Contact us

Live Chat with Tek representatives. Available 6:00 AM - 4:30 PM

Call us at

Available 6:00 AM – 5:00 PM (PST) Business Days

Download

Download Manuals, Datasheets, Software and more:

Feedback

2 Series MSO Quick Start

Install and set up your 2 Series MSO. This manual introduces the user interface and basic oscilloscope operations.

This manual applies to:

MSO22, MSO24, MSO22-EDU, MSO24-EDU

By downloading, you agree to the terms and conditions of the Manuals Download Agreement.

Manuals Download Agreement

ATTENTION: please read the following terms and conditions carefully before downloading any documents from this website. By downloading manuals from Tektronix' website, you agree to the following terms and conditions:

Manuals for Products That Are Currently Supported:

Tektronix hereby grants permission and license to owners of Tektronix instruments to download and reproduce the manuals on this website for their own internal or personal use. Manuals for currently supported products may not be reproduced for distribution to others unless specifically authorized in writing by Tektronix, Inc.

A Tektronix manual may have been revised to reflect changes made to the product during its manufacturing life. Thus, different versions of a manual may exist for any given product. Care should be taken to ensure that one obtains the proper manual version for a specific product serial number.

Manuals for Products That Are No Longer Supported:

Tektronix cannot provide manuals for measurement products that are no longer eligible for long term support. Tektronix hereby grants permission and license for others to reproduce and distribute copies of any Tektronix measurement product manual, including user manuals, operator's manuals, service manuals, and the like, that (a) have a Tektronix Part Number and (b) are for a measurement product that is no longer supported by Tektronix.

A Tektronix manual may be revised to reflect changes made to the product during its manufacturing life. Thus, different versions of a manual may exist for any given product. Care should be taken to ensure that one obtains the proper manual version for a specific product serial number.

This permission and license does not apply to any manual or other publication that is still available from Tektronix, or to any manual or other publication for a video production product or a color printer product.

Disclaimer:

Tektronix does not warrant the accuracy or completeness of the information, text, graphics, schematics, parts lists, or other material contained within any measurement product manual or other publication that is not supplied by Tektronix or that is produced or distributed in accordance with the permission and license set forth above.

Tektronix may make changes to the content of this website or to its products at any time without notice.

Limitation of Liability:

TEKTRONIX SHALL NOT BE LIABLE FOR ANY DAMAGES WHATSOEVER (INCLUDING, WITHOUT LIMITATION, ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES, DAMAGES FOR LOSS OF PROFITS, BUSINESS INTERRUPTION, OR FOR INFRINGEMENT OF INTELLECTUAL PROPERTY) ARISING OUT OF THE USE OF ANY MEASUREMENT PRODUCT MANUAL OR OTHER PUBLICATION PRODUCED OR DISTRIBUTED IN ACCORDANCE WITH THE PERMISSION AND LICENSE SET FORTH ABOVE.

