Temperature Calibration and Why It Matters: Accuracy, Safety, and Compliance

In virtually every industry, from pharmaceuticals to food processing and aerospace, temperature is a critical variable. The success of a process, the quality of a product, and even operational safety often depend on precise temperature control. But how do you ensure the thermometers, sensors, and controllers you rely on are telling the truth? The answer is temperature calibration.

This blog provides a clear and concise overview of temperature calibration. We’ll explore what it is, why it's essential, the key methods used, and the standards that guarantee reliability, empowering you to maintain control over your critical processes.

What is Temperature Calibration?

Temperature calibration is the process of comparing the temperature measurement from a device under test (DUT) against metrological standards typically traceable to the International System of Units (SI) through a national measurement institute (e.g., NIST). It's a precise comparison to verify that your instrument is measuring correctly. If deviations are found, adjustments can be made to bring the device back into its required performance specifications. The results are then formally documented in a calibration certificate.

Why Temperature Calibration is Essential for Your Operations

Neglecting temperature calibration introduces significant operational and financial risks. Regular calibration is an essential practice that safeguards your business by directly impacting product quality, preventing ruined batches in food, pharma, and manufacturing by ensuring processes like sterilization and curing occur at the correct temperature. This, in turn, enhances safety by protecting equipment and personnel from overheating or other temperature-related failures.

Furthermore, proper calibration drives efficiency, optimizing energy consumption in systems like HVAC and industrial furnaces so they are not working harder than needed due to faulty sensor readings. Finally, all these benefits are underpinned by the need for regulatory compliance. Documented, traceable calibration is a core requirement for standards like FDA, HACCP, and ISO 9001, providing the proof needed to pass critical audits.

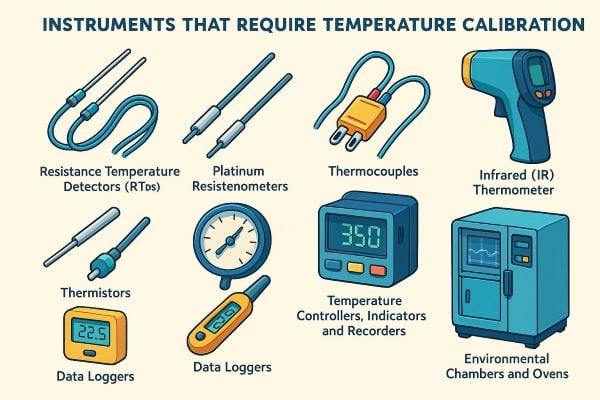

Common Instruments Requiring Temperature Calibration

A wide variety of temperature measurement instruments require periodic calibration to ensure they remain accurate. If a device's reading is used to make a critical decision, it needs to be calibrated. This includes:

- Resistance Temperature Detectors (RTDs) and Platinum Resistance Thermometers (PRTs)

- Thermocouples

- Thermistors

- Dial and Digital Thermometers

- Infrared (IR) Thermometers and Thermal Imagers

- Temperature Controllers, Indicators, and Recorders

- Data Loggers

- Environmental Chambers and Ovens

Tektronix supports Multi-Brand calibration across this entire range of instruments, including high-accuracy instruments used in aerospace, semiconductor, and pharmaceutical applications.

Key Temperature Calibration Methods Explained

There are several established methods for temperature calibration, chosen based on the required accuracy and the instrument being tested.

- Comparison Calibration is the most common approach. This involves placing the device under test (DUT) and a more accurate reference thermometer together in a stable temperature source, like a dry-block calibrator or a liquid bath. Their readings are then compared at various temperature points.

- Fixed-Point Calibration is used for the highest level of accuracy. This highly precise method utilizes the known, repeatable temperatures at which pure substances change their physical state (e.g., the triple point of water at 0.01 °C). It is typically employed in high-level laboratories to calibrate reference standards themselves.

- Simulator-Based Calibration is a third technique which tests only the electronics of a temperature measurement system, not the sensor. A simulator sends a precise electrical signal (voltage or resistance) to the display or controller to verify its accuracy. While fast, this method provides an incomplete picture of the overall system's performance.

