In 75 years of innovation, one thing still unites every aspect of technology from a cell phone to a space shuttle. Batteries.

At the forefront of testing those power supplies we all depend on has been the team of engineers at Keithley Instruments, a Tektronix company based in Solon, Ohio. Just outside of Cleveland, Keithley has had an outsized impact on the world of technology dating back to 1946.

“Mobile, EV, the infotainment we digest on a daily basis, we have a play in each and every one of these,” says Chris Bohn, Keithley’s general manager and recently named vice president of sales for parent company Tektronix.

In recent years the Keithley and Tektronix team has taken critical battery test to completely new levels, allowing engineers to help create breakthroughs in battery life once seemed unthinkable in the amount of power, longevity and efficiency.

The Cleveland Start

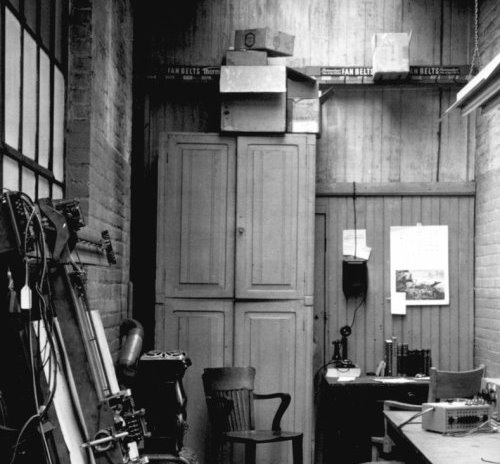

It’s all a far cry from the company’s humble origins in a leaky workshop Joseph F. Keithley rented in Cleveland for $8.50 per month. (At $110 in today’s dollars, it still would be a bargain).

A graduate of MIT with experience from Washington’s Naval Ordinance Lab, Joseph F. Keithley could have taken his engineering talents just about anywhere post World War II, but he went home to Cleveland, stayed, and made a world of difference.

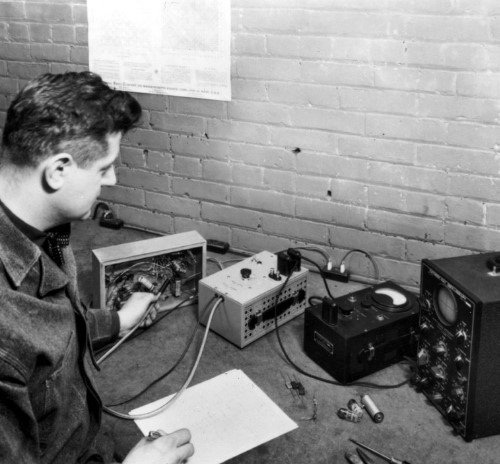

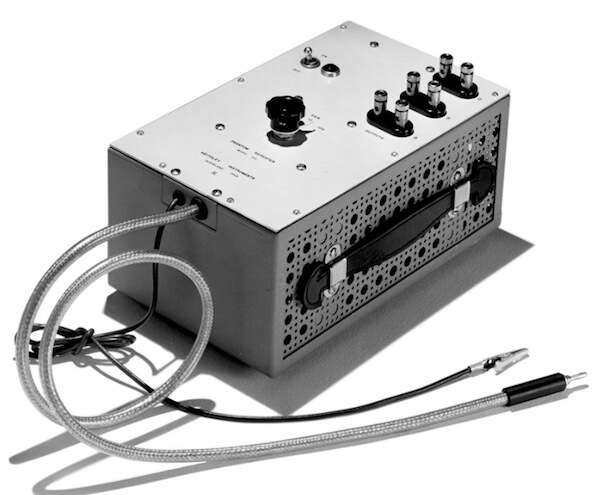

“I felt that the world needed a good amplifier,” Keithley once said. The Phantom Repeater could take a low-level circuit and increase it to be handled by oscilloscopes and voltmeters then in general use. The Phantom Repeater would be the beginning of a company devoted to engineering the future of test and measurement.

In the spring of 1950, Dr. Walter Michels, a physics professor, and friend of Keithley’s, suggested building an electrometer voltmeter, which would extend the Phantom Repeater’s high input impedance approach to DC voltmeters. The result was the Model 200, the first of a long line of Keithley electrometers, and a decade of growth that would set up the company to play an historic role in US space exploration.

The Early Tech Boom

The Soviet Union’s launch of Sputnik I in 1957 sent the space race itself into high orbit. In response, an aerospace group emerged at Keithley during the early 1960s to provide sensitive measurement systems for the American space program and support many early US satellite programs. Always looking toward the next big need, the innovative space team at Keithley shifted in the 1970s to lead the way on medical technology. The Radiation Control Act of 1968 had created more strict controls over x-ray and radiation-producing equipment, and Keithley’s expertise was ready to answer that call.