Read Online

OPERATING BASICS

- Add a channel waveform to the display

- Configure channel or waveform settings

- Autoset to quickly display a waveform

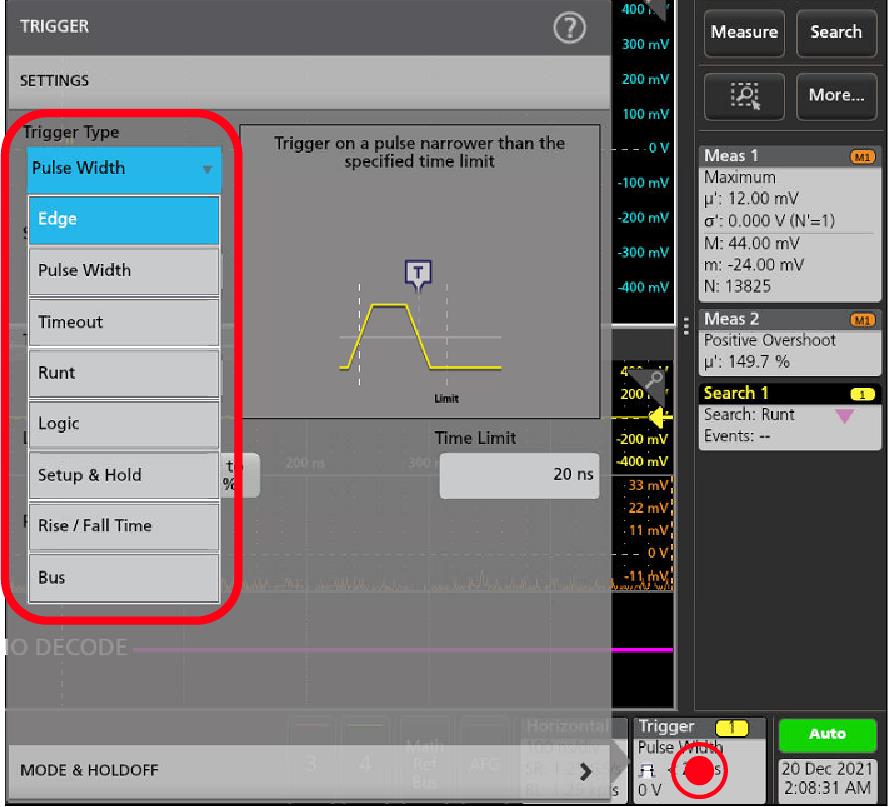

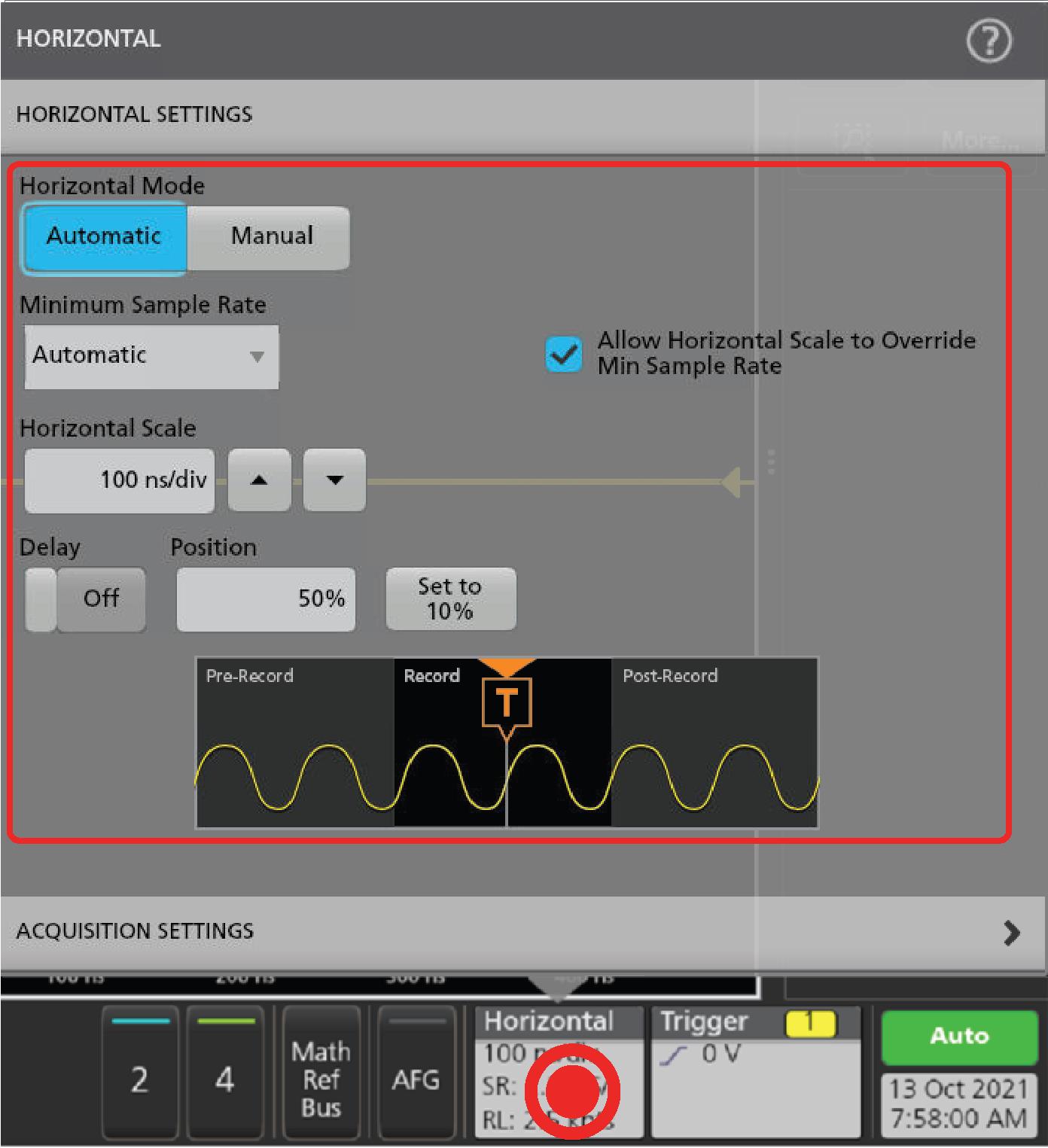

- How to trigger on a signal

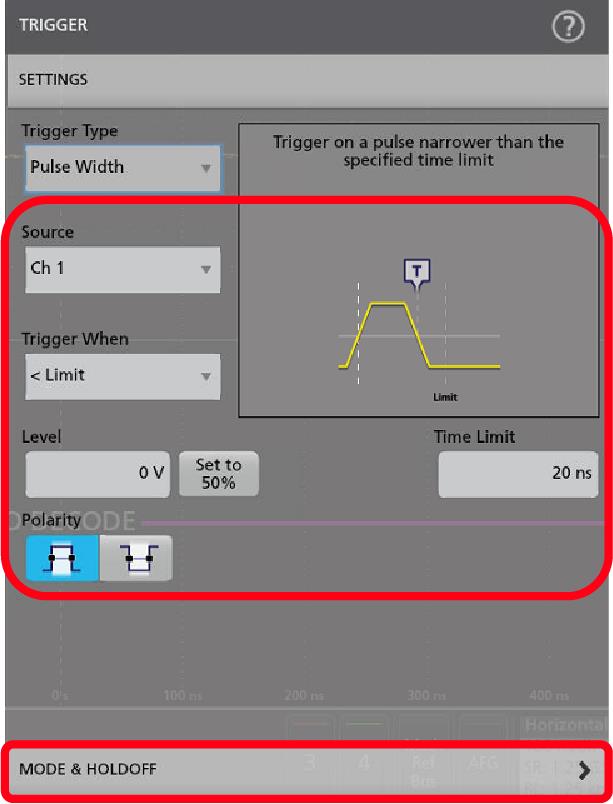

- Set the acquisition mode

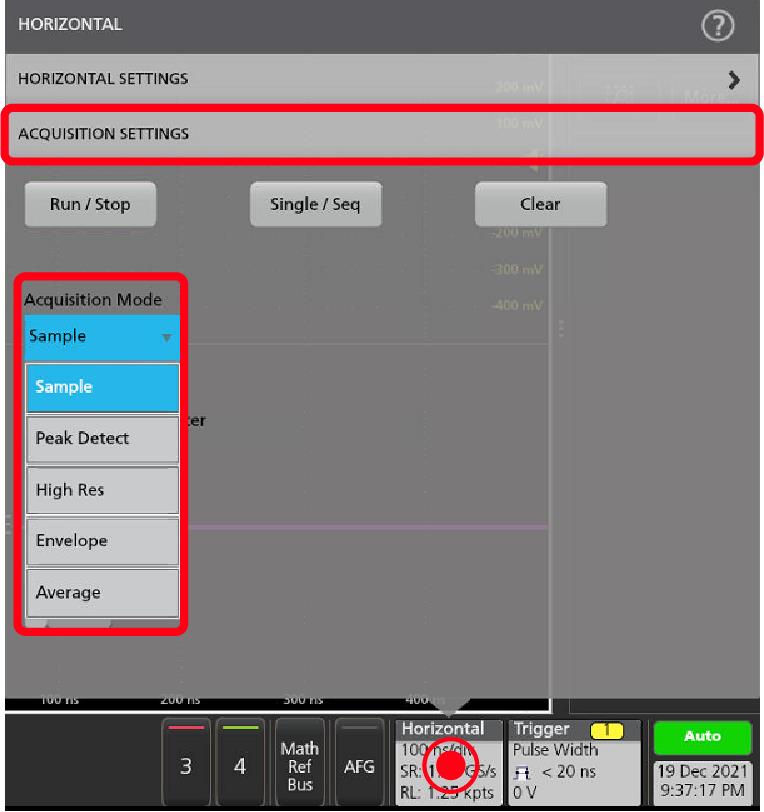

- Set Horizontal parameters

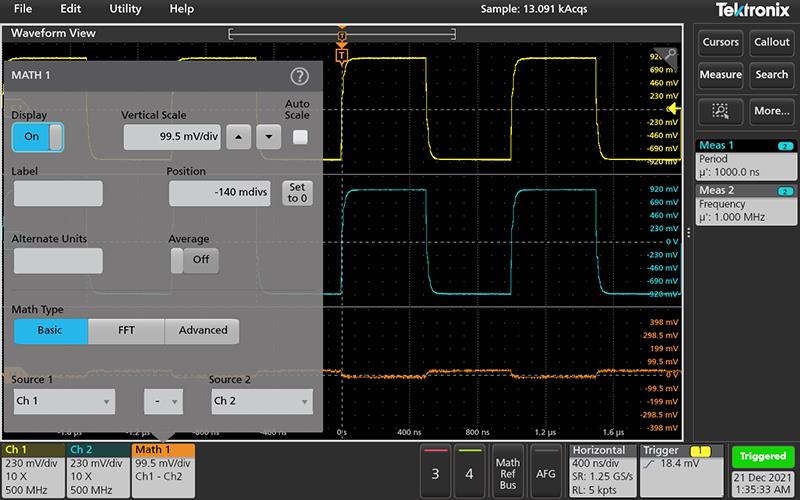

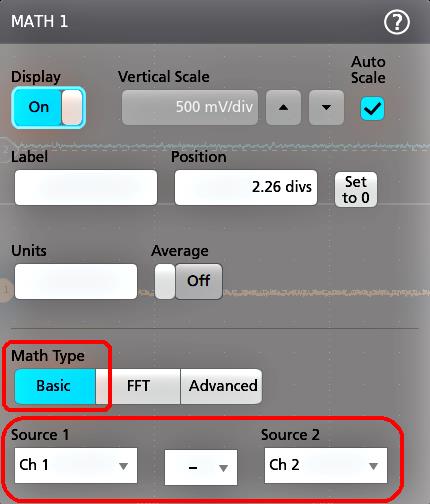

- Add a math, reference, or bus waveform

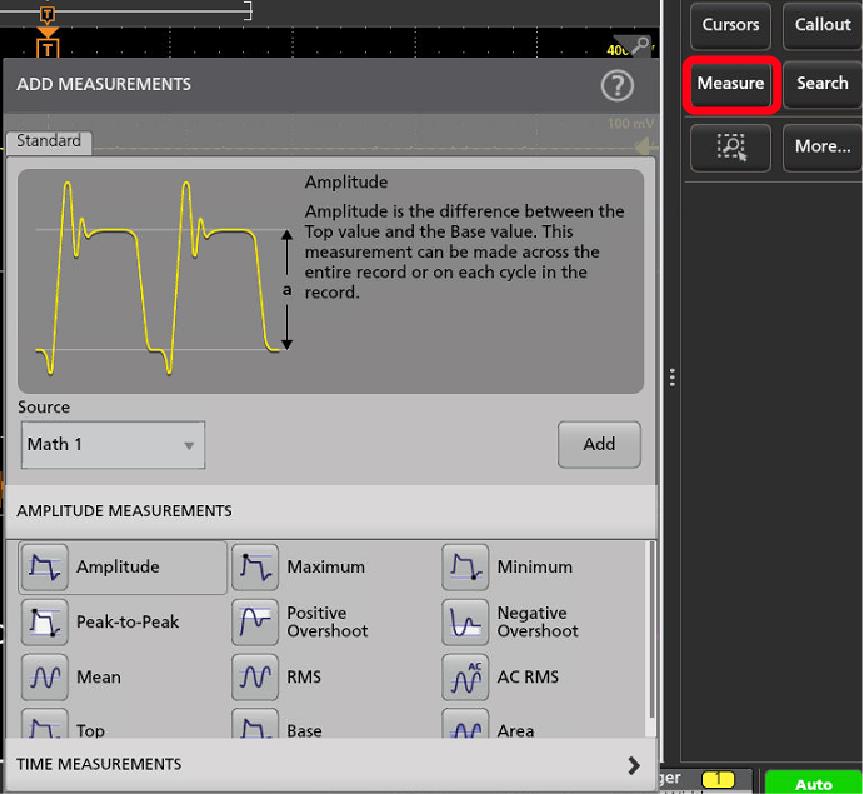

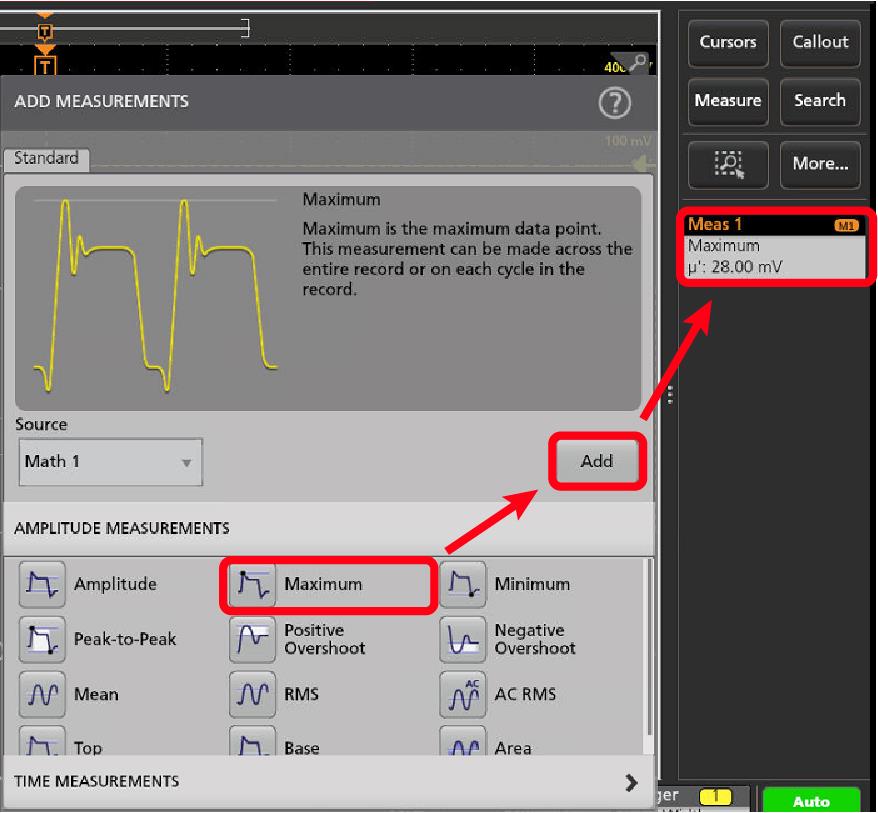

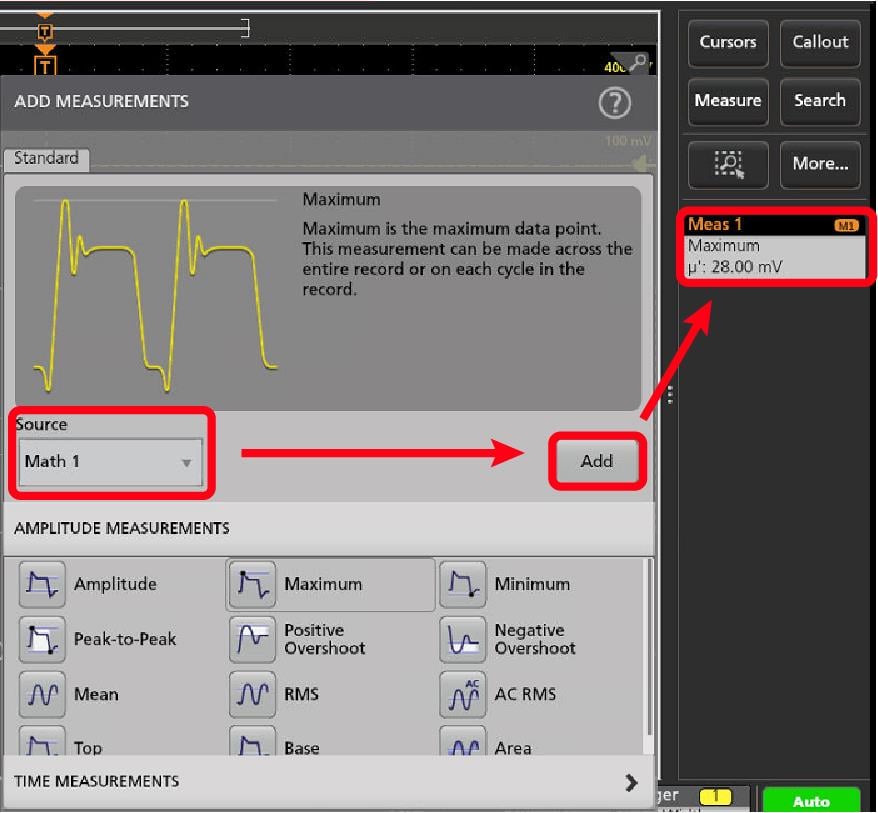

- Add a measurement

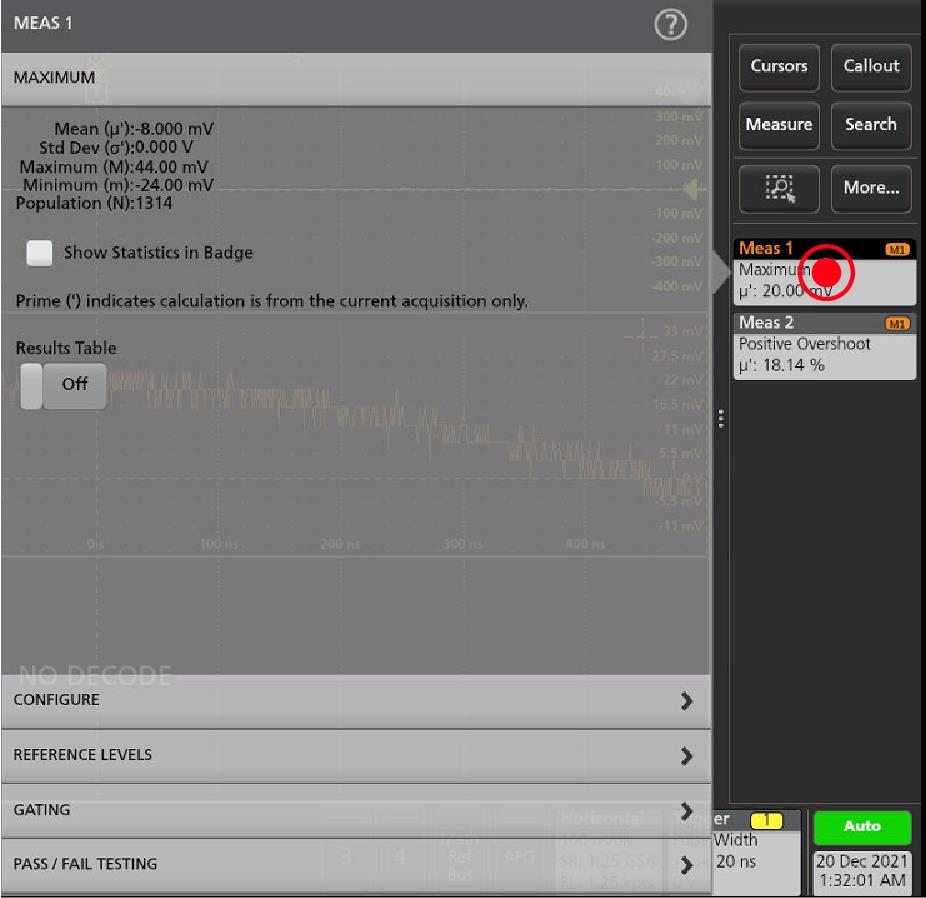

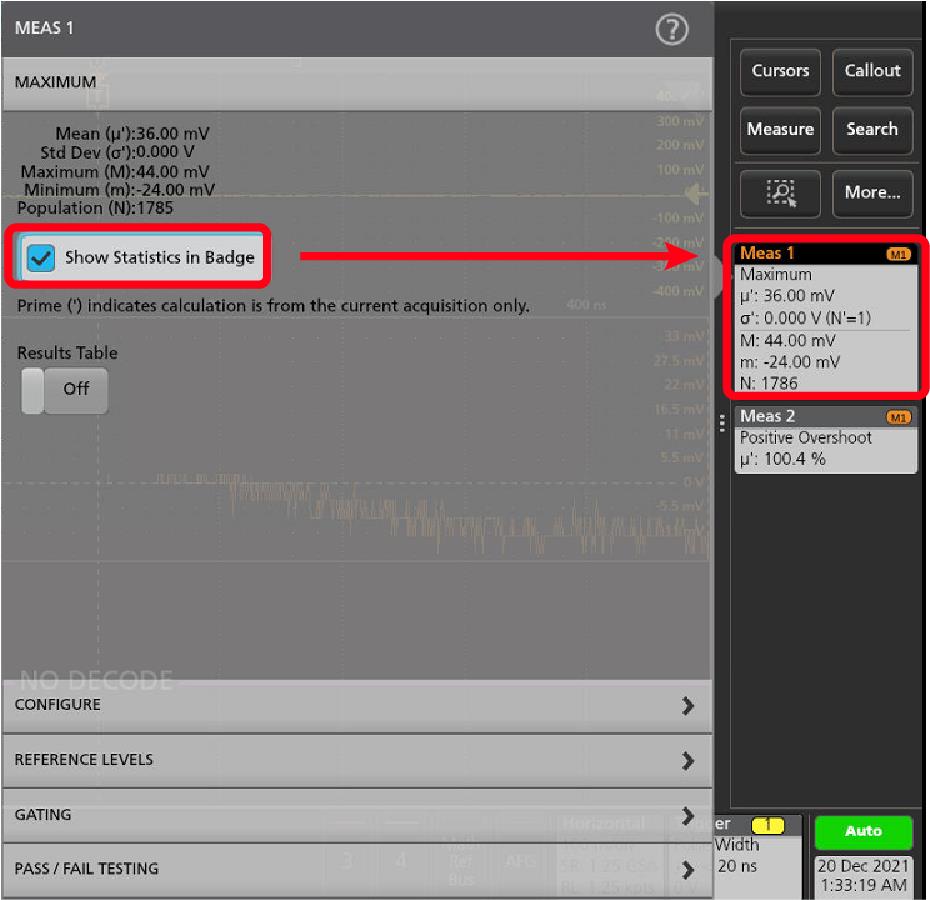

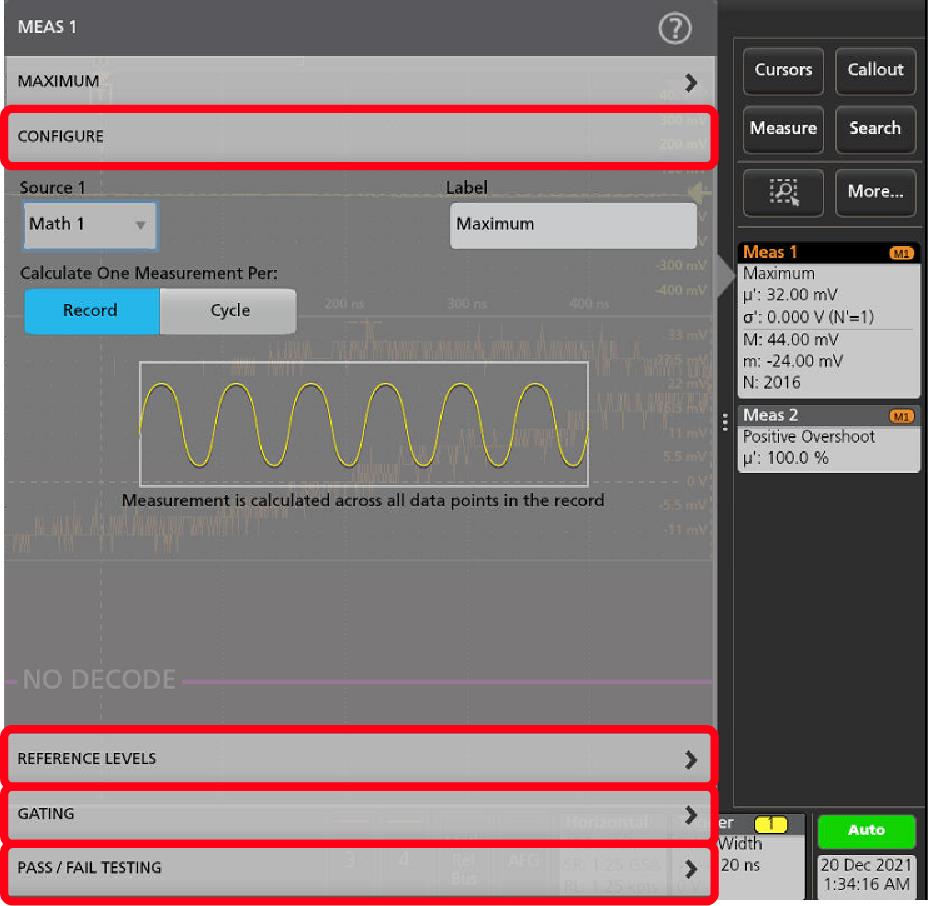

- Configure a measurement

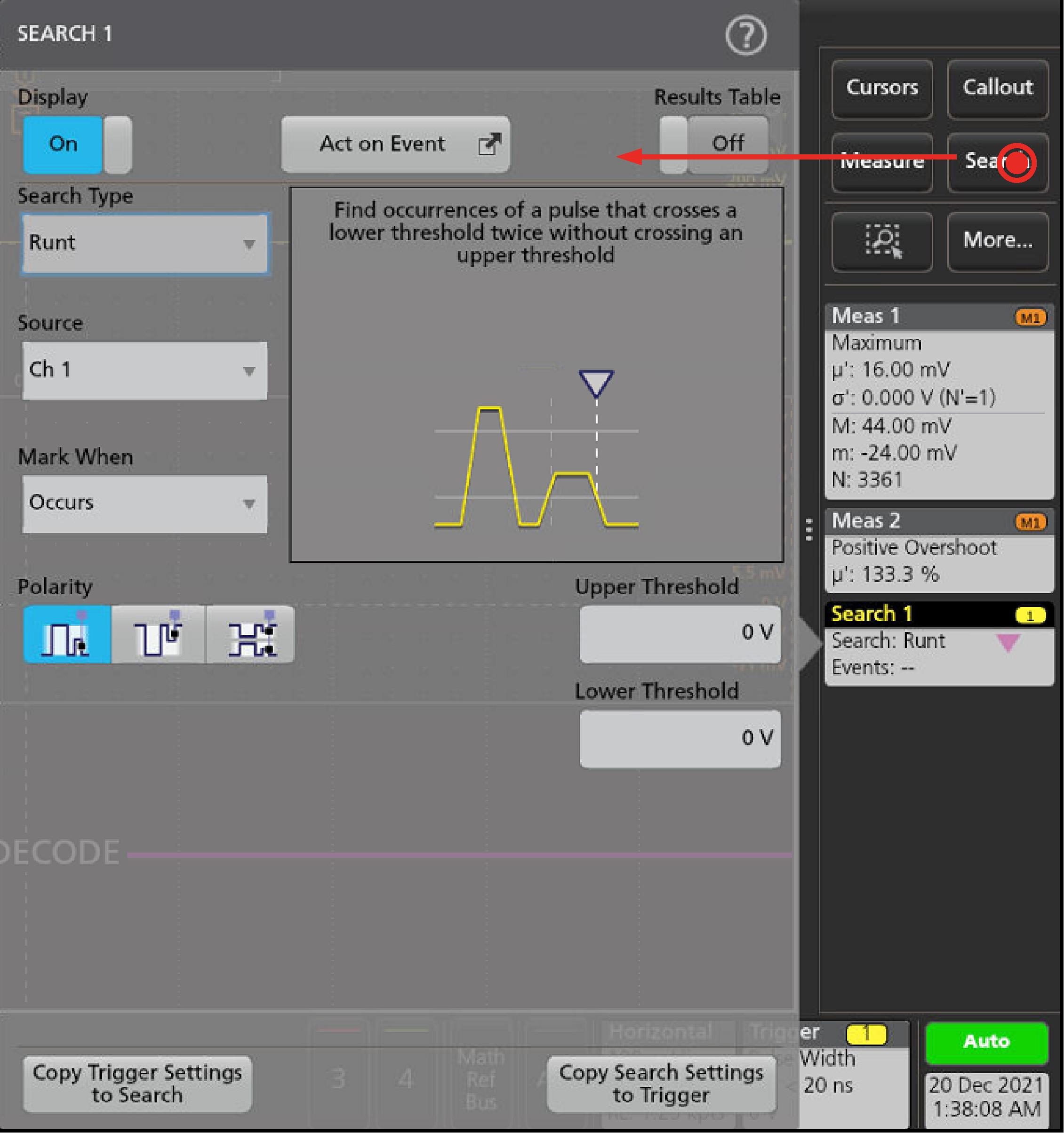

- Add a Search

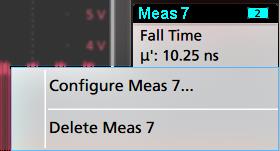

- Delete a Measurement or Search badge

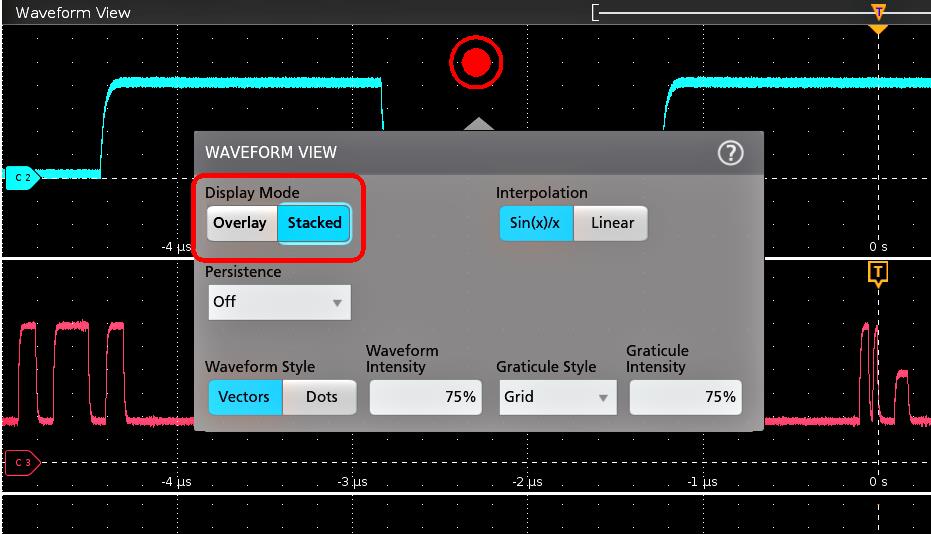

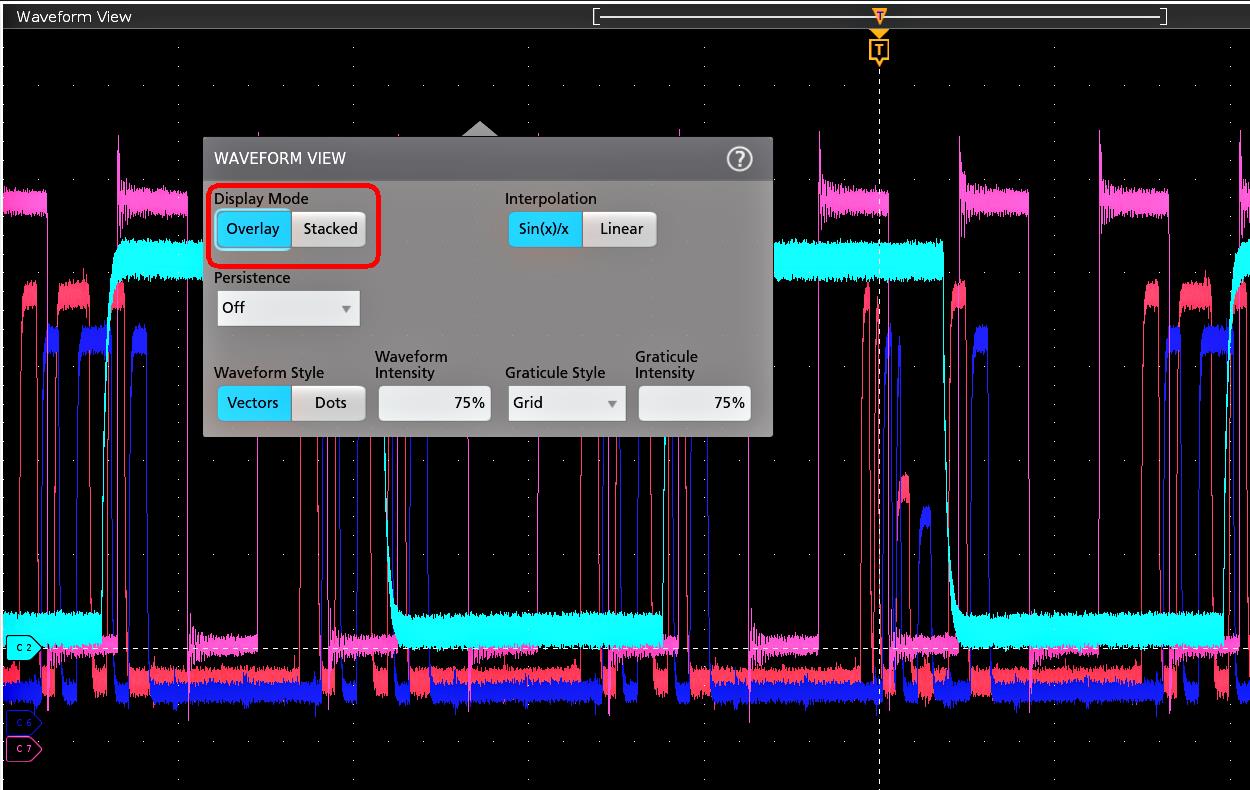

- Change waveform view settings

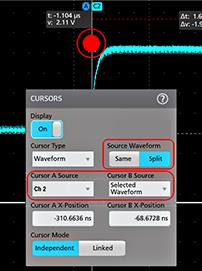

- Display and configure cursors

- Connect the oscilloscope to a PC using a USB cable

- ESD Prevention Guidelines

Important safety information

This manual contains information and warnings that must be followed by the user for safe operation and to keep the product in a safe condition.

To safely perform service on this product, see the Service safety summary that follows the General safety summary.

General safety summary

Use the product only as specified. Review the following safety precautions to avoid injury and prevent damage to this product or any products connected to it. Carefully read all instructions. Retain these instructions for future reference.

This product shall be used in accordance with local and national codes.

For correct and safe operation of the product, it is essential that you follow generally accepted safety procedures in addition to the safety precautions specified in this manual.

The product is designed to be used by trained personnel only.

Only qualified personnel who are aware of the hazards involved should remove the cover for repair, maintenance, or adjustment.

Before use, always check the product with a known source to be sure it is operating correctly.

This product is not intended for detection of hazardous voltages.

Use personal protective equipment to prevent shock and arc blast injury where hazardous live conductors are exposed.

While using this product, you may need to access other parts of a larger system. Read the safety sections of the other component manuals for warnings and cautions related to operating the system.

When incorporating this equipment into a system, the safety of that system is the responsibility of the assembler of the system.

To avoid fire or personal injury

Use proper power cord

Use only the power cord specified for this product and certified for the country of use. Do not use the provided power cord for other products.

Ground the product

This product is grounded through the grounding conductor of the power cord. To avoid electric shock, the grounding conductor must be connected to earth ground. Before making connections to the input or output terminals of the product, ensure that the product is properly grounded. Do not disable the power cord grounding connection.

Power disconnect

The power cord disconnects the product from the power source. See instructions for the location. Do not position the equipment so that it is difficult to operate the power cord; it must remain accessible to the user at all times to allow for quick disconnection if needed.

Use proper AC adapter

Use only the AC adapter specified for this product.

Connect and disconnect properly

Do not connect or disconnect probes or test leads while they are connected to a voltage source.

Use only insulated voltage probes, test leads, and adapters supplied with the product, or indicated by Tektronix to be suitable for the product.

Connect the probe output to the measurement instrument before connecting the probe to the circuit under test. Connect the probe reference lead to the circuit under test before connecting the probe input. Disconnect the probe input and the probe reference lead from the circuit under test before disconnecting the probe from the measurement instrument.

De-energize the circuit under test before connecting or disconnecting the current probe.

Observe all terminal ratings

To avoid fire or shock hazard, observe all rating and markings on the product. Consult the product manual for further ratings information before making connections to the product.

Do not exceed the Measurement Category (CAT) rating and voltage or current rating of the lowest rated individual component of a product, probe, or accessory. Use caution when using 1:1 test leads because the probe tip voltage is directly transmitted to the product.

Do not apply a potential to any terminal, including the common terminal, that exceeds the maximum rating of that terminal.

