Precision Matters: The Critical Role of Calibration in High-Performance Electronics

Calibration is the cornerstone of precision and reliability in high-performance electronic test equipment. Unlike mechanical or dimensional calibrations which are based on physical disciplines, calibrating advanced electronic systems requires extensive electrical circuitry understanding. In high-speed systems, errors—like a ±2.00 dB deviation—can lead to critical issues such as signal noise, jitter, attenuation, or crosstalk. These inaccuracies can result in costly mistakes, from accepting faulty designs to rejecting functional ones.

Proper calibration ensures engineers and scientists can trust their measurements, enabling accurate, repeatable, and reliable testing. It upholds compliance with industry standards, builds consistency across instruments and environments, and ultimately supports informed decision-making.

Here’s why calibration matters:

- Scientific Integrity: Trustworthy results are foundational to credibility. Miscalibration undermines data reliability and reputations.

- Accuracy in Measurement: Small deviations can lead to incorrect conclusions during design validation or troubleshooting.

- Consistency and Repeatability: Calibrated instruments deliver reliable results across facilities, essential for industries like aerospace, telecommunications, and medical devices.

- Product Quality and Reliability: Accurate testing ensures only functional, high-quality products reach the market, reducing costly errors.

- Compliance with Standards: Calibration supports adherence to stringent industry standards such as ISO/IEC 17025, AS9100, and FDA 21 CFR Part 820.

- Cost Efficiency: Early detection of issues prevents expensive failures, warranty claims, and rework, ultimately protecting reputation and resources.

Calibration is not merely a technical necessity—it’s a strategic investment in product quality, operational reliability, and customer satisfaction.

Practical Implications Example: The Impact of RF Miscalibration at 250 MHz

Imagine you're using a function generator to produce a 2V peak-to-peak 250 MHz square wave RF signal for testing a wireless communication system, corresponding to 10dBm of power level into 50 ohm. The system requires precise output power level and frequency accuracy and stability to ensure proper signal reception.

Now, consider this scenario: the generator is miscalibrated, outputting a signal that is half dB off instead of staying within the allowable ±0.4dB tolerance.

Here’s what could go wrong:

- Amplitude Error:

The receiver may misinterpret the signal strength, causing errors during data transmission, especially in presence of external attenuators or cables. This could result in failed communication links. - Phase Instability and Frequency Drift:

Even minor amplitude inaccuracies can affectphase stability, introducing frequency offsets that disrupt the synchronization between transmitter and receiver. This can lead to a cascading effect, degrading overall system performance. - Customer Impact:

If this issue goes undetdected and the system is deployed, end-users might experience dropped calls, slow data rates, or poor signal quality. This not only impacts customer satisfaction but also harms the reputation of the product and the company behind it.

This example underscores the critical role of calibration in ensuring reliable performance. With consistent, recurring calibration, engineers can trust their instruments to deliver accurate measurements, enabling the successful development, testing, and deployment of cutting-edge systems.

How is Calibration Performed on High Performance Electronic Equipment?

