eye Linearity | 0.85 | NA | |||

| Far End Eye Width | 0.2 UI | NA | |||

| Far End Eye Height | 70 mV | NA | |||

| Eye Symmetry Mask Width | EW6 | NA | |||

| IEEE-PAM4 | Eye Symmetry Mask Width | AUI-IEEE802.3bs | TP1a | 0.2 UI | NA |

| Eye Height | 32 mV | NA | |||

| Near End Eye Symmetry Mask Width | AUI-IEEE802.3bs | TP4 | 0.265 UI | NA | |

| Near End Eye Height | 70 mV | NA | |||

| Far End Eye Symmetry Mask Width | 0.2 UI | NA | |||

| Far End Eye Height | 30 mV | NA | |||

| Eye height | AUI-C2M Host. IEEE 802.3ck Annex 120G.3.1, Table 120G-1 | TP1a | 10 mV | NA | |

| Vertical Eye closure | NA | 12 dB | |||

| Near end Eye height | AUI-C2M Module. IEEE 802.3ck Annex 120G.3.2, Table 120G-3 | TP4 | 15 mV | NA | |

| Far end Eye height | |||||

| Near end Vertical Eye closure | NA | 12 dB | |||

| Far end Vertical Eye closure | |||||

Input

Differential signal filtered through fourth order Bessel Thomson filter (with appropriate bandwidth) in concatenation with a Continuous Time Linear Equalizer (CTLE).

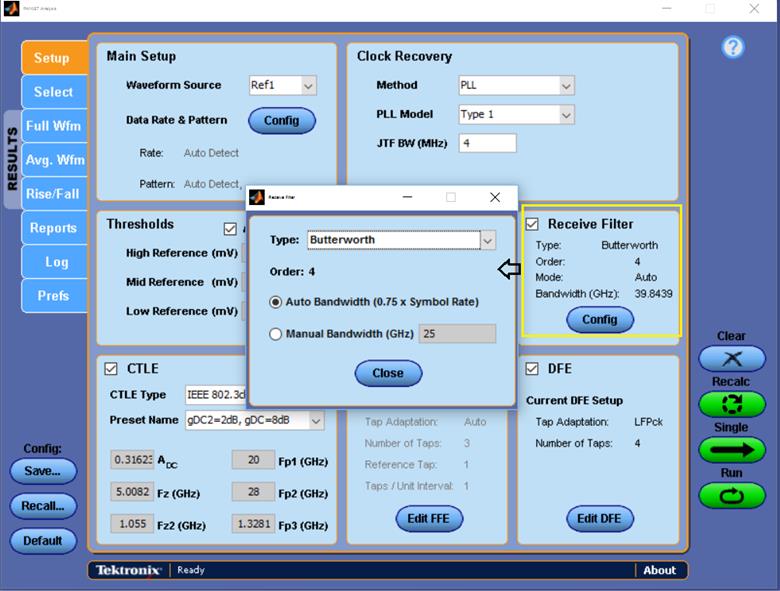

In case of AUI-IEEE802.ck, The Eye-opening parameters Eye height and VEC are measured with the effect of a reference receiver (Butterworth filter) which includes receiver input referred noise, a continuous-time filter and DFE (4th Order) as per the specification.