Do not float the common terminal above the rated voltage for that terminal.

The measurement terminals on this product are not rated for connection to Category III or IV circuits.

Do not connect a current probe to any wire that carries voltages above the current probe voltage rating.

Do not operate without covers

Do not operate this product with covers or panels removed, or with the case open. Hazardous voltage exposure is possible.

Avoid exposed circuitry

Do not touch exposed connections and components when power is present.

Do not operate with suspected failures

If you suspect that there is damage to this product, have it inspected by qualified service personnel.

Disable the product if it is damaged. Do not use the product if it is damaged or operates incorrectly. If in doubt about safety of the product, turn it off and disconnect the power cord. Clearly mark the product to prevent its further operation.

Before use, inspect voltage probes, test leads, and accessories for mechanical damage and replace when damaged. Do not use probes or test leads if they are damaged, if there is exposed metal, or if a wear indicator shows.

Examine the exterior of the product before you use it. Look for cracks or missing pieces.

Use only specified replacement parts.

Replace batteries properly

Replace batteries only with the specified type and rating.

Recharge batteries for the recommended charge cycle only.

Wear eye protection

Wear eye protection if exposure to high-intensity rays or laser radiation exists.

Do not operate in wet/damp conditions

Be aware that condensation may occur if a unit is moved from a cold to a warm environment.

Do not operate in an explosive atmosphere

Keep product surfaces clean and dry

Remove the input signals before you clean the product.

Provide proper ventilation

Refer to the installation instructions in the manual for details on installing the product so it has proper ventilation.

Slots and openings are provided for ventilation and should never be covered or otherwise obstructed. Do not push objects into any of the openings.

Provide a safe working environment

Always place the product in a location convenient for viewing the display and indicators.

Avoid improper or prolonged use of keyboards, pointers, and button pads. Improper or prolonged keyboard or pointer use may result in serious injury.

Be sure your work area meets applicable ergonomic standards. Consult with an ergonomics professional to avoid stress injuries.

Use only the Tektronix rackmount hardware specified for this product.

Probes and test leads

Before connecting probes or test leads, connect the power cord from the power connector to a properly grounded power outlet.

Keep fingers behind the protective barrier, protective finger guard, or tactile indicator on the probes. Remove all probes, test leads and accessories that are not in use.

Use only correct Measurement Category (CAT), voltage, temperature, altitude, and amperage rated probes, test leads, and adapters for any measurement.

Beware of high voltages

Understand the voltage ratings for the probe you are using and do not exceed those ratings. Two ratings are important to know and understand:

- The maximum measurement voltage from the probe tip to the probe reference lead.

- The maximum floating voltage from the probe reference lead to earth ground.

These two voltage ratings depend on the probe and your application. Refer to the Specifications section of the manual for more information.

| WARNING:To prevent electrical shock, do not exceed the maximum measurement or maximum floating voltage for the oscilloscope input BNC connector, probe tip, or probe reference lead. |

Connect and disconnect properly.

Connect the probe output to the measurement product before connecting the probe to the circuit under test. Connect the probe reference lead to the circuit under test before connecting the probe input. Disconnect the probe input and the probe reference lead from the circuit under test before disconnecting the probe from the measurement product.

De-energize the circuit under test before connecting or disconnecting the current probe.

Connect the probe reference lead to earth ground only.

Do not connect a current probe to any wire that carries voltages or frequencies above the current probe voltage rating.

Inspect the probe and accessories

Before each use, inspect probe and accessories for damage (cuts, tears, or defects in the probe body, accessories, or cable jacket). Do not use if damaged.

Ground-referenced oscilloscope use

Do not float the reference lead of this probe when using with ground-referenced oscilloscopes. The reference lead must be connected to earth potential (0 V).

Floating measurement use

Do not float the reference lead of this probe above the rated float voltage.

Service safety summary

The Service safety summary section contains additional information required to safely perform service on the product. Only qualified personnel should perform service procedures. Read this Service safety summary and the General safety summary before performing any service procedures.