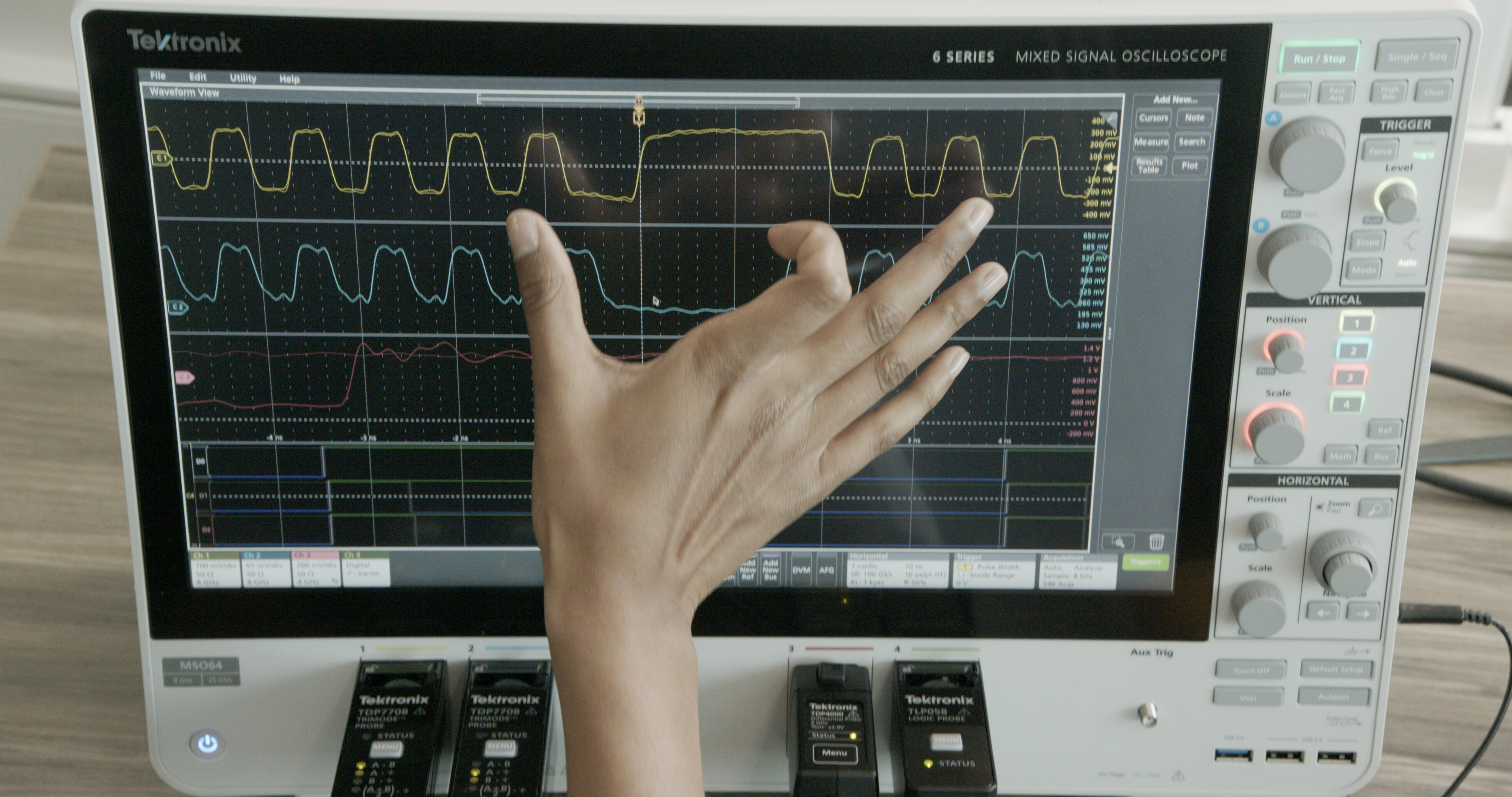

Calibration of high-performance electronic test equipment at Tektronix is an automated process that ensures measurement accuracy and reliability. This involves rigorous testing of key parameters to meet the strict tolerances required for advanced electronic systems, which demands significant investment in expertise and specialized equipment.

Manufacturers, like Tektronix, provide detailed specifications and performance verification documents that outline essential performance attributes and tolerances. These serve as crucial references for ensuring compliance with industry standards. Other companies may have similar documents, such as "Performance Test Manuals," and they share the same goal: to detail tolerances and methodologies.

Tektronix calibration laboratories automate the testing of specifications to ensure consistency across all our calibration facilities, enabling engineers and scientists to make informed decisions based on dependable data. The process also simulates performance verification under real-world conditions. Detailed documentation provides traceability to recognized standards, ensuring compliance and confidence in accuracy.

Conclusion

Calibration is more than just a maintenance task—it is the backbone of accurate and reliable testing in high-performance electronic systems. Whether it's identifying subtle issues like signal jitter or ensuring compliance with industry standards, calibration enables engineers and scientists to make informed decisions with confidence.

By understanding the importance of calibration, investing in high-quality processes, and leveraging tools like Specification and Performance Verification documents, organizations can ensure their equipment operates at peak precision. This not only enhances product quality but also minimizes risks, reduces costs, and builds trust with customers.

As demonstrated by real-world examples, even slight deviations can lead to significant consequences, affecting system performance and customer satisfaction. Calibration mitigates these risks, ensuring measurements are accurate, repeatable, and trustworthy.

In an era of rapid technological advancements, calibration remains a critical practice that supports innovation, safeguards reliability, and drives success in product development and manufacturing. It’s not just about maintaining instruments—it’s about enabling excellence in every test, every result, and every product delivered.

Learn More About Tektronix Calibration Services

At Tektronix, we offer comprehensive calibration services to ensure your measurement instruments are always accurate and reliable. Learn more about how our calibration services can benefit your business