Cross talk calibration

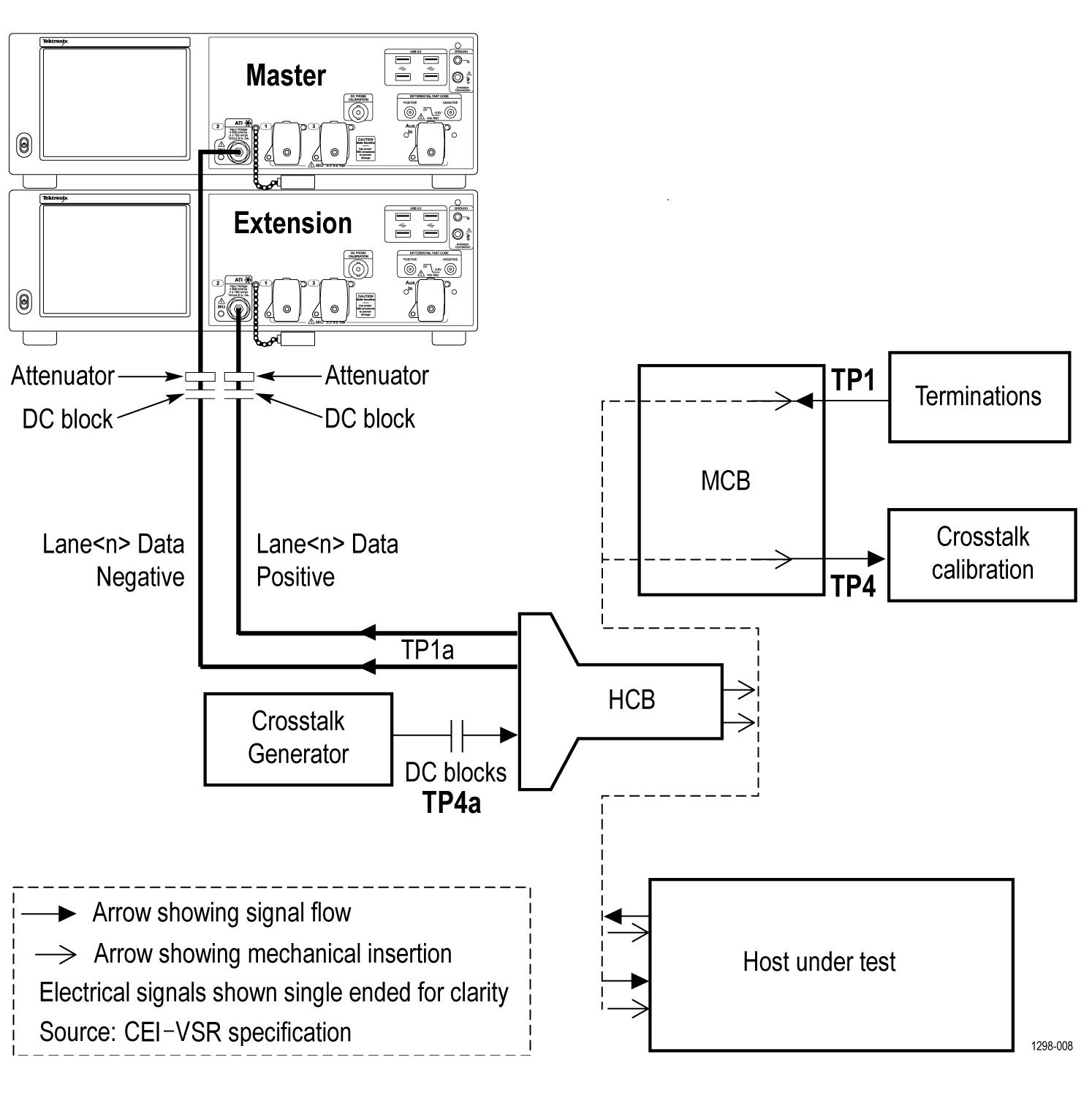

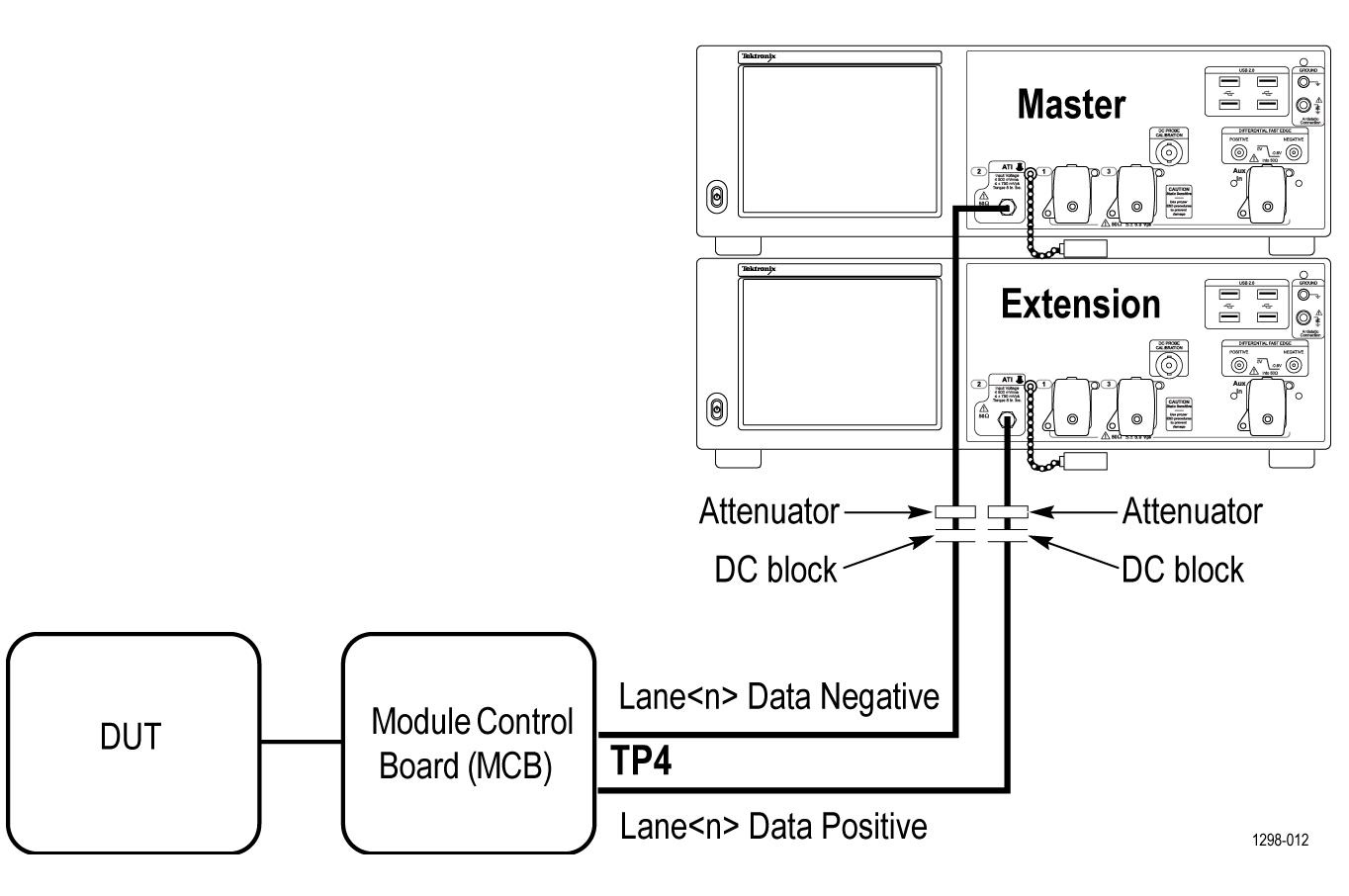

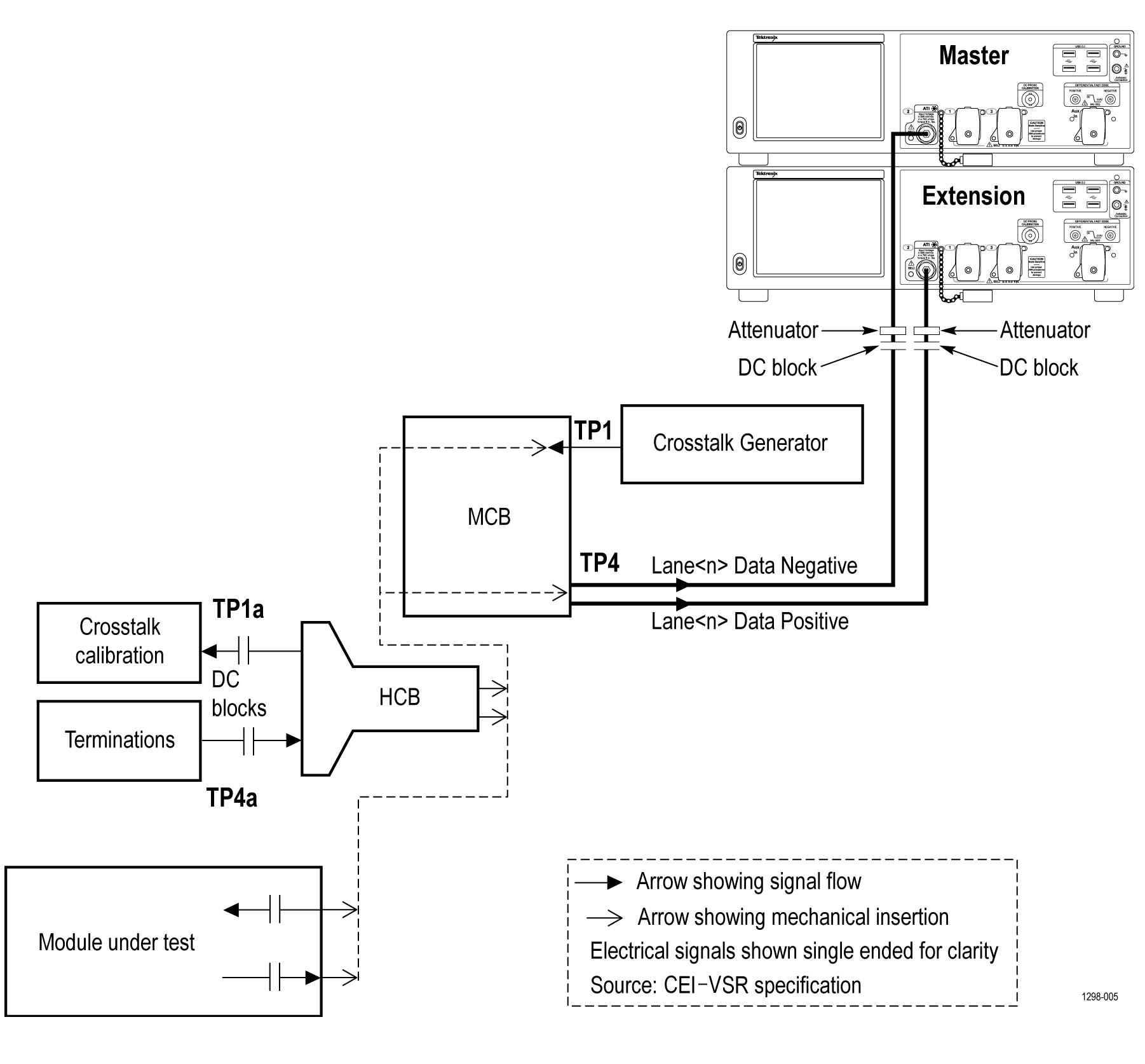

Calibrate the co-propagating signals (signal on the other lanes) as per the specification, before performing the Eye measurements.

If you want to run with cross talk source, select Crosstalk Source from the DUT panel. By default, this option is unselected and application will provide normal connection diagram procedure.

Eye measurements are done after passing the signal through a reference receiver which includes a fourth order Bessel Thomson filter (in case of IEEE802.3ck Eye measurement, receiver Butterworth filter is used) with appropriate bandwidth cutoff and a selectable continuous time linear equalizer (CTLE filter). It is recommended to use PRBS13Q pattern for this measurement.