To avoid electric shock

Do not touch exposed connections.

Do not service alone

Do not perform internal service or adjustments of this product unless another person capable of rendering first aid and resuscitation is present.

Disconnect power

To avoid electric shock, switch off the product power and disconnect the power cord from the mains power before removing any covers or panels, or opening the case for servicing.

Use care when servicing with power on

Dangerous voltages or currents may exist in this product. Disconnect power, remove battery (if applicable), and disconnect test leads before removing protective panels, soldering, or replacing components.

Verify safety after repair

Always recheck ground continuity and mains dielectric strength after performing a repair.

Terms in this manual

These terms may appear in this manual:

| WARNING:Warning statements identify conditions or practices that could result in injury or loss of life. |

| CAUTION:Caution statements identify conditions or practices that could result in damage to this product or other property. |

Terms on the product

These terms may appear on the product:

- DANGER indicates an injury hazard immediately accessible as you read the marking.

- WARNING indicates an injury hazard not immediately accessible as you read the marking.

- CAUTION indicates a hazard to property including the product.

Symbols on the product

|

| When this symbol is marked on the product, be sure to consult the manual to find out the nature of the potential hazards and any actions which have to be taken to avoid them. (This symbol may also be used to refer the user to ratings in the manual.) |

The following symbols(s) may appear on the product.

CAUTION: Refer to Manual |  Protective Ground (Earth) Terminal |  Earth Terminal |  Chassis Ground |  WARNING: High Voltage |  Breakable. Do not drop. |

Standby |  Functional Earth Terminal |  Use only on an insulated wire. |  Connection and disconnection to hazardous bare wire permitted. |  Do not connect to or remove from an uninsulated conductor that is HAZARDOUS LIVE. |

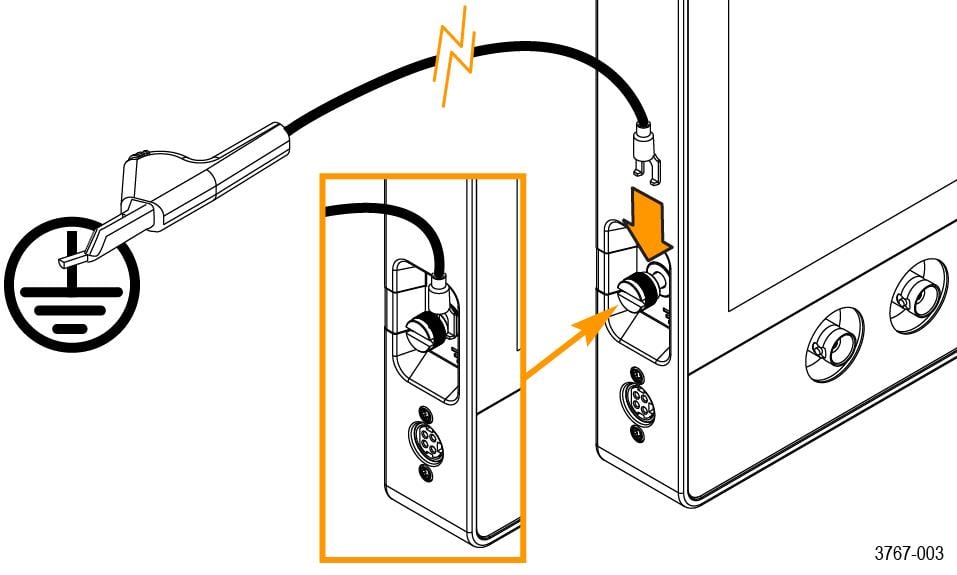

Operating safely with battery power

For safe operation, the instrument chassis should always remain at earth ground potential.

| WARNING:To avoid electric shock, always use the Tektronix-provided grounding cable when the oscilloscope is operating on battery power and not connected to the external power supply. The Tektronix-provided grounding cable is not for permanent usage. |

Without a connection between the chassis and earth ground, you may receive a shock from exposed metal on the chassis if you connect an input to a hazardous voltage (>30 VRMS, >42 Vpk). To protect yourself against possible shock, attach the Tektronix-provided grounding cable.

The grounding cable is necessary to provide protective bonding between the oscilloscope and a dedicated earthing terminal, in accordance with the NEC, CEC, and local codes. Consider having a qualified electrician to approve the installation.

The grounding cable shall be connected before powering on the oscilloscope and before attaching the probes to any circuit. Connect the grounding cable from the ground lug terminal on the side panel of the instrument to a dedicated earthing terminal. Make sure the teeth of the alligator clip makes good electrical contact and is secured against slipping.

The alligator clip on the grounding cable must be connected to a dedicated earthing terminal, an earthing terminal bar, or identified equipment grounding points (a rack cabinet for example). Make sure you have a good electrical connection to an appropriate grounding device that is identified with a Protective Earth symbol, or the word GROUND/GND, or the color green (green ground screw/conductor). If none of these are present, assume the connection is not earthed.

Always verify that the grounding cable is making good electrical contact by using an ohmmeter or continuity meter between the dedicated earthing terminal and the ground lug terminal on the side panel of the oscilloscope. Verify again anytime the oscilloscope has been left unattended.

Make sure the dedicated earthing terminal is located in close proximity to the circuit under test. Keep the grounding cable clear of heat sources and mechanical hazards such as; sharp edges, screw threads, moving parts, and closing doors/covers. Inspect the cable, insulation, and terminal ends for damage before use. Do not use a damaged grounding cable. Contact Tektronix for a replacement.

If you choose not to attach the grounding cable, you are not protected against electric shock if you connect the oscilloscope to a hazardous voltage. You can still use the oscilloscope if you do not connect a signal greater than 30 VRMS (42 Vpk) to the probe tip, the BNC connector center, or the common lead. Make sure all probe common leads are connected to the same voltage.

| WARNING:Hazardous voltages may exist in unexpected places due to faulty circuitry in the device under test. |

| CAUTION:When operating the instrument on battery power do not connect a grounded device, such as a printer or computer, to the oscilloscope unless the instrument grounding cable is connected to the earth ground. |

Compliance information

This section lists the safety and environmental standards with which the instrument complies. This product is intended for use by professionals and trained personnel only; it is not designed for use in households or by children.

Compliance questions may be directed to the following address:

Tektronix, Inc.

PO Box 500, MS 19-045

Beaverton, OR 97077, US

tek.com

Safety compliance

This section lists other safety compliance information.

Equipment type

Test and measuring equipment.

Safety class

Class 1 – grounded product.

Pollution degree description

A measure of the contaminants that could occur in the environment around and within a product. Typically the internal environment inside a product is considered to be the same as the external. Products should be used only in the environment for which they are rated.

- Pollution Degree 1. No pollution or only dry, nonconductive pollution occurs. Products in this category are generally encapsulated, hermetically sealed, or located in clean rooms.

- Pollution Degree 2. Normally only dry, nonconductive pollution occurs. Occasionally a temporary conductivity that is caused by condensation must be expected. This location is a typical office/home environment. Temporary condensation occurs only when the product is out of service.

- Pollution Degree 3. Conductive pollution, or dry, nonconductive pollution that becomes conductive due to condensation. These are sheltered locations where neither temperature nor humidity is controlled. The area is protected from direct sunshine, rain, or direct wind.

- Pollution Degree 4. Pollution that generates persistent conductivity through conductive dust, rain, or snow. Typical outdoor locations.

Pollution degree rating

Pollution Degree 2 (as defined in IEC 61010-1)

Measurement and overvoltage category descriptions

Measurement terminals on this product may be rated for measuring mains voltages from one or more of the following categories (see specific ratings marked on the product and in the manual).

- Overvoltage Category I. For equipment intended to be connected to a mains supply in which means have been taken to substantially and reliably reduce transient overvoltages to a level where they cannot cause a hazard.

- Measurement Category II. For measurements performed on circuits directly connected to the low-voltage installation.

- Measurement Category III. For measurements performed in the building installation.

- Measurement Category IV. For measurements performed at the source of low-voltage installation.

| Note:Only mains power supply circuits have an overvoltage category rating. Only

measurement circuits have a measurement category rating. Other circuits within the

product do not have either rating. |

Mains overvoltage category rating

Overvoltage Category I (as defined in IEC 60364)

Environmental compliance

This section provides information about the environmental impact of the product.

Product end-of-life handling

Observe the following guidelines when recycling an instrument or component:

- Equipment recycling

- Production of this equipment required the extraction and use of natural resources. The equipment may contain substances that could be harmful to the environment or human health if improperly handled at the product’s end of life. To avoid release of such substances into the environment and to reduce the use of natural resources, we encourage you to recycle this product in an appropriate system that will ensure that most of the materials are reused or recycled appropriately.

|

This symbol indicates that this product complies with the applicable European Union requirements according to Directives 2012/19/EU and 2006/66/EC on waste electrical and electronic equipment (WEEE) and batteries. For information about recycling options, check the Tektronix Web site (http://www.tek.com/productrecycling). |

- Battery recycling

- This product contains a small installed lithium metal button cell. Please properly dispose of or recycle the cell at its end of life according to local government regulations.

- Rechargeable batteries are subject to disposal and recycling regulations that vary by country and region. Always check and follow your applicable regulations before disposing of any battery. Contact Rechargeable Battery Recycling Corporation (www.rbrc.org) for U.S.A. and Canada, or your local battery recycling organization.

- Many countries prohibit the disposal of waste batteries in standard waste receptacles.

- Place only discharged batteries in a battery collection container. Use electrical tape or other approved covering over the battery connection points to prevent short circuits.

- Perchlorate materials

- This product contains one or more type CR lithium batteries. According to the state of California, CR lithium batteries are classified as perchlorate materials and require special handling. See www.dtsc.ca.gov/hazardouswaste/perchlorate for additional information.

Transporting batteries

The small lithium primary button cell contained in this equipment does not exceed 1 gram of lithium metal content per cell.

The small lithium-ion rechargeable battery that may also be packed with this equipment does not exceed a capacity of 100 Wh per battery or 20 Wh per component cell. Each battery type has been shown by the manufacturer to comply with the applicable requirements of the UN Manual of Tests and Criteria Part III, Subsection 38.3. Consult your carrier to determine which lithium battery transportation requirements are applicable to your configuration, including to its re-packaging and re-labeling, prior to reshipment of the product by any mode of transport.

If the instrument is being transported to Tektronix for service, remove the rechargeable batteries before repacking the instrument and do not include the batteries in the shipment. Do not ship removable batteries to Tektronix Service Centers.

Security disclaimer

This Software and its associated Equipment are not designed or intended to be used with unsecure networks. You acknowledge that use of the Equipment may rely upon certain networks, systems, and data communication mediums that are not controlled by Tektronix and that may be vulnerable to data or security breaches, including, without limitation, internet networks used by Your internet providers and the databases and servers controlled by Your internet providers. Tektronix shall not be liable for any such breaches, including without limitation, damages and/or loss of data related to any security breach, and disclaims all warranties, including any implied or express warranties that any content will be secure or not otherwise lost or altered.

For the avoidance of doubt, if You choose to connect this Software or Equipment to a network, it is Your sole responsibility to provide and continuously ensure a secure connection to that network. You agree to establish and maintain appropriate measures (e.g., firewalls, authentication measures, encryption, anti-virus applications, etc.) to protect the Software and Equipment and any associated data against security breaches including unauthorized access, destruction, use, modification, or disclosure.

Notwithstanding the foregoing, You shall not use any Products in a network with other products or services that are incompatible, insecure or not compliant with applicable laws.

Preface

This manual provides product safety and compliance information, describes how to connect and power on the oscilloscope, and introduces the instrument features, controls and basic operations. See the product Help document for more detailed information. Go to tek.com/warranty-status-search for warranty information.

MSO22 and MSO24 key features and benefits

- Bandwidths from 70 MHz to 500 MHz

- 2- and 4- analog channel inputs

- 10.1" TFT color (1280 x 800 pixels) Capacitive multi-touch display

- User interface optimized for touch screen use

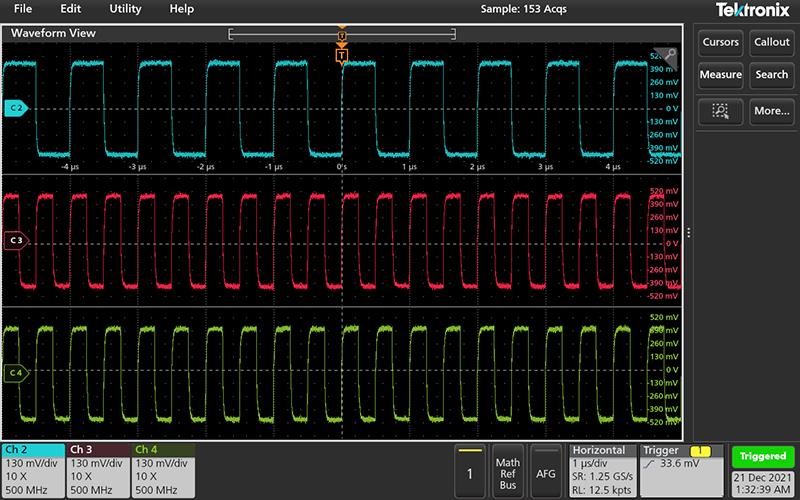

- 2.5 GS/s sample rate for half channels and 1.25 GS/s sample rate for all channels

- 10 M points record length on all channels

- Battery pack option includes 2 battery slots and hot-swap capability of the batteries within the battery pack module

- No set limit on the number of math, reference, and bus waveforms you can display (the number of waveforms depends on available system memory)

- Integrated options include 16 Channel MSO, 50 MHz Arbitrary Function Generator (AFG), 4 Bit Digital Pattern Generator, and trigger frequency counter

- Advanced serial bus triggering and analysis option lets you decode and trigger on industry standard buses

- Industry standard VESA interface can be used with several accessories offered by Tektronix and it is also compatible with off the shelf VESA mounts

Documentation

Review the following user documents before installing and using your instrument. These documents provide important operating information.

Product documentation

The following table lists the primary product specific documentation available for your product. These and other user documents are available for download from tek.com. Other information, such as demonstration guides, technical briefs, and application notes, can also be found at tek.com.

| Document | Content |

|---|---|

| Help | In-depth operating information for the product. Available from the Help button in the product UI and as a PDF on tek.com. |

| Quick Start User Manual | Introduction to product hardware and software, installation instructions, turn on, and basic operating information. |

| Specifications and Performance Verification Technical Reference | Instrument specifications and performance verification instructions for testing instrument performance. |

| Programmer Manual | Commands for remotely controlling the instrument. |

| Declassification and Security Instructions | Information about the location of memory in the instrument. Instructions for declassifying and sanitizing the instrument. |

| Service Manual | Replaceable parts list, theory of operations, and repair and replace procedures for servicing an instrument. |

| Upgrade Instructions | Product upgrade installation information. |

| Rackmount Kit Instructions | Installation information for assembling and mounting an instrument using a specific rackmount. |

How to find your product documentation

- Go to tek.com.

- Click Download in the green sidebar on the right side of the screen.

- Select Manuals as the Download Type, enter your product model, and click Search.

- View and download your product manuals. You can also click the Product Support Center and Learning Center links on the page for more documentation.