Similarly, as the world of computing grew, Keithley applied its expertise in low-level measurement to semiconductor testing, work which continues today.

But all along there has been an obsession with electric power. Ever smaller computers performing ever more demanding tasks created new demand for Keithley’s battery expertise.

The ability to characterize battery performance accurately became a significant concern for Keithley when it developed a line of handheld digital multimeters (DMMs) and temperature measurement instruments powered by standard 9V zinc-oxide batteries. Mark Hoersten, who joined the company in 1980 and helped design those instruments, recalls the company’s focus in those days.

“Battery life was an important part of our product offering. We spent a lot of time evaluating different vendors’ batteries, based on the load characteristics required,” says Hoersten, who became Keithley’s vice president of marketing and product planning. “Our tests involved draining the various batteries in much the same way as our handheld instruments would, which allowed us to select the ones that offered the longest life.”

By the 1980s, the personal and home computer was on the rise and Keithley’s business focused on creating programmable, computer-interfaceable instruments. This was the era that brought about the Models 236 and 237 Source Measure Units, the first of several generations of SMU instruments that Keithley would develop to address a broad range of applications, including battery test.

These innovations changed the test and measurement community. "Suddenly, they could say, ‘Okay, I want to know how long it lasts with a 100-milliamp, 12-volt load on it’ or any other current and voltage combination,” Hoersten says.

Keithley products and technology may have been the company’s most famous calling card, but it was the company’s culture that made its own indelible mark on its customers and the community at large.

Joseph Keithley said he wanted to be “famous for Quality, Service, Innovation and Integrity,” so much so that his car’s license plate read “QSII.” He built rewards for employees who helped improve the company and invested back in the community through hiring, investments in education, and record-breaking philanthropy.

Have Tech, Will Travel

As mobile design boomed and designers sought to create phones with longer battery life, Keithley worked closely with customers to create new tests to stay in front of the market.

“Battery life is not just a matter of convenience,” says Bohn. “You’ve got to charge that. That has a big chain effect on energy we use.”

That focus on helping customers maximize their power efficiency of their products continues today. “Everyone is trying to make more efficient use of power. Those boundaries are constantly being tested and we are at the forefront of both the high end and low end of testing those devices,” says Bohn.

In 2002, Keithley released its Model 2800 RF Power Analyzer, engineered specifically for high-speed testing of wireless phones and RF devices (everything from keycards to garage door openers).

Global Connection, Local Leadership

In 2010, Keithley became an indirect wholly owned subsidiary of Danaher Corporation, merged with Tektronix and shifted manufacturing to Tektronix facilities. As part of the Fortive family of companies today, Keithley continues to be a leader in power testing – bringing the most popular aspects of consumer tech into designs of solutions for the modern engineer.

"75 years is an outstanding accomplishment for any company,” Bohn says. “To have two companies, Tektronix and Keithley, come together linked through a common DNA of a focus on innovation, delivering outstanding value to our customers, strong well-respected brands, that come from decades of launching great products, that’s remarkable.”

The Model 2450 SourceMeter® SMU Instrument, the first Touch, Test, Invent® instrument, was introduced in 2013. This family, which now includes multiple SourceMeter instruments, DMMs and data acquisition instruments, uses a touchscreen with an intuitive graphical interface. All are designed to help users learn faster, work smarter and invent easier.

In 2020, Keithley teamed with Tektronix engineers in Nashville to take the test and measurement field into a whole new era with first of their kind data streaming and visualization solutions that allow engineers to interact with their captured waveforms remotely and simultaneously anywhere in the world through the cloud. The TekCloud has been a game changer for engineers who had been snapping and sharing photos of their data before this online development.

The Next 75 Years

So, when a Midwest company helps a shuttle go to the moon and now builds in collaboration across the cloud, what’s next?

To Brad Odhner, technical marketing manager and five-year Keithley employee, the future may be different, but it will still depend on power. “More and more industries see batteries as a necessity and a development opportunity. For Keithley, the test focus has shifted from simply precision to volume and speed,” he says. “This allows customers to make measurements across hundreds of test points very quickly and very accurately. We’re in a great position to help customers meet complex and evolving test needs with equipment they’re already familiar with and that doesn’t break the bank.”

For many of those customers, measuring their own success in the future is also quite different from the past. End users and investors are looking for solutions that don’t just deliver on usability and flexibility, they want solutions that use less energy and a minimal environmental impact – issues that all come back to where Keithley started: battery.

“If you can save even an hour on battery life, it has a huge ripple effect,” Bohn says, “and that will have an impact on our work on climate change.”