| Note:For 112G-VSR Eye measurements, signal will be passed through additional five tap FFE equalizer after Bessel Thomson and CTLE filters |

CTLE filters are selected as per the below table:

| Specification | Test point | CTLE filters |

|---|---|---|

|

CEI-56G-VSR |

At Host output TP1a |

1 dB - 9 dB |

|

At Module output TP4 (Near End) |

1 dB - 2 dB | |

|

At CEI-VSR Module output TP4 (Far End) |

1 dB - 9 dB | |

|

CEI-112G-VSR |

At Host output TP1a, TP4 |

1 dB - 13 dB |

|

200/400GAUI-4/8 |

At Host output TP1a |

1 dB - 9 dB |

|

At Module output TP4 (Near End) |

1 dB - 3 dB | |

|

At Module output TP4 (Near End) |

1 dB - 9 dB |

| Parameter | Symbol | Value(dB) |

|---|---|---|

| Continuous time filter, DC gain for TP1a | ||

| Range for gDC2 = 0 | gDC | –2 to –9 |

| Range for –1 ≤ gDC2 < 0 | –2 to –11 | |

| Range for –2 ≤ gDC2 < –1 | –4 to –10 | |

| Range for –3 ≤ gDC2 < –2 | –4 to –9 | |

| Step size | 1.0 | |

| Continuous time filter, DC gain 2 for TP1a | ||

| Range | gDC2 | –3 to 0 |

| Step size | 0.5 | |

| Continuous time filter, DC gain for TP4 near-end | ||

| Range | gDC | –5 to –1 |

| Step size | 1.0 | |

| Continuous time filter, DC gain 2 for TP4 near-end | ||

| Range | gDC2 | –2 to 0 |

| Step size | 0.5 | |

| Continuous time filter, DC gain for TP4 far-end | ||

| Range | gDC | –9 to –2 |

| Step size | 1.0 | |

| Continuous time filter, DC gain 2 for TP4 far-end | ||

| Range | gDC2 | –3 to –1 |

| Step size | 0.5 | |

TekExpress uses PAM4/PAMJET utility to perform this measurement. Details about measuring Eye width and Eye height from the equalized signal is explained in OIF-CEI-56G-VSR and IEEE802.3bs specifications.