Install option upgrade licenses

Option license upgrades are field-installable licenses that you can purchase after receiving your instrument, to add features to your oscilloscope. You install option upgrades by installing license files on the oscilloscope. Each option requires a separate license file.

Before you begin

A node-locked license is valid only for the specific model number and serial number of the instrument for which it was purchased; it will not work on any other instrument. The single license file does not affect options that were factory installed or any other upgrades that you may have already purchased and installed.

About this task

| Note:You can only install a Node Locked option license one time. If you need to reinstall an uninstalled Node Locked license, contact Tektronix Customer Support. |

Procedure

- Follow the instructions you received to download the upgrade license file (<filename>.lic).

- Copy the license file or files to a USB memory device.

- Insert the USB drive into the powered-on oscilloscope for which the upgrade was purchased.

- Select Help > About.

- Select Install License to open the Browse License Files dialog box.

- Find and select the upgrade license file to install.

- Select Open. The oscilloscope installs the license and returns to the About screen. Verify that the installed license was added to the Installed Options list.

- Repeat steps 5 through 7 for each upgrade license file that you purchased and downloaded.

- Power cycle the oscilloscope to enable the installed upgrades.

- If you installed a bandwidth upgrade, rerun signal path compensation (SPC). Then carefully remove the model/bandwidth label from the lower-left corner of the front panel and install the new model/bandwidth label that was sent through normal mail channels as part of the upgrade purchase.

Check shipped accessories

Make sure that you received everything you ordered. If anything is missing, contact Tektronix Customer Support. In North America, call 1-800-833-9200. Worldwide, visit www.tek.com to find contacts in your area.

Check the packing list that came with your instrument to verify that you have received all standard accessories and ordered items. If you purchased factory installed options such as a Serial Bus and Triggering option, tap Help > About to confirm that the options are listed in the Installed Options table.

| Item | Quantity | Tektronix part number |

|---|---|---|

| Installation and Safety Manual | 1 | 071-3764-xx |

| TPP0200 200 MHz, 10x probe | One per channel | TPP0200 |

| Instrument stand | 1 | N/A |

| Power cord | 1 | Depends on region |

| Calibration certificate | 1 | N/A |

| Report of factory installed licenses | 1 | N/A |

Operating requirements

Use the instrument within the required operating temperature, power, altitude, and signal input voltage ranges to provide the most accurate measurements and safe instrument operation.

| Characteristic | Description |

|---|---|

| Temperature | Operating instrument: 0°C to +50°C (+32°F to 120°F), with 5 °C/minute maximum gradient, noncondensing (NC) |

| Operating with battery: 0 °C to 45 °C (+32 °F to 113 °F) | |

| For proper cooling, keep the rear of the instrument clear of obstructions for 2 inches (51 mm). | |

| Operating humidity | 5% to 90% relative humidity at temperatures up to +30°C, |

| 5% to 60% relative humidity at temperatures greater than +30°C and up to +50°C. | |

| Operating altitude | Up to 3000 meters (9842 feet) |

| Battery power | Requires 2-BATPK battery pack with 2 slots for batteries to be ordered with instrument or 2-BP battery pack with 2 slots for batteries to be ordered post instrument purchase |

| Supports up to 2 TEKBAT-XX Li-Ion rechargeable batteries. Operating time; Up to 3 hours single battery and up to 6 hours dual batteries. | |

| Tektronix recommends using the TEKCHG-XX external battery charger to charge the TEKBAT-XX batteries in ambient environments greater than +30°C. |

| Characteristic | Description |

|---|---|

| Power source voltage | 24 V DC |

| Power source current | 2.5 A |

Input signal requirements

Keep the input signals within allowed limits to ensure the most accurate measurements and prevent damage to the analog and digital probes or instrument.

Make sure that input signals connected to the instrument are within the following requirements.

| Input | Description |

|---|---|

| Analog input channels and AUX In, 1 MΩ setting, maximum input voltage at BNC | 300 VRMS |

| Measurement Category II | |

| Digital input channels, maximum input voltage range at digital inputs | Observe probe ratings |

| P6316 Logic Probe |

Check that the instrument passes power-on self tests

Power-on self tests verify that all instrument modules are working correctly after power up.

Procedure

- Power on the instrument and wait until the instrument screen appears.

- Select Utility > Self Test from the top-edge Menu bar to open the Self Test configuration menu.

- Check that the status of all power-on self tests are Passed.

- Power cycle the instrument.

- Select Utility > Self Test. If one or more power-on self tests still shows Failed, contact Tektronix Customer Support.

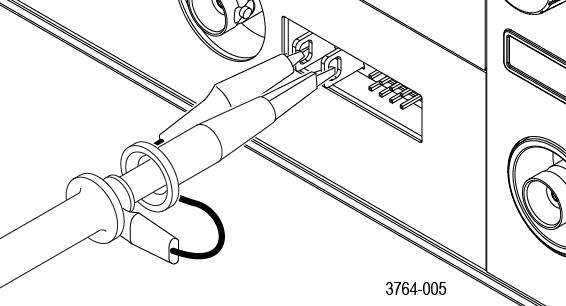

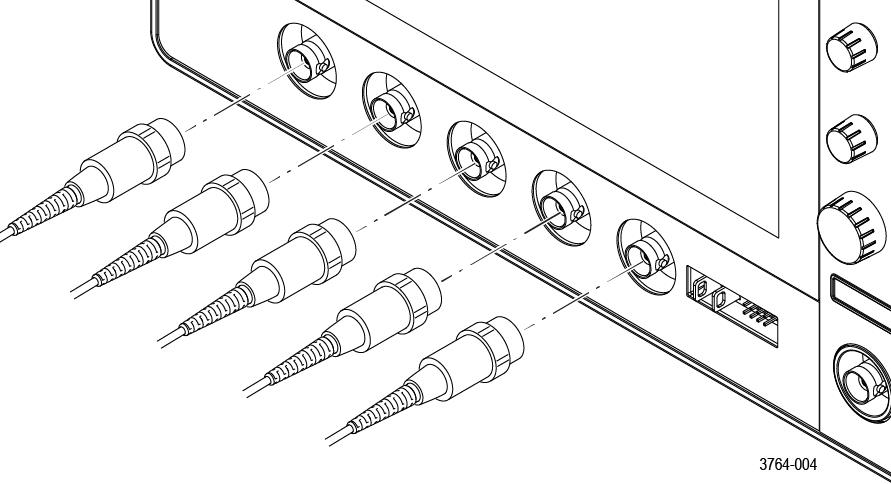

Connecting probes to the instrument

Probes connect the instrument to your device under test (DUT). Use a probe that best matches your signal measurement needs.

Connect a BNC passive probe or cable by pushing it onto a channel BNC bayonet connector and turn the lock mechanism clockwise until it locks.

Rackmount option information

An optional rackmount kit lets you install the oscilloscope in standard equipment racks.

Please refer to the product datasheet at tek.com for information on rackmount options.

Getting acquainted with your instrument

The following content provides a high-level description of the instrument controls and user interface. Refer to the instrument help for detailed information on using the controls and user interface to display waveforms and take measurements.

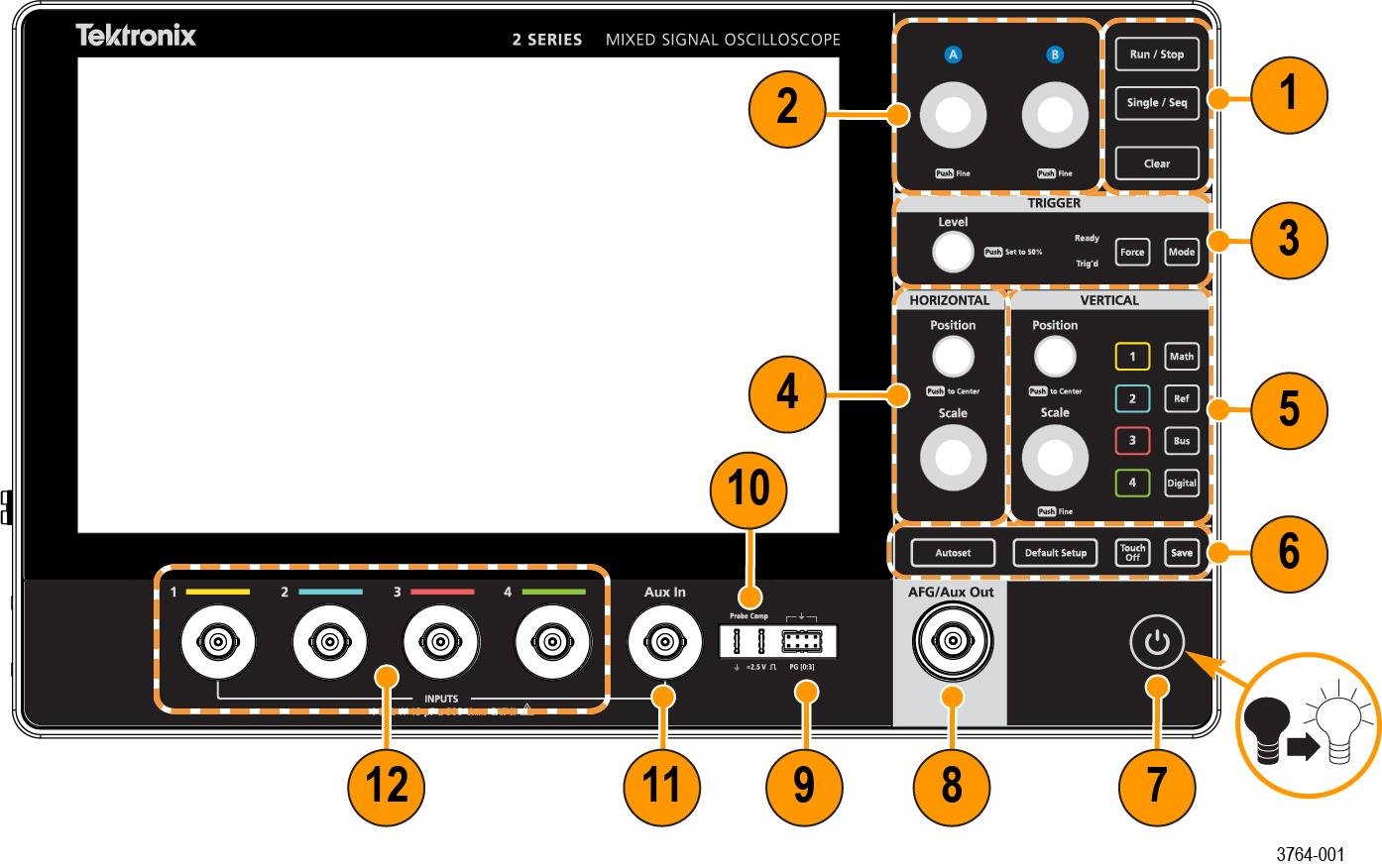

Front panel controls and connectors

The front panel controls provide direct access to key instrument settings such as vertical, horizontal, trigger, cursors, and zoom. The connectors are where you input signals with probes or cables.

| Description | |||

|---|---|---|---|

| 1 | Use the Acquisition controls to start and stop waveform acquisition, enable making a single waveform acquisition, calculate the average of all the samples for each acquisition interval, and delete the current acquisitions and measurement values from memory. | ||

| 2 | Use the Multipurpose Knobs (A, B) to move cursors, adjust the zoom, and set parameter values in configuration menu input fields. | ||

| 3 | Use the Trigger controls to force a trigger event at a random point in the waveform and capture the acquisition, set the amplitude level that the signal must pass through to be considered a valid transition, and set how the instrument behaves in the absence or presence of a trigger event. | ||

| 4 | Use the Horizontal controls to move the waveform from side to side on the screen, and set the time per major horizontal graticule division and samples/second parameters for the oscilloscope. | ||

| 5 | Use the Vertical controls to move the selected waveform up or down on the screen, set the amplitude units per vertical graticule division of the selected waveform, turn on (display) or select channels, and add or select a math, reference (saved), bus, and digital waveform on the Waveform view. | ||

| 6 | Use the Miscellaneous controls to turn touchscreen capability off, restore the oscilloscope settings to the default settings, automatically display a stable waveform, and save files or settings (using the current File > Save As settings). | ||

| 7 | After connecting the supplied power cord, use the power button to power the instrument on and off. The power button color indicates the following instrument states; amber is standby, blue is on, unlit is off. When the batteries in the 2-BP battery pack on your instrument have a low battery charge and the power cord is not connected, the power button will blink twice and then your instrument will turn off.

| ||

| 8 | The AFG/AUX Out BNC connector is multiplexed. You must select either AFG or Aux Out to use this connector. AFG is the signal output for the optional Arbitrary Function Generator (AFG) feature. AUX Out generates a signal transition on a trigger event or outputs a synchronization signal from the AFG. | ||

| 9 | Pattern Generator (PG) is a signal output for four Digital signals.

| ||

| 10 | Use Ground and probe compensation connectors to provide a ground connector to help reduce electrostatic damage (ESD) and adjust the high-frequency response of a passive probe. | ||

| 11 | Auxiliary trigger input (Aux in) is a connector to which you can connect an external trigger input signal. Use the Aux In trigger signal with the Edge trigger mode. | ||

| 12 | Use the Probe connectors to connect BNC passive probes and BNC cables. | ||

Button and knob functions

A description of the functionality of each button and knob on your instrument.

