Contact us

Live Chat with Tek representatives. Available 6:00 AM - 4:30 PM

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

Kiểm tra năng lượng thông minh: Sạc, Xả, Tái tạo

Với nhu cầu di động ngày nay, pin cung cấp năng lượng cho mọi thứ từ hệ thống an ninh đến xe buýt—đòi hỏi phải kiểm tra nghiêm ngặt trong quá trình phát triển và sản xuất. Theo truyền thống, việc sạc sử dụng bộ cấp nguồn DC có thể lập trình, trong khi việc xả dựa vào tải điện tử hoặc tải điện trở. Hiện nay, các bộ cấp nguồn hai chiều và tái tạo như Elektro Automatik PSB Series kết hợp cả hai chức năng trong một thiết bị.

Dòng PSB hoạt động như cả nguồn DC và tải điện tử tái tạo năng lượng, chuyển đổi mượt mà giữa các chế độ. Hệ thống thu hồi năng lượng từ pin xả và đưa trở lại lưới điện địa phương, giúp giảm lãng phí năng lượng và chi phí sưởi ấm cho cơ sở. Các giải pháp của EA đi kèm tiêu chuẩn với phần mềm kiểm tra pin cho pin lithium-ion và chì-axit, giúp hợp lý hóa việc thử nghiệm đồng thời tiết kiệm không gian và vốn.

Tìm hiểu về:

Giải pháp ứng dụng

Kiểm tra pin

Sử dụng bộ cấp nguồn hai chiều EA PSB để kiểm tra pin hiệu quả

Nhờ đó, pin đã trở nên nhỏ hơn và ngày càng hiệu quả hơn. Để bắt kịp tốc độ phát triển của công nghệ, thiết bị dùng để kiểm tra công nghệ tiên tiến cũng cần phải hiện đại, linh hoạt và nhạy bén. Vì những lý do này, dòng sản phẩm bộ cấp nguồn DC có thể lập trình hai chiều PSB của EA Elektro-Automatik là sự lựa chọn hoàn hảo cho các thử nghiệm pin tiên tiến.

Nguồn cung cấp hai chiều PSB có thể chuyển đổi liền mạch giữa việc cung cấp điện để sạc pin và điều khiển quá trình xả pin. Các chức năng kiểm tra sạc pin tích hợp, xả tĩnh điện và kiểm tra động được bao gồm trong các dòng sản phẩm PSB, PSI, EL và ELR. EA có thể hỗ trợ trong việc xác định thiết bị phù hợp nhất và cung cấp một số hướng dẫn cơ bản cùng các yếu tố cần xem xét để xây dựng một hệ thống kiểm tra pin mạnh mẽ, nhằm đảm bảo an toàn và hoạt động đúng cách của tất cả thiết bị kiểm tra và pin đang được kiểm tra.

Lợi thế:

- Chức năng kiểm tra tĩnh điện, phóng tĩnh điện và kiểm tra động được tích hợp trong chức năng tự động điều chỉnh phạm vi

- Mật độ công suất

- Hai chiều và tái tạo năng lượng

- Máy tạo dạng sóng và chức năng tùy ý

- EMC thấp

- Điện áp đầu ra lên đến 2000V

- Kết nối và sử dụng ngay (Plug and play)

Sạc pin

Sử dụng bộ cấp nguồn DC có thể lập trình để sạc pin, chẳng hạn như pin lithium-ion.

Khách hàng thường gửi yêu cầu cho các bộ sạc pin công suất trung bình hoặc cao để phục vụ các dự án khác nhau liên quan đến điện khí hóa phương tiện (EV), chẳng hạn như xe đạp điện, xe hơi hybrid hoặc xe tải điện hoàn toàn. Những bộ sạc pin này thường được sử dụng như một phần của giàn kiểm tra pin trong môi trường xe điện (EV) để thực hiện các bài kiểm tra chu kỳ, hiệu suất và tuổi thọ. Ngoài ra, các giàn kiểm tra thường sẽ được trang bị các cơ chế điều khiển, giám sát và an toàn phù hợp với loại pin mà chúng sẽ kiểm tra.