- Near End Eye measurements

- Far End Eye measurements

Near End Eye width, VEC and Eye height are same as Eye width and Eye height measurements. Whereas far end Eye width and Eye height measurements are done with an emulated loss channel.

- Best CTLE filter is the one which gives maximum Eye area (EW*EH) and it passes corresponding Eye parameters.

- In case of OIF standard, best CTLE filter is the one which gives passing result for Eye width, Eye height and Eye linearity.

- In case of IEEE standard, best CTLE filter is the one which gives maximum Margin from Limit for VEC and EH

- Rapid

- Exhaustive

Rapid approach finds the optimized and faster way to reach to best CTLE. Where exhaustive simply run each CTLE form list of individual and get the Best out of it. User can go the configuration tab and check the Best CTLE to run for next run.

| Note:Eye measurement for IEEE802.3ck also use the below configuration as per specification. |

- Acquire the signal (record length depends on the symbol rate).

- Calculate Eye measurements (Eye width, Eye height and Eye linearity if required) for all CTLE filters at BER of 1e-5.

- Calculate the Eye Area (EW*EH), select the CTLE with maximum Eye area and passing Eye parameter limits of spec as reference CTLE filter for analysis.

- Use the reference filter and measure the Eye parameters configured at BER as per specification (By default for OIF:1e-6 and for IEEE:1e-5 BER is used).

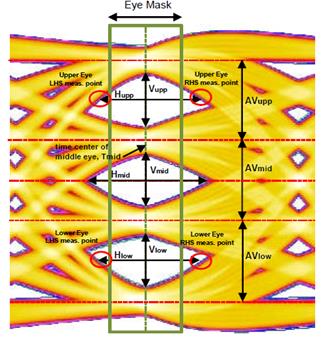

Eye symmetry mask width (ESMW)

An Eye mask of width as per the specification is drawn on the top of Eye diagram. All the three Eyes have to open beyond the mask drawn which will make the test pass.

- Use the reference CTLE filter for analysis. Horizontal mid-point of Eye diagram (Tmid) is queried from the PAM4 utility.

- Mask width has to be read from UI.

- Mask_Left = Tmid - Mask_Width/2 and Mask_Right = Tmid + Mask_Width/2

- Test is pass if all 3 Eyes extend beyond the Eye width mask, else test is fail.

- Query Hupp_Left and Hupp_Right values from the PAM4 utility which correspond to the left and right Eye boundaries for Upper Eye.

- If (Mask_left>=Hupp_Left and Mask_Right<=Hupp_Right) then pass, otherwise fail

- Repeat steps 5 and 6 for middle and Lower Eyes. For middle eye, query Hmid_Left and Hmid_Right. Also for Lower Eye, query Hlow_left and Hlow_right

Signal-to-noise and distortion ratio

This section verifies that the signal-to-noise and distortion ratio (SNDR) of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| OIF-PAM4 | OIF-CEI-VSR, Table 16-10 | TP0a | 31 dB | NA |

| OIF-CEI-MR, Table 17-2 | Testpoint-T | 31 dB | NA | |

| OIF-CEI-LR, Table 21-2 | Testpoint-T | 31 dB | NA | |

| IEEE-PAM4 |

AUI-IEEE802.3bs, Annex 120D.3.1 | TP0a | 31 dB | NA |

|

CR4-IEEE802.3cd Section 136.9.3 | TP2 | 33.3 dB | NA | |

|

KR4-IEEE802.3cd Section 137.9.2 | TP0a | 32.5 dB | NA | |

| AUI-C2C. IEE 802.3ck, Annex 120F.3.1, Table 120F-1 | TP0v | 32.5 dB | NA | |

| CR. IEEE 802.3ck Section 162.9.4, Table 162-11 | TP2 | 31.5 dB | NA | |

Input

Differential signal filtered through a fourth order Bessel Thomson filter with appropriate bandwidth