| Button | Description |

|---|---|

| Run/Stop | Starts and stops waveform acquisition. The button color indicates the acquisition status (green indicates running and acquiring; red indicates stopped). When stopped, the oscilloscope shows waveforms from the last completed acquisition. The Run/Stop button on the screen also shows the acquisition status. |

| Single/Seq | Enables making a single waveform acquisition, or a specified number of acquisitions (as set in the Acquisition configuration menu). Pushing Single/Seq turns off Run/Stop mode and takes a single acquisition. The button color indicates the acquisition status (quick green flash indicates single acquisition acquired; solid green indicates waiting for trigger event). Pushing Single/Seq again takes another single acquisition. |

| Clear | Deletes the current acquisitions and measurement values from memory. |

| A and B knobs | The multipurpose knobs A and B move cursors and set parameter values in configuration menu input fields. Selecting an menu field that can use a multipurpose knob assigns the indicated knob to change the value in that input field. The ring around each knob lights when you can use that knob to do an action. Push a multipurpose knob to enable the Fine mode for making smaller increment changes. Push the knob again to close Fine mode. |

| Force | Forces a trigger event at a random point in the waveform and captures the acquisition. |

| Level | Sets the amplitude level that the signal must pass through to be considered a valid transition. The color of the Level knob LED indicates the trigger source except for dual-level triggers. The Level knob is not available when the trigger type requires two level settings or other trigger qualifiers (set from the Trigger configuration menu). Push the knob to set the threshold level to 50% of the peak-to-peak amplitude range of the signal. |

| Mode | Sets how the instrument behaves in the absence or presence of a trigger event. |

| Auto trigger mode enables the instrument to acquire and display a waveform whether or not a trigger event occurs. If a trigger event occurs, the instrument displays a stable waveform. If a trigger event does not occur, the instrument forces a trigger event and acquisition and displays an unstable waveform. | |

| Normal trigger mode sets the instrument to acquire and display a waveform only when there is a valid trigger event. If no trigger occurs, the last waveform record acquired remains on the display. If no last waveform exists, no waveform is displayed. | |

| Horizontal Position | Moves the waveform and graticule side to side on the screen (changing the trigger point position in the waveform record). Push the knob to center the trigger event to the center graticule on the Waveform view. |

| Horizontal Scale | Sets the time per major horizontal graticule division and samples/second parameters for the oscilloscope. Scale applies to all waveforms. Push the knob to enable the Fine mode for making smaller increment changes. Push the knob again to close Fine mode. |

| Vertical Position | Moves the selected waveform (Channel, Math, Reference, Bus) and its graticule up or down on the screen. The color of the knob indicates which waveform the knob is controlling. Push the knob to set the threshold level to 50% of the peak-to-peak amplitude range of the signal. |

| Vertical Scale | Sets the amplitude units per vertical graticule division of the selected waveform. The scale values are shown on the right edge of the horizontal graticule lines, and are specific to the selected waveform in both Stacked or Overlay modes (in other words, each waveform has its own unique vertical graticule settings regardless of display mode). The color of the knob indicates which waveform the knob is controlling. |

| Channel buttons | Turn on (display), select, or turn off Channel, Math, Reference, or Bus waveforms. The number of channel buttons depends on the instrument model. If the channel is not displayed, pushing a Channel button turns on that channel to the Waveform view. If the channel is on the screen and is not selected, pushing that channel's button selects that channel. If the channel is on the screen and is also selected, pushing that channel's button turns that channel off (removes it from Waveform view). |

| Math | Adds or selects a Math waveform on the Waveform view. If no Math waveform exists, pushing the Math button adds a Math waveform to the Waveform view and opens the Math configuration menu. If only one Math waveform is displayed, pushing the button turns off the Math waveform (removes it from Waveform view). Push the button again to display the waveform. If two or more Math waveforms are displayed, pushing the button cycles through selecting each math waveform. |

| Ref | Adds or selects a Reference (saved) waveform on the Waveform view. If no Reference waveform exists, pushing the button opens the Browse Waveform Files configuration menu. Navigate to and select a waveform file (*.wfm) and tap Recall to load and display the reference waveform. If only one Reference waveform is displayed, pushing the button turns off the Reference waveform (removes it from the Waveform View). Push the button again to display the waveform. If two or more Reference waveforms are displayed, pushing the button cycles through selecting each Reference waveform. |

| Bus | Adds or selects a bus waveform on the Waveform view. If no Bus waveform exists, pushing the button adds a Bus waveform to the Waveform view and opens the Bus configuration menu. If only one Bus waveform is displayed, pushing the button turns off the Bus waveform (removes it from Waveform view). If two or more Bus waveforms are displayed, pushing the button cycles through selecting each Bus waveform. |

| Digital | Adds or selects a digital waveform on the Waveform view. If no digital waveform exists, pushing the button adds a digital waveform to the Waveform view and opens the digital configuration menu. If only one digital waveform is displayed, pushing the button turns off the digital waveform (removes it from Waveform view). If two or more digital waveforms are displayed, pushing the button cycles through selecting each digital waveform. |

| Autoset | Automatically displays a stable waveform. |

| Default Setup | Restores the oscilloscope settings (such as; horizontal, vertical, scale, position) to the factory default settings. |

| Touch Off | Turns touch screen capability off. The button is lighted when the touch screen is turned off. |

| Save | Save is a one-push save operation that uses the current File > Save As settings to save screen-shots (including open menus and dialog boxes), waveform files, instrument settings. If a File > Save or File > Save As operation has occurred since the last instrument start-up, pushing the button saves the file types to the location last set in the Save As configuration menu. If no file save operation has occurred since the last instrument start-up, pushing the button opens the Save As configuration menu. Select a tab to choose the type of file to save (such as; Screen Capture and Waveform), set any associated parameters, and where to save it, and select OK. The specified file or files are saved. The next time you push the button, the same type files are saved. Screen Captures save the entire screen, including most displayed configuration menus and dialog boxes. |

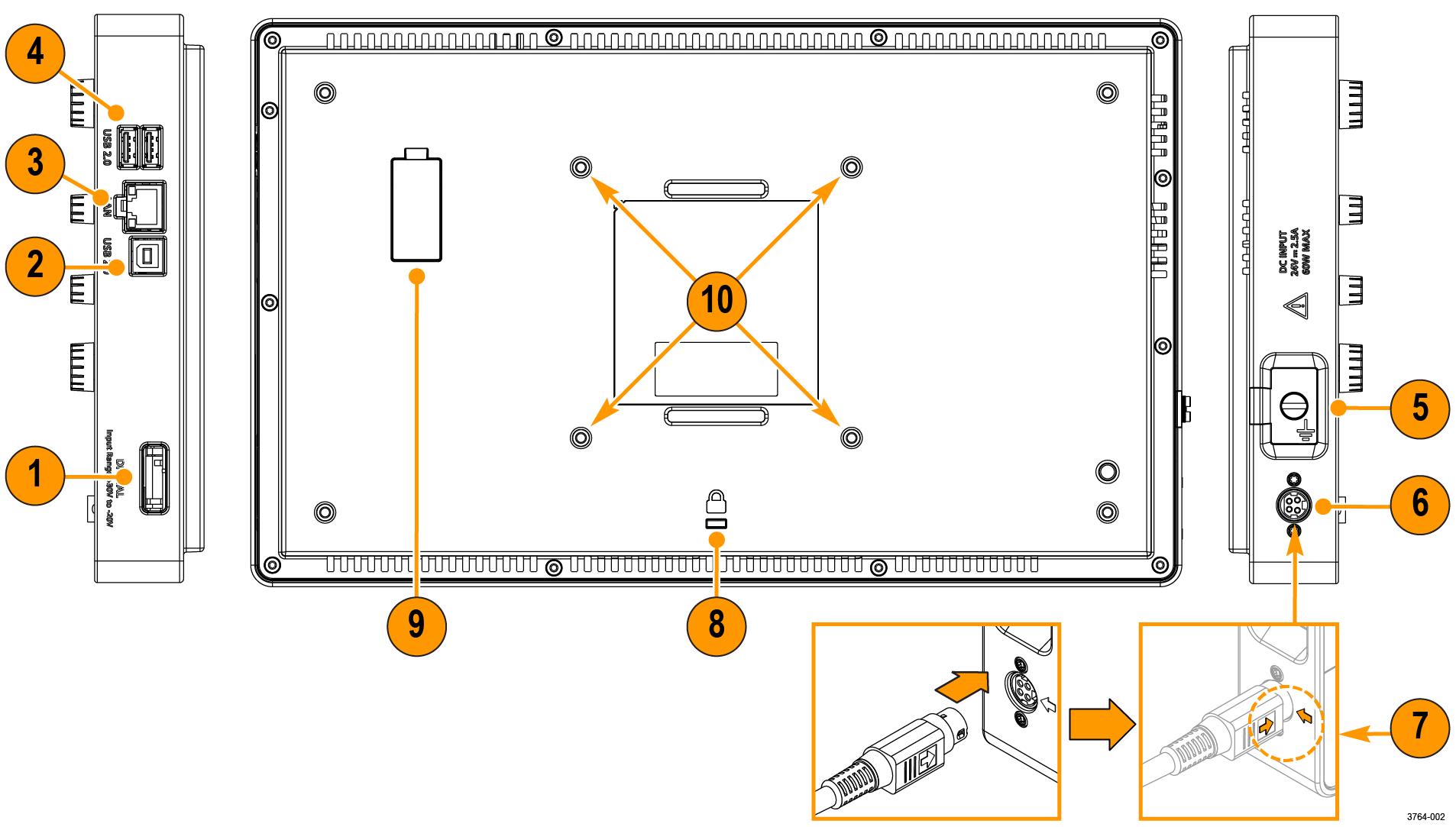

Rear and side panel connections

The rear and side panel connections supply power to the instrument and provide connectors for network, USB devices, digital probes, battery pack, and instrument stand.

| Description | |||

|---|---|---|---|

| 1 | Use the digital probe connector to connect the P6316 Logic Probe. | ||

| 2 | Use the USB Device port to connect to a PC to remotely control the oscilloscope using the USBTMC protocol. | ||

| 3 | Use the LAN connector (RJ-45) to connect the oscilloscope to a 10/100 Base-T local area network. | ||

| 4 | Use the two USB Host ports to connect a USB memory device, keyboard, or mouse | ||

| 5 | The ground lug external chassis ground point allows you to connect your instrument chassis to a ground reference. Use the ground lug when the instrument is operating on power from the optional battery pack accessory. Attach an anti-static wrist strap to the ground lug to reduce electrostatic damage (ESD) while you handle or probe the DUT. | ||

| 6 | To power the instrument, connect the supplied power cord to the power connector slot on the side of the instrument. Then connect the power cord to the appropriate AC mains source and use the power button. Use only the power cord specified for this product and certified for the country of use. To completely remove power from the instrument, disconnect the power cord. Use the power cord latch when removing the power cord from the power connector. | ||

| 7 | The power cord has a high force, latching connector to secure the power cord in place. Align the arrow on the latch with the arrow next to the connector. Push the latch in until the connector is fully seated. Hold onto the power cord latch and move it away from the power connector slot to disconnect the power cord. | ||

| 8 | Use the security lock connector to secure the oscilloscope to a work bench or other location with a standard PC/laptop lock cable. | ||

| 9 | Use the battery interface connector to connect the external battery pack to the instrument. See the instructions that come with the battery pack for more information.

| ||

| 10 | Use the VESA mount (100mm x 100mm) screws to mount your instrument to the supplied stand or other compatible VESA accessories. | ||

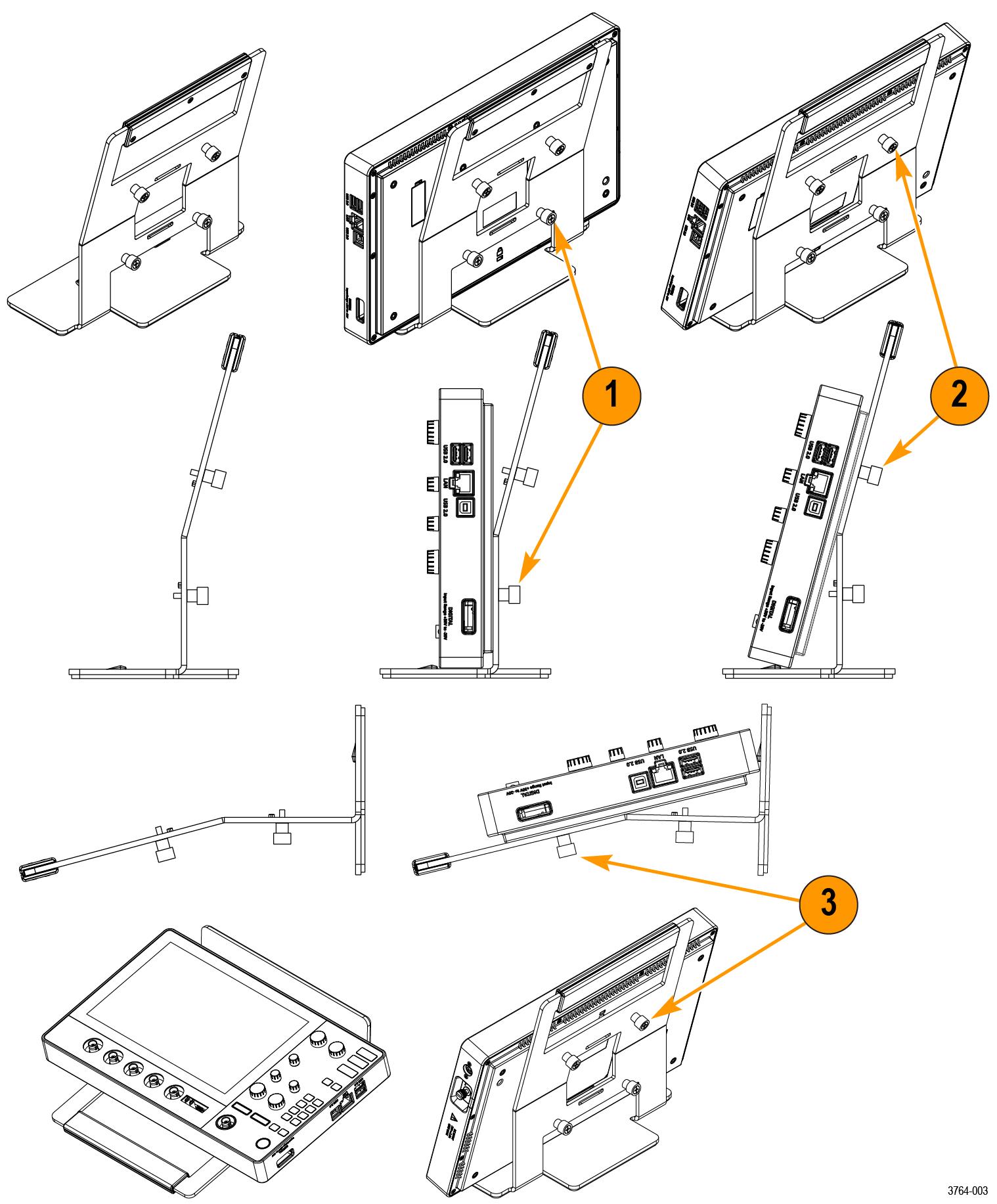

Instrument stand installation

Mount your instrument to the provided stand in three configurations.

Before you begin

Align the stand with the four VESA screw mounts (closest to the label) on the back of the instrument.

