Developing a new oscilloscope probe represents an interesting design challenge because it incorporates both mechanical and electrical elements along with a good dose of reality about what can and can’t be built. For the recently introduced P7700 Series TriMode probes, all those factors and more came into play.

The P7700 probes address the challenges faced by test engineers working with new semiconductor and hardware designs in the mobile and enterprise computing segments, which are notably different from the devices they’ve been developing for many years. For example, mobile devices that are battery powered are often running with lower voltage logic levels that make their acquisition and analysis more difficult. Also, semiconductor devices designed for low power consumption can operate with their I/O in a high impedance, unterminated state. These challenges require a low noise and high impedance acquisition system.

More on the mechanical side of things, the size of mobile and computing devices continues to shrink. With more power packed into a tighter space, there is a need for probing that can be used in tight spaces.

The Tektronix P7700 Series TriMode probes, for use with Tektronix performance oscilloscopes, deliver several innovations that improve the ability to probe and acquire signals in the face of these challenges along with upgradeable bandwidth support up to 20 GHz.

Industry First “Chip on the Tip”

The P7700 offers the industry’s first “Chip-on-the-Tip” design with the active input buffer on the solder tip. Built using IBM’s SiGe 8HP process, the probe tip amplifier is located less than 4 mm from the DUT connection which minimizes signal loss, capacitance and added noise. Not only is this innovation able to offer outstanding electrical performance, but it is also ESD tolerant and able to operate over an industrial temperature range of -40°C to +85°C.

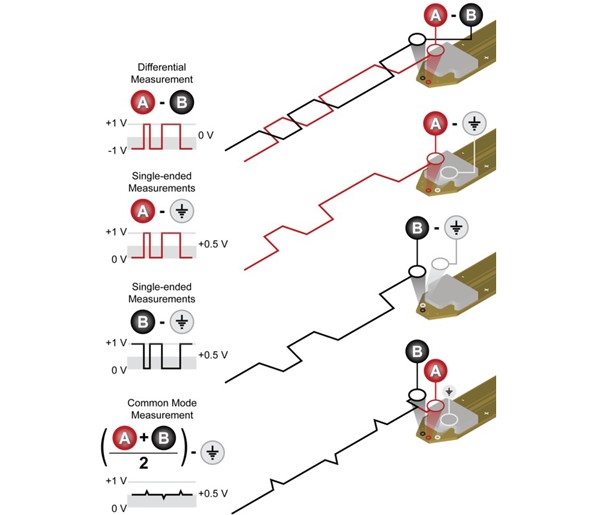

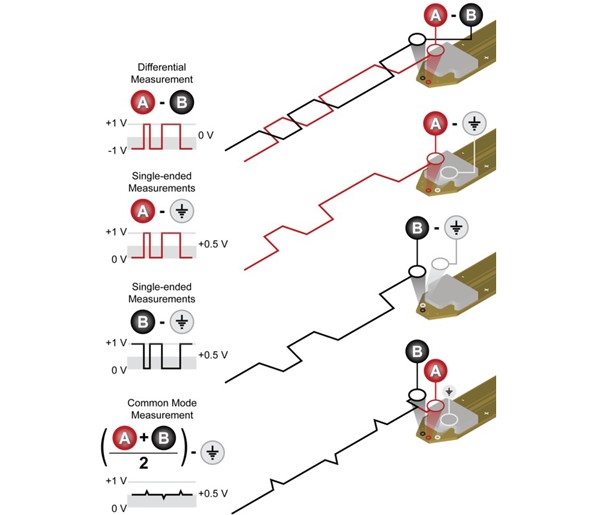

As shown in the image below, the probes support TriMode measurements: differential, single-ended and common mode. At the tip of the probe are plated through holes that allow small extension wires from the board test points to be threaded through and soldered onto the tip. Each of the inputs can be used to measure single-ended signals, with the ground pin as reference.

Connector Technology

Moving to the mechanical side, the P7700 probes introduce the new TekFlex™ connector technology for accessories as show below. The TekFlex connector combines high speed differential connections and low speed data and power connection all in one. With this connector design, the active chip-on-the-tip accessories receive power and control and connect via a high speed differential pair to the oscilloscope’s input.

This connector minimizes the hassle of attaching probe cables and limits potential damage to fragile wires and components on the device under test. With a simple pinching action, the TekFlex connector opens allowing the user to insert one of several probing accessories. Once closed the TekFlex connector securely holds the tip eliminating the worry of the probe connection coming off if the cable is accidentally pulled or bumped.

Connecting to a device with solder-in probe tips is a delicate operation that requires a lot of care in order to prevent breaking solder connections or fine features on the DUT. With an easy one handed, on and off mechanism, probes with TekFlex connectors are less likely to damage delicate connections on the device under test when the probe is connected or disconnected.

In addition to ease of use, engineers want probe connections that lower costs over years of use. If they damage the tip with use, they don’t want to worry about having to repair it. Rather they’d prefer to throw it away and use a new tip. In addition, when many probe points need to be checked, it is often easier to solder on a tip and leave it rather than removing it and risking damage to the tip or the DUT.

Both of these requirements present a need to reduce the cost per connection of the probe’s accessories. With the P7700 family of probes, Tektronix delivers the industry’s lowest cost per connection with a base price of $50 per solder-in tip. In addition, with the ability to reuse the tips many times, the cost per connection comes down to <$10. In tests, Tektronix technicians were able to reuse tips 10X, but of course your mileage may vary.

Easier Handheld Probing

The design of the pins for the P7700 browser accessory for handheld and fixtured probing incorporates several design innovations that have been protected by patent applications.

Using micro-fabrication techniques developed in close partnership with the manufacturing side, Tektronix designers have implemented a pogo pin like tip that is only .023” in diameter with a tip that is <10 mils. The narrow needle like tip is critical for probing today’s designs with very small pads and tightly spaced differential pairs.

The pin is a rod resistor design that works with the P7700’s chip-on-the-tip to provide a high impedance input that lowers loading on the DUT. This resistor is constructed of a super-ceramic material that is very resistant to breakage.

The browser tips are prominently placed on the front of the browser, so the user can see them from almost any probing angle. The new browser is shown in action below, showcasing its built-in LED light.

Low loading for LPDDR, MIPI

To save power, low power serial buses operate in different modes. During their low power state, these buses run in an unterminated, high-impedance state. Most probes have high impedance at DC, but as the signal under test’s frequency increases the input structure of the probe acts more capacitive, lowering its impedance. The P7700 series probes maintain a high impedance much higher in frequency than other 20 GHz capable probes. With higher input impedance, the P7700 series probes are less likely to load low power serial buses than other high bandwidth probes.

The probes also include S-parameter models stored in memory on the devices that are used for de-embedding of the probe’s impact on the circuit under test. This de-embedding operation occurs automatically, unlike other probes that require the user to connect their probe to a calibration fixture and run a complex process.

The P7700 probe address challenging problems engineers are facing day in and day out – namely the need for a low noise, high impedance signal acquisition system able to probe in tight spaces. Tektronix has delivered a complete solution involving both electrical and mechanical innovations and carefully considered designs.

To learn more about these new probes, download the P7700 Series datasheet. And be sure to watch this video to see these probes in action!