Measurement procedure

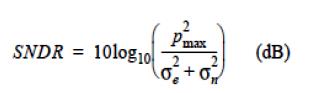

Signal-to-noise and distortion ratio is measured using the following formula:

Where,

Pmax is the linear fit pulse peak

σe - RMS error

σn – Standard deviation of noise

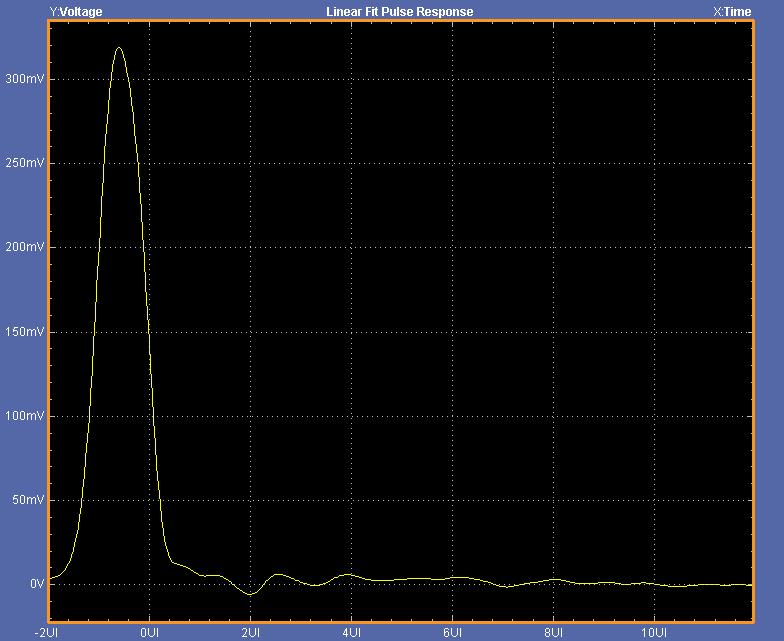

Pre-cursor and post-cursor equalization ratio

This section verifies that the pre-cursor and post-cursor equalization ratio of the Device Under Test (DUT) is within conformance limits as given in IEEE802.3 200GAUI-4/400GAUI-8 specification at test point TP0a, Table 120D-1, Section 120D.3.1.5.

Required test equipment

| Standard | Specification | Test Points |

|---|---|---|

| IEEE-PAM4 |

AUI-IEEE802.3bs, Annex 120D.3.1 | TP0a |

Measurement procedure

- Set the DUT in PRESET state and find the Linear fit pulse response.

- For pre-cursor test, prompt the user to vary the Local_eq_cm1 value from 0 to 3 and each time find the equalizer coefficients C(-1), C(0) and C(1) value using PRESET linear fit curve and linear fit of each state of Local_eq_cm1.

- Find the pre-cursor equalization ratio using below formula:

- Vary the Local_eq_c1 value from 0 to 5 and each time find the equalizer coefficients C(-1), C(0) and C(1) value using PRESET Linear fit curve and Linear fit of each state of Local_eq_c1.

- Find the Post-cursor equalization ratio using below formula:

Limits

Pre-cursor equalization ratio for each state of Local_eq_cm1 are the following:

| Local_eq_cm1 value |

|

|---|---|

| 0 | 0±0.04 |

| 1 | -0.05±0.04 |

| 2 | -0.1±0.04 |

| 3 | -0.15±0.04 |

Pre-cursor equalization ratio for each state of Local_eq_c1 are the following:

| Local_eq_c1 value |

|

|---|---|

| 0 | 0±0.04 |

| 1 | -0.05±0.04 |

| 2 | -0.1±0.04 |

| 3 | -0.15±0.04 |

| 4 | -0.2±0.04 |

| 5 | -0.25±0.04 |

Coefficient range (OIF)

This section verifies that the coefficient range of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | ||

|---|---|---|---|---|---|

| Min | Max | ||||

| OIF-PAM4 | OIF-CEI-MR, Table 17-2 | Testpoint-T | C(-1) | -15% | 0% |

| C(0) | 60% | 100% | |||

| C(1) | -25% | 0% | |||

| OIF-CEI-LR, Table 21-2 | Testpoint-T | C(-2) | 0% | 10% | |

| C(-1) | -28% | 0% | |||

| C(0) | 60% | 100% | |||

| C(1) | -28% | 0% | |||

Measurement procedure

- Acquire the PRESET signal. Export the linear fit impulse response curve from PAM4 utility.