Procedure

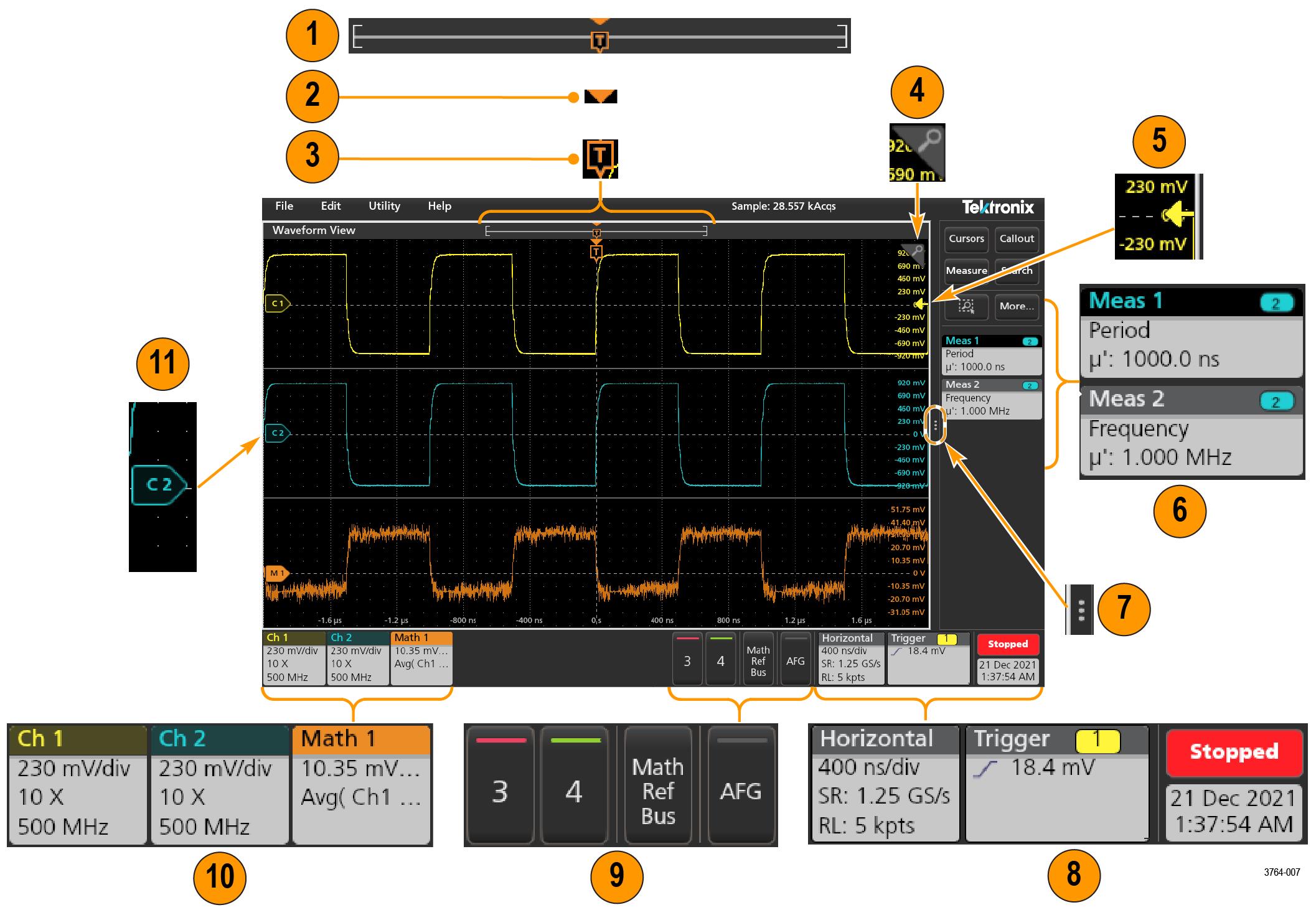

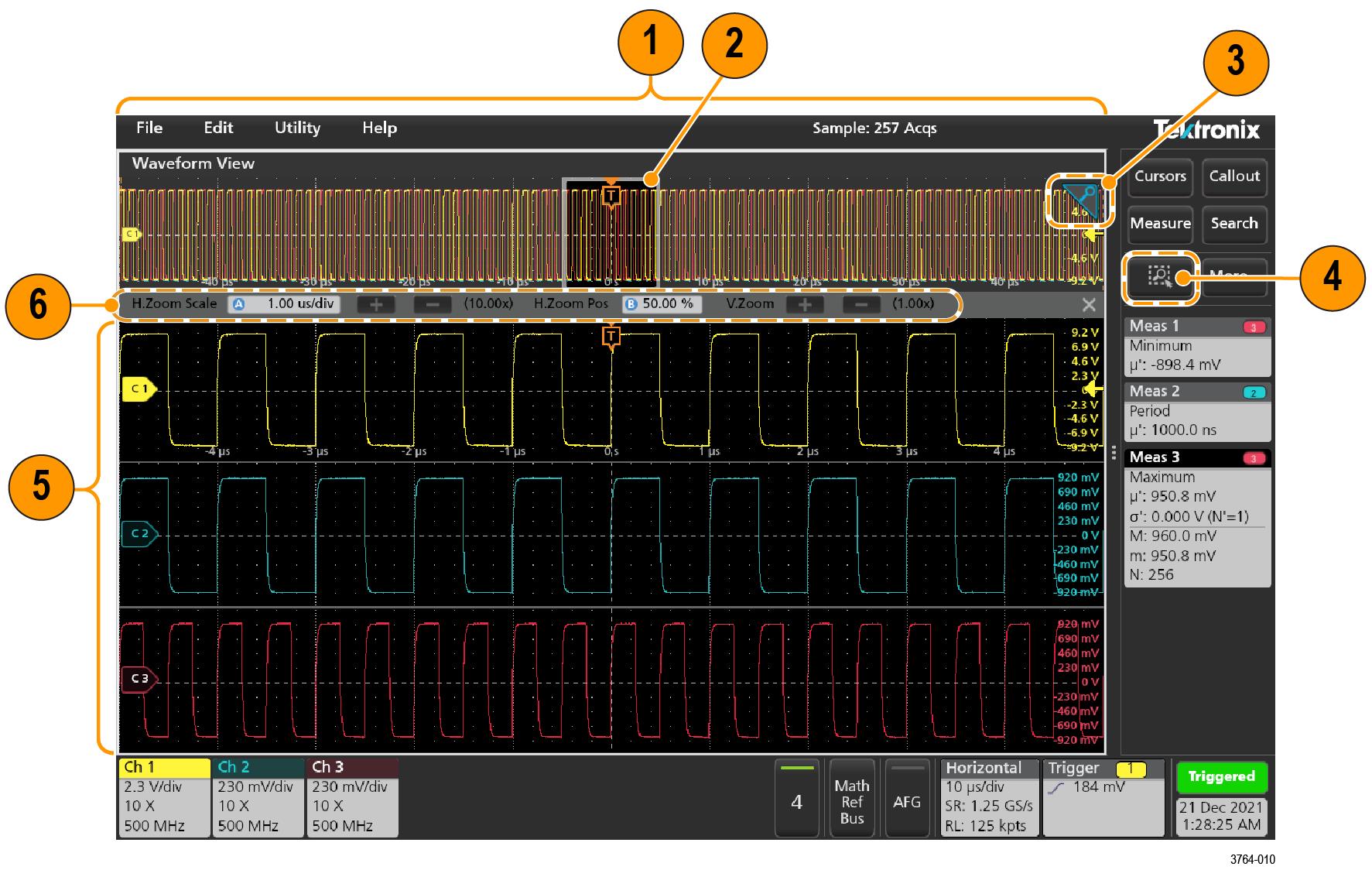

User interface

The touch screen user interface contains waveforms and plots, measurement readouts, and touch-based controls to access all oscilloscope functions.

| Description | |

|---|---|

| 1 | The menu bar provides menus for typical operations including: |

| Saving, loading, and accessing files | |

| Undoing or redoing an action | |

| Setting oscilloscope display and measurement preferences | |

| Configuring network access | |

| Running self tests | |

| Erasing measurement and settings memory | |

| Loading option licenses | |

| Opening a Help viewer | |

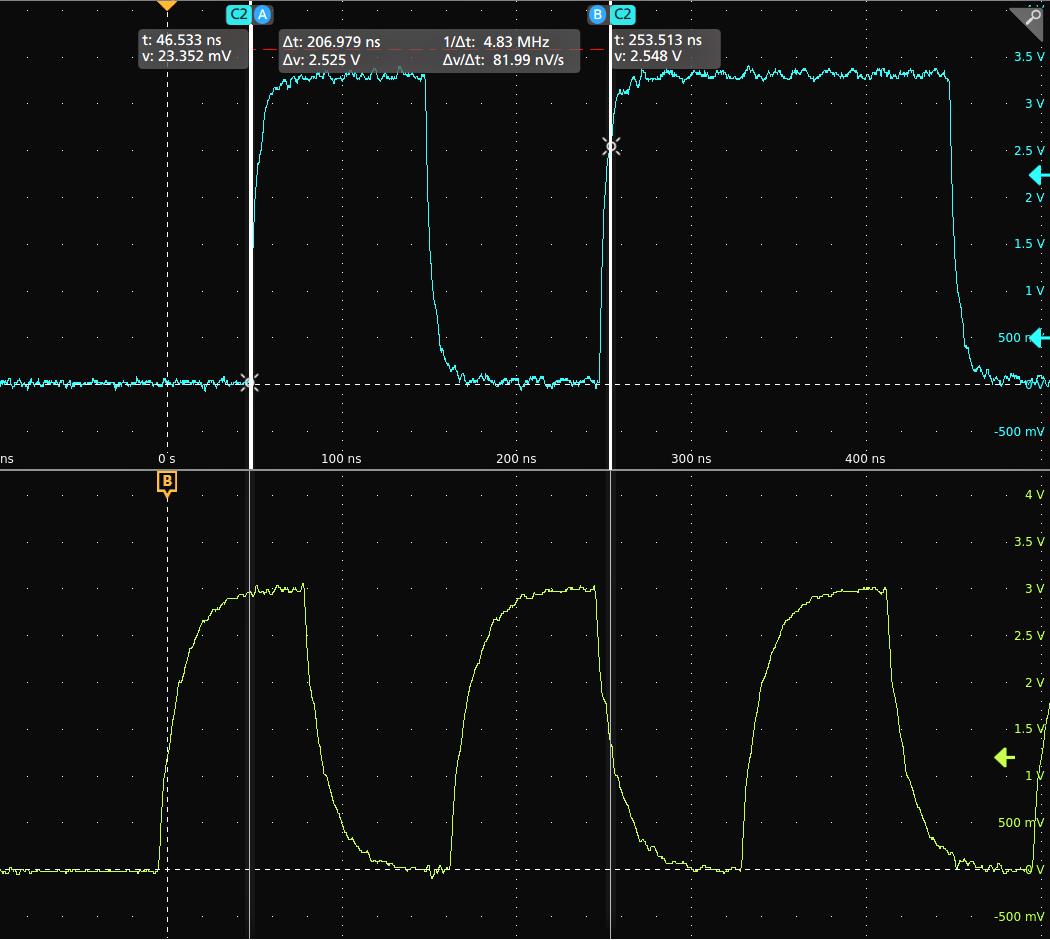

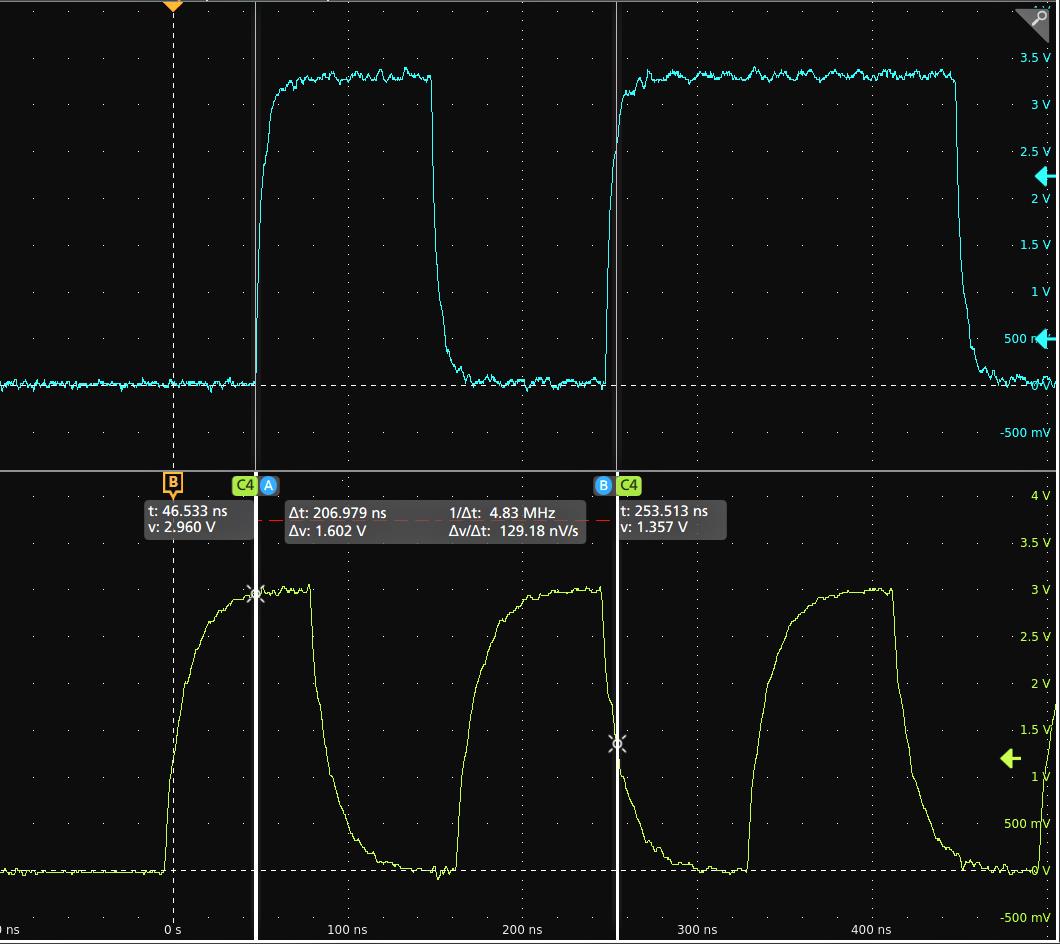

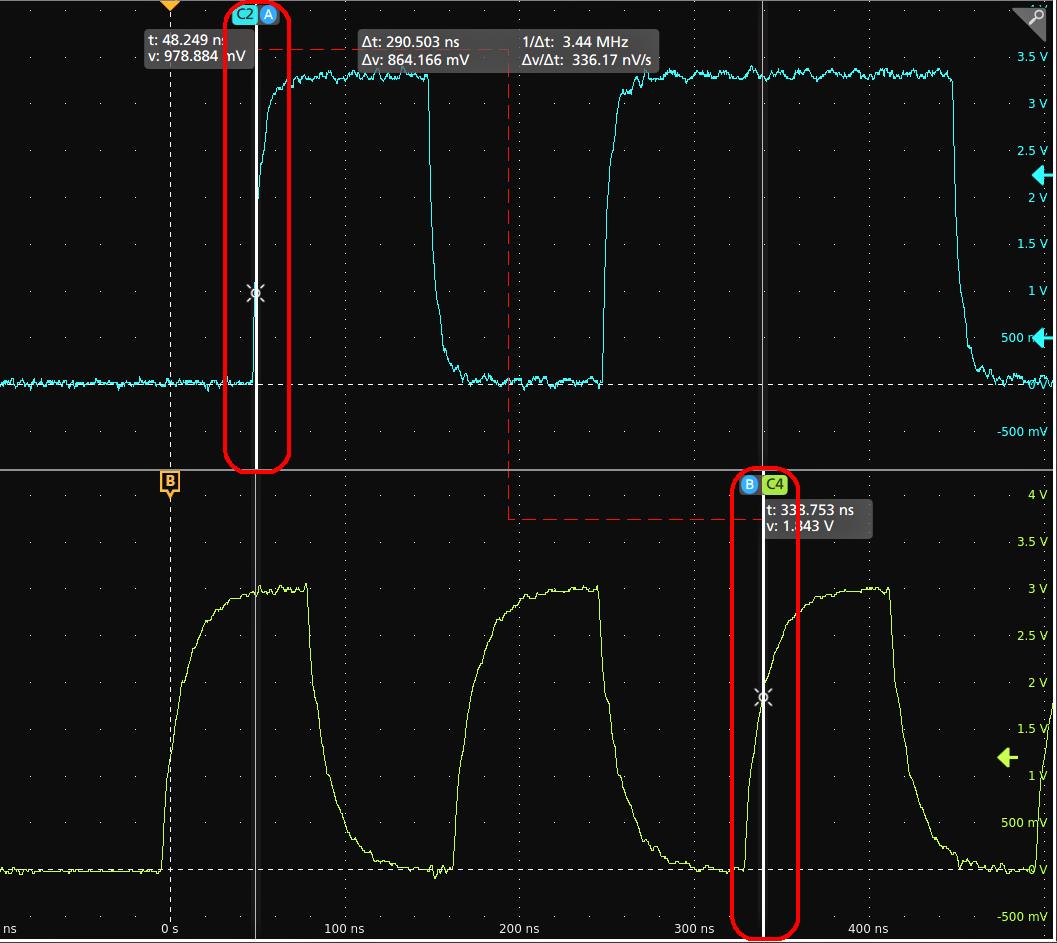

| 2 | The Waveform view area displays analog, digital, math, reference, bus, and trend waveforms. The waveforms include waveform handles (identifiers), individual vertical graticule scale labels, and trigger position and level indicators. You can set the Waveform View to stack each waveform vertically in separate graticule, called slices (the default mode), or overlay all the waveforms on the screen (traditional waveform view). You can also add Measurement Results views (plots) for individual measurements. These plot views are separate view windows that you can move on the screen by dragging their title bar to a new position. |