Các giàn kiểm tra nhằm vào việc kiểm tra pin sẽ đòi hỏi bộ cấp nguồn DC có thể lập trình với giao diện phù hợp (tương tự hoặc kỹ thuật số, ví dụ: CAN) có độ chính xác cao, độ phân giải tốt và độ gợn sóng thấp. Nó có thể đóng vai trò như một xương sống nguồn DC có thể điều chỉnh và rất linh hoạt, cho phép giàn kiểm tra kết nối với nhiều loại pin hoặc bộ pin khác nhau với điện áp và dung lượng danh định khác nhau. Bộ cấp nguồn EA có tính năng sạc pin tích hợp, sẽ tự động dừng khi đạt đến điện áp sạc hoặc khi dung lượng pin đạt mức quy định.

Lợi thế:

- Chức năng kiểm tra tĩnh điện, phóng tĩnh điện và kiểm tra động được tích hợp trong tự động điều chỉnh phạm vi

- Mật độ công suất

- Hai chiều và tái tạo năng lượng

- Máy tạo dạng sóng tùy ý và chức năng

- EMC thấp

- Điện áp đầu ra lên tới 2000V

- Kết nối và sử dụng ngay (Plug and play)

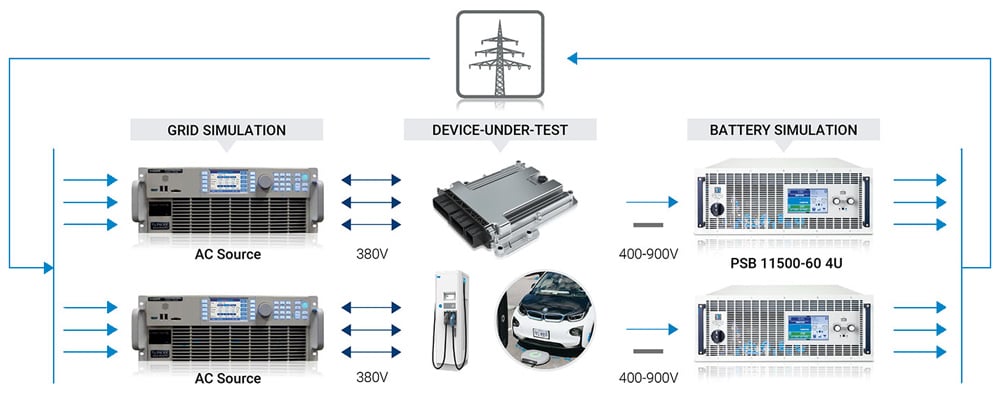

Mô phỏng pin

Sử dụng bộ cấp nguồn DC hai chiều có thể lập trình để mô phỏng pin chì-axit và pin lithium ion.

Bộ cấp nguồn DC hai chiều, về bản chất, là hoàn hảo để mô phỏng pin nhờ khả năng vừa cung cấp vừa tiêu thụ điện năng. Bằng cách thực hiện một đường cong hoạt động mô phỏng một loại pin cụ thể, kỹ sư kiểm tra có thể tái tạo chính xác công suất pin để kiểm tra các thiết bị cung cấp sạc hoặc nhận năng lượng từ pin. Phần mềm mô phỏng pin của Elektro-Automatik cho phép mô phỏng cả pin chì-axit và pin lithium-ion, bao gồm các đặc tính điện và hóa học của chúng trong quá trình sạc hoặc xả.

Hợp tác với Viện Fraunhofer danh tiếng tại Đức, EA đã phát triển các thuật toán để mô phỏng pin, được hỗ trợ bởi nhiều năm nghiên cứu. Giờ đây, có thể mô phỏng một bộ pin ở trạng thái sạc cụ thể (SOC) chỉ trong vài phút, thay vì phải chờ pin sạc hoặc xả đến cùng trạng thái SOC. Phần mềm cũng xem xét dung lượng pin, điện trở bên trong, nhiệt độ môi trường và thậm chí cả trạng thái sức khỏe (SOH).

Lợi thế:

- Thuật toán được phát triển với sự hợp tác cùng Viện Fraunhofer

- Tự động điều chỉnh

- Mật độ công suất

- Mô phỏng pin

- Hai chiều và tái tạo năng lượng

- Máy tạo dạng sóng và chức năng tùy ý

- EMC thấp

- Điện áp đầu ra lên tới 2000V

- Đấu song song cắm và chạy