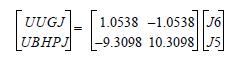

-

Increment a coefficient (C(-2), C(-1), C(0) or C(1)) such that it reaches its maximum value and keep all other coefficients in hold state. Export the Linear fit impulse response from PAM4 utility .

- Find the equalizer coefficients using PRESET and incremented linear fit pulses.

-

Similarly ask the user to sufficiently decrement the equalizer coefficient (C(-1), C(0) and C(1)) one by one such that it reaches its minimum value. Capture the waveform and find the linear fit pulse from the PAM4 utility .

-

Find the equalizer coefficients using PRESET and decremented linear fit pulses.

- Verify that each transmitter equalizer coefficient is within the minimum and maximum range of specification.

Increment each coefficient individually to reach its maximum value. You must reconfigure the coefficient to its original value before incrementing another coefficient.

Coefficient range (IEEE)

This section verifies that the coefficient range of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | ||

|---|---|---|---|---|---|

| Min | Max | ||||

| IEEE-PAM4 |

CR4-IEEE802.3cd Section 136.9.3 | TP2 | C(-2) | 0.1 | NA |

| C(-1) | NA | -0.25 | |||

| C(1) | NA | -0.25 | |||

|

KR4-IEEE802.3cd Section 137.9.2 | TP0a | C(-2) | 0.1 | NA | |

| C(-1) | NA | -0.25 | |||

| C(1) | NA | -0.25 | |||

| AUI-C2C. IEEE 802.3ck, Annex 120F.3.1, Table 120F-1 | TP0v | C(-3) decrement | NA | =<-0.05 | |

| C(-3) increment | 0>= | NA | |||

| C(-2) decrement | NA | <=0.0 | |||

| C(-2) increment | >=0.1 | NA | |||

| C(-1) decrement | NA | <=-0.3 | |||

| C(-1) increment | >=0.0 | NA | |||

| C(0) decrement | NA | =<0.5 | |||

| C(1) decrement | NA | =<-0.1 | |||

| C(1) increment | >=0.0 | NA | |||

| CR.IEEE 802.3ck Section 162.9, Table 162-11 | TP2 | C(-3) decrement | NA | <= - 0.06 | |

| C(-2) decrement | >= 0.12 | NA | |||

| C(-1) decrement | NA | <= - 0.34 | |||

| C(0) decrement | NA | <= - 0.5 | |||

| C(1) decrement | NA | <= - 0.2 | |||

Measurement procedure

- Range for C(1) or value at minimum state for C(1): with C(-2) and C(-1) both set to zero and both C(0) and C(1) having received sufficient “decrement” requests so that they are at their respective minimum values, C(1) shall be less than or equal to -0.25

- Range for C(-1) or value at minimum state for C(-1): with C(-2) and C(1) set to zero and both C(-1) and C(0) having received sufficient “decrement” requests so that they are at their respective minimum values, C(-1) shall be less than or equal to -0.25

- Range for C(-2) or value at maximum state for C(-2): with C(-1) and C(1) set to zero, C(0) having received sufficient “decrement” requests so that it is at its minimum value, and C(-2) having received sufficient “increment” requests so that it is at its maximum value, C(-2) shall be greater than or equal to 0.1

Measurement procedure for IEEE 802.3ck

- Range for C(1) or value at minimum state for C(1): With C(-3), C(-2), and C(-1) set to zero and both C(0) and C(1) having received sufficient "increment" or “decrement” requests so that they are at their respective maximum or minimum values.

- Range for C(0) or value at minimum state for C(0): With C(-3), C(-2), C(-1), and C(1) set to zero and having received sufficient “decrement” requests so that it is at its minimum value.

- Range for C(-1) or value at minimum state for C(-1): with C(-3), C(-2), and C(1) set to zero and both C(-1) and C(0) having received sufficient "increment" or “decrement” requests so that they are at their respective maximum or minimum values.

- Range for C(-2) or value at maximum state for C(-2): With C(-3), C(-1), and C(1) set to zero, C(0) having received sufficient "increment" or "decrement" requests so that it is at its maximum value, and C(-2) having received sufficient "increment" or "decrement" requests so that it is at its maximum or minimum value.