At Tektronix, our accredited labs use both comparison and fixed-point calibration methods, ensuring traceability to ITS-90 and delivering industry-leading accuracy across a wide range of temperature instruments.

It’s also important to note that environmental conditions—such as ambient temperature stability, humidity, and air flow—can significantly influence calibration accuracy. Tektronix calibration labs maintain tightly controlled environments to ensure reliable results.

The Role of Standards: ITS-90 and Traceability

The reliability of temperature calibration is built upon globally recognized standards. The International Temperature Scale of 1990 (ITS-90) is the official framework that defines temperatures, providing the "recipe" for how temperature is measured consistently worldwide.

Traceability, often to the International System of Units (SI) through a national measurement institute - e.g., NIST in the US; is the documented, unbroken chain of comparisons that links your instrument's calibration back to these primary standards. This ensures your measurements are accurate and consistent with the global measurement system, which is a fundamental requirement for most quality systems

How Often Should You Calibrate Your Instruments?

The ideal calibration frequency is not a single, fixed rule but a calculated decision based on risk and need. While annual calibration is a common starting point, the optimal interval depends on several factors. Key considerations include the manufacturer’s recommendation, the criticality of the application—a sensor in a critical process needs more frequent calibration than a simple room thermostat, and the stability and history of the specific instrument. Advanced users may also employ control charts or drift analysis to monitor instrument stability over time and optimize calibration intervals based on actual performance trends. Additionally, the harshness of the operating environment and specific regulatory or quality system requirements must be taken into account. If an instrument is ever dropped or suspected of being inaccurate, it should be checked immediately, regardless of its schedule.

Understanding Your Calibration Certificate

A calibration certificate is more than just a pass/fail sticker; it's a detailed report of your instrument's performance. A comprehensive certificate provides crucial information, including the "As Found" data showing the instrument's condition before any adjustments, and the "As Left" data showing the final results. It must also identify the reference standards used, declare the calculated measurement of uncertainty for each point. For example, a high-accuracy RTD might have a measurement uncertainty of ±0.05 °C, while a thermocouple used in industrial settings may have an uncertainty of ±1.0 °C depending on the calibration method and range. Finally, the calibration certificate should include a formal statement of traceability to national standards. This document is your proof of due diligence and provides the data needed for quality audits.

How to Choose a Reliable Temperature Calibration Service

Choosing the right calibration partner is critical. Look for a provider with:

- ISO/IEC 17025 Accreditation: This is the key international standard for the technical competence of calibration labs.

- A Published Scope of Accreditation: Ensure their accredited capabilities cover your specific temperature ranges and instrument types.

- Low Measurement Uncertainties: A provider's stated uncertainty indicates their level of accuracy.

- Appropriate Capabilities: Do they offer the services you need, such as on-site calibration to minimize downtime?

- Efficient Turnaround Time (TAT) and clear communication.

As calibration becomes increasingly digital, Tektronix also offers online calibration management tools (CalWeb) that streamline scheduling, documentation, and compliance tracking for our customers.

Tektronix: Your Accredited Partner for Temperature Calibration

When process integrity and quality depend on precise temperature control, Tektronix provides the accredited calibration services you need. We offer Multi-Brand calibration for a vast range of temperature instruments, from RTDs and thermocouples to infrared thermometers and environmental chambers.

Our ISO/IEC 17025 accredited services traceable to the International System of Units (SI) through the National Institute of Standards and Technology (NIST) are designed to meet the most stringent regulatory requirements. With flexible options including on-site calibration to minimize your downtime and service at our high-precision labs, we tailor our solutions to your operational needs.

Our services support mission-critical applications where even a 0.1°C deviation can compromise safety or compliance. With decades of experience and a global footprint, Tektronix is your trusted partner for temperature calibration.

Tektronix is also actively involved in advancing calibration standards and methodologies through industry partnerships and technical leadership, ensuring our customers benefit from the latest innovations in metrology.

Ready to ensure your temperature measurements are accurate and reliable? Contact Tektronix today to discuss your specific requirements or to request a quote for our comprehensive temperature calibration services