- Range for C(-3) or value at minimum state for C(-3): With C(-2), C(-1), and C(1) set to zero and both C(-3) and C(0) having received sufficient "increment" or “decrement” requests so that they are at their respective maximum or minimum values.

Far end pre-cursor ISI ratio

This section verifies that the far end pre-cursor ISI ratio of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | ||

|---|---|---|---|---|---|

| Min | Max | ||||

| IEEE-PAM4 |

CR4-IEEE802.3cd Section 136.9.3 | TP2 | C(-2) | 0.1 | NA |

| C(-1) | NA | -0.25 | |||

| C(1) | NA | -0.25 | |||

|

KR4-IEEE802.3cd Section 137.9.2 | TP0a | C(-2) | 0.1 | NA | |

| C(-1) | NA | -0.25 | |||

| C(1) | NA | -0.25 | |||

Measurement procedure

- Apply the CTLE filter which produces the optimal eye opening and export the linear fit pulse from the PAM4 utility.

- Using linear fit impulse, measure the far end pre-cursor ratio:

Far End Pre-cursor ratio = Ppre/Pmax

Where,

Ppre is the value of linear fit pulse 1 UI prior to the time of the pulse peak

Pmax is the peak amplitude of the linear fit pulse

Transmitter output residual ISI

This section verifies that the maximum value of transmitter output residual ISI of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points | Limits | |

|---|---|---|---|---|

| Min | Max | |||

| IEEE-PAM4 |

AUI-IEEE802.3bs, Annex 120D.3.1 | TP0a | 34.8 dB | NA |

Measurement procedure

- Acquire the signal and export the linear fit pulse using PAM4 utility.

- Perform single sequence in PAM4 utility and export the linear fit pulse to a file.

- Using Linear fit pulse, calculate the SNR-ISI value using below equation:

ISI cursors are calculated using below equation:

Where,

tp is the index of the linear fit pulse where p(tp) = pmax

M is the oversampling ratio of the measured waveform and linear fit pulse

Np is the linear fit pulse length

Nb is given in Table 120D–8

For UAI-4 at TP0a, Equalization has to be performed on signal before running measurement for SNR-ISI. For CR4 and KR4, measurement is done on unequalized signal.

Equalization procedure

| gDC | gDC2 | G | ZLF | Z1 | PLF | P1 | P2 |

| -15 to 0 | -4 to 0 | 1 |

|

| fb/40 | fb/2.5 | fb*2 |

-

Equalize the signal with equalization filters given above(varying gDC and gDC2) ad measure the SNR-ISI in each case

- Maximum value of SNR-ISI is reported out as result.

| Note:The observed SNRISI can be significantly influenced by the measurement setup, for example, the reflections in cables and connectors. High-precision measurement and careful calibration of the setup are recommended.

|

Normalized coefficients step size

This section verifies that the normalized coefficients step size of the DUT is within the conformable limits according to the specification.

Required test equipment

| Standard | Specification | Test Points |

|---|---|---|

| OIF-PAM4 | CEI-MR | T |

| CEI-LR | T | |

| IEEE-PAM4 |

CR4-IEEE802.3cd, Section 136.9.3 | TP2 |

|

KR4-IEEE802.3cd, Section 137.9.2 | TP0a | |

| AUI- IEEE802.3ck, Section 120F.3.1, Table 120F-1 | TP0v |

Measurement procedure

Normalized coefficient step size is the measure of variation in the equalizer coefficient when the increment or decrement operations were done.

- Set the DUT in PRESET state. Export the linear fit pulse response from PAM4 utility.

- Set the DUT in INITIALIZE state. Export the Linear fit pulse response from PAM4 utility.

- Calculate all the equalizer coefficient C(x) before using these linear fit pulse responses and denote it as C(x)_Before.

- Increment or decrement the equalizer coefficient in DUT by giving an increment or decrement command.

- Measure the linear fit pulse response. Calculate the updated equalizer coefficient C(x) in the signal using linear fit pulse response before and after sending increment or decrement request and denote it as C(x)_After.

-

Find the Increment or decrement step size for equalizer coefficient C(x) using below equation.

Increment or decrement step size = C(x)_After – C(x)_Before

Normalized coefficient step size for C(x) is calculated using below equation:

Normalized coefficient step size = Absolute value of ((Increment or Decrement step size) / C(x)_Before)*100

-

Repeat the above method for all the coefficients to find the increment and decrement step sizes.

Limits