| 3 | The results bar contains controls for displaying cursors, adding callouts, plots, and result tables to the screen. You also are able to add badges to the results bar. To remove a measurement, search or other badge from the results bar flick-it off screen. The controls are: |

| The Cursors button displays on-screen cursors in the selected view. Touch and drag, or use the multipurpose knobs, to move the cursors. Double-tap on a cursor, or on the cursor readouts, to open a configuration menu to set cursor types and related functions. | |

| The Callout button adds a callout object to the selected view. Double-tap the callout text to open a configuration menu to change the type of callout, text and font characteristics. Drag any callout other than bookmark to any location on the oscilloscope screen view. Bookmarks callout can only be added to wave views and spectrum views. | |

| The Measure button opens a configuration menu from which to select and add measurements to the results bar. Each measurement you add has a separate badge. Double-tap a measurement badge to open its configuration menu. | |

| The Search button lets you detect and mark a waveform where specified events occur. Tap Search to open a configuration menu and set the search conditions for analog and digital channels. You can add any number of searches to the same waveform or to different waveforms. Search badges are added to the results bar. | |

| The zoom icon button at lets you to draw a box on the screen to zoom in on an area of interest, drawing segments for mask testing, or drawing areas to define visual trigger conditions. | |

| The More... button allows you to select Zoom and Mask. | |

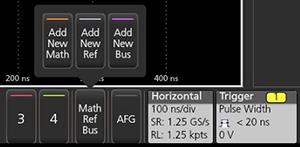

| 4 | The settings bar contains the following elements. Tap a channel or waveform button to add it to the screen and display a badge. Double-tap a badge to open its configuration menu. |

| System badges for setting Horizontal, Trigger, and Date/Time parameters | |

| Inactive Channel buttons to turn on channels | |

| Add New Waveform buttons to add math, reference, and bus waveforms to the display | |

| Channel and Waveform badges that let you configure the individual waveform parameters | |

| 5 | Configuration menus let you quickly change the parameters of the selected user interface item. You can open configuration menus by double-tapping on badges, screen objects, or screen areas. |

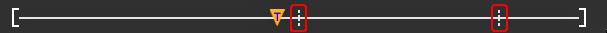

User interface elements

Each area of the user interface has a specific function that helps manage information or controls.

- The Waveform Record View is a graphical high-level view of the overall waveform record length, how much of the record is on the screen (shown in brackets), the location of key time events including the trigger event, and the current position of waveforms cursors. If you are displaying a Reference waveform that is shorter than the current acquisition record length, or you are changing the horizontal time scale while the oscilloscope acquisition is stopped, the brackets change position to show the part of the waveform record that is being viewed relative to the current acquisition total record length.

If cursors are active on a waveform, the Waveform Record View shows the relative cursor positions as small vertical dashed lines.

If cursors are active on a waveform, the Waveform Record View shows the relative cursor positions as small vertical dashed lines.

When in Zoom mode, the Waveform Record View is replaced with the Zoom Overview.

- The Expansion Point icon on the waveform view shows the center point around which the waveform expands and compresses when changing horizontal settings.

- The Trigger Position Indicator shows where the trigger event occurred in the waveform record. The trigger icon is displayed in the waveform slice that is the trigger source.

- The Zoom icon switches zoom on and off. The front panel Multipurpose knobs also turn on zoom mode and change the position and horizontal size of the Zoom Box.

- The Trigger Level Indicator icon shows the trigger level on the trigger source waveform. Some trigger types require two trigger levels.

- Measurement and Search badges show measurement and search results.

- The Results Bar Handle opens or closes the results bar, to maximize waveform screen viewing when needed. To reopen the results bar, either tap the handle icon or swipe left from the right side of the display.

- The System badges show global instrument settings (Horizontal, Trigger, Run/Stop status, and Date/Time).

- The Inactive Channel buttons add channel waveforms to the Waveform view and add an associated Channel badge to the Settings bar.

The optional AFG button opens the AFG configuration menu to set and enable the AFG output. This button is only present if the AFG option is installed.

The optional PG button opens the PG configuration menu to set and enable the PG output. This button is only present if the DPG option is installed.

The optional D15-D0 button opens the digital channel configuration menu to set and enable the digital channel. This button is only present if the 2-MSO option is installed.

- Double-tap a badge to open its associated configuration menu. If you add more Channel or Waveform badges than can fit in the waveform badge display area, tap the scroll buttons at each end of the waveform badge area to scroll and display hidden badges.

- The Waveform Handles on each waveform identify the source of that waveform (Cx for channels, Mx for Math waveforms, Rx for Reference waveforms, Bx for bus waveforms). The waveform handles are at the zero-volt level of the waveform by default. The currently selected waveform handle is a solid color; unselected waveform handles are outlined.

Double-tapping a waveform handle opens the configuration menu for that waveform.

For digital channels, the waveform handle shows the channel number. Each individual digital signal is labelled D0–D15 and is with a different color.

Double-tapping a digital waveform handle opens the digital channel configuration menu.

Dragging a digital signal handle over another handle swaps those two signals on the waveform.

Badges

Badges are rectangular icons that show waveform, measurement, and instrument settings or readouts. Badges also provide fast access to configuration menus. The badge types are Channel, Waveform, Measurement, Search, and System.

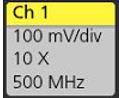

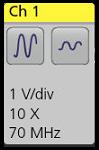

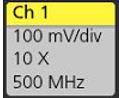

Channel and Waveform badges

You can drag Channel and Waveform badges to change their position in the Settings bar and open the badge right-click menu to access a quick-action menu.

- Right-click the badge and turn it off.

- Flick the badge off the bottom edge of the display to remove it from the Settings bar. Flicking upwards from the bottom edge of the Settings bar recovers the badge. Badge recovery is only possible within 10 seconds of removal.

Channel badges are listed in the channel order unless you have moved them. Channel badges may also display short error or warning messages. For more information double-tap the badge to open its configuration menu, or search the instrument Help.

Waveform badges (Math, Ref, Bus) are listed in the order created (unless they have been moved), and are grouped together by type. Deleting a Waveform badge does not change the order or names of the remaining badges.

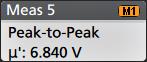

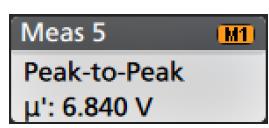

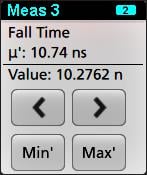

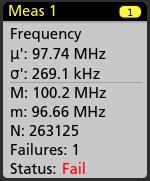

Measurement badges

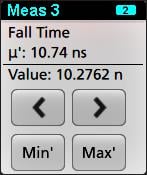

Double-tap a Measurement badge to open its configuration menu to change or refine settings. The default measurement badge readout shows the measurement's mean (μ) value.

To add statistical readouts to individual measurement badges, double-tap a measurement badge to open its configuration menu and select Show Statistics in Badge. The measurement badge displays the standard deviation (σ) value. The standard deviation is zero, when the population is one.

The < (Previous) and > (Next) buttons center the waveform in the display at the position of the previous or next measurement point in the record (for measurements that take more than one measurement per acquisition).

The Min' and Max' navigation buttons center the waveform in the display at the minimum or maximum value for that measurement in the current acquisition.

The prime symbol (') shown on measurement readings and Min/Max buttons indicates that the value shown (or moved to in the case of Min/Max buttons and waveforms) is from the current acquisition. Lack of a prime symbol means the value is from all acquisitions.

Measurement badges are listed in the order created, starting at the top of the Results bar. Deleting a Measurement badge does not change the order or names of the remaining badges.

You can drag Measurement badges to change their position in the Results bar and open the badge right-click menu to access a quick-action menu.

- Right-click the badge and turn it off.

- Flick the badge off the right edge of the display to remove it from the Results bar. Flicking left from the right edge of the Results bar recovers the badge. Badge recovery is only possible within 10 seconds of removal.

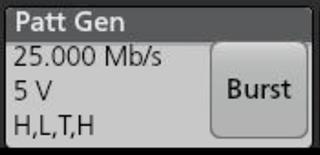

Pattern Generator badge

The pattern generator badge lists the bit rate, amplitude, and pattern definition. If the Pattern Definition is set to Manual, the badge shows the Bits 3 to 0. If Pattern Definition is set to File, the badge shows the file name. The Burst button displays in the badge when pattern generator Output is set to Burst.

To delete the pattern generator badge, right-click the badge and select Output > Off.

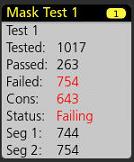

Mask Test badge

| Badge readout | Description |

|---|---|

| Label (optional readout) | A label defined in the badge configuration menu. |

| Tested | The total number of waveforms tested against the mask. |

| Passed | The number of waveforms that contained no samples that violated the mask. |

| Failed | The number of waveforms that contained one or more samples that violated the mask. Displays in red if greater than or equal to the total failures threshold. |

| Cons | The highest number of consecutively failed waveforms in the test run. Displays in red if greater than or equal to the consecutive failures threshold. |

| Status | The status of the mask test. It can be On, Off, Passed/Passing (green) or Failed/Failing (red). |

| Seg n (optional readout) | The number of waveforms that contained one or more samples that violated mask segment n. |

Double-tap a Mask Test badge to open its configuration menu to change or refine settings.

You can drag the badge to change its position in the Results bar and open the badge right-click menu to access a quick-action menu.

- Right-click the badge and turn it off.

- Flick the badge off the right edge of the display to remove it from the Results bar. Flicking left from the right edge of the Results bar recovers the badge. Badge recovery is only possible within 10 seconds of removal.

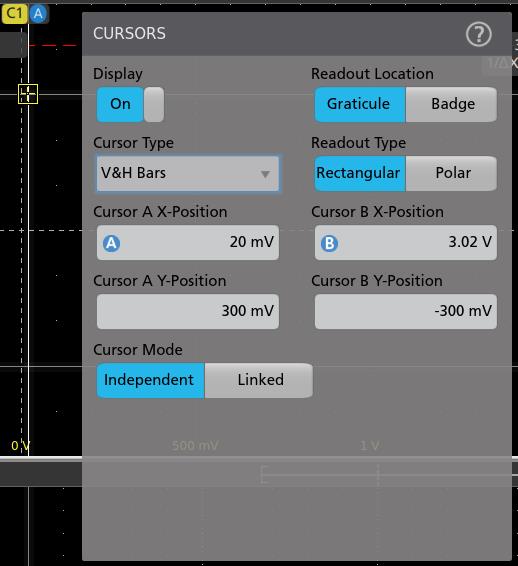

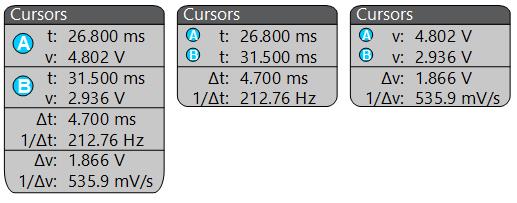

Cursor Badges

To create a cursor readouts badge, turn on Cursors, double-tap a cursor readout to open its configuration menu, and set the Readouts mode to Badge.

| Note:You can only view cursor readouts in one location at a time; either on the waveform or in a Cursors badge. You cannot move cursor readouts to a badge for Spectrum View cursors. |

You can drag the badge to change its position in the Results bar and open the badge right-click menu to access a quick-action menu.

- Right-click the badge and turn it off.

- Flick the badge off the right edge of the display to remove it from the Results bar. Flicking left from the right edge of the Results bar recovers the badge. Badge recovery is only possible within 10 seconds of removal.

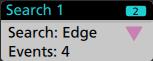

Search badges

Search badges are created by tapping the Search button. Use the displayed configuration menu to set the search criteria.

Some searches also provide Min and Max navigation buttons that open the Zoom mode and center the waveform in the display at the minimum or maximum value for that search event in the current acquisition.

Search badges are listed in the order created. Deleting a Search badge does not change the order or names of the remaining badges.

You can drag Search badges to change their position in the Results bar and open the badge right-click menu to access a quick-action menu.

- Right-click the badge and turn it off.

- Flick the badge off the right edge of the display to remove it from the Results bar. Flicking left from the right edge of the Results bar recovers the badge. Badge recovery is only possible within 10 seconds of removal.

Deleting mass Measurements/Searches badges at once

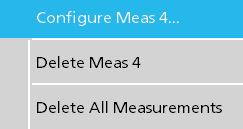

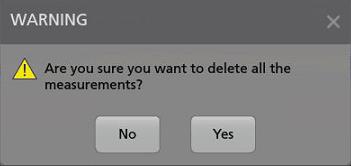

- Select and right click on the Measurement/Search badge in the Results bar, which displays the dialog box as shown:

Controls Description Configure Measurement/Search Configure Measurement or Search badges Delete Measurement/Search Deletes the selected Measurement (standard, power, etc.)/Search badge in the Results bar. Delete All Measurement/Search Deletes all the Measurement (standard, power, etc.)/Search badges in the Results bar. - When Delete All Measurements is selected, the oscilloscope asks for the confirmation to delete all the measurements/search at a time.

- The dialog box provides you a checkbox that gives the choice to bypass remaining information dialogs.

- Don’t ask for remaining items: Default is unchecked. If you leave it unchecked and clear the information dialog, then the dialog will appear again for the next measurement deletion.

- If the box is checked, it proceeds with deleting the rest of the items without bringing up the dialog box again. The dialog box appears for each set of measurements you want to delete.

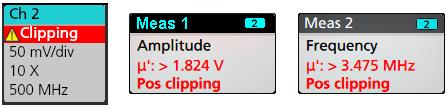

Signal Clipping and Badges

| WARNING:Clipping is caused by excessive or dangerous voltage at the probe tip, and/or a vertical scale setting that is not adequate to display the entire vertical range of the waveform. Excessive voltage at the probe tip can injure the operator and cause damage to the probe and/or instrument. |

To close the clipping message, change the vertical scale to show the entire waveform, disconnect the probe tip from the excessive voltage source, and check that you are probing the correct signal using the correct probe.

Clipping causes inaccurate amplitude-related measurement results. Clipping also causes inaccurate amplitude values in saved waveform files. If a math waveform is clipped, it will not affect amplitude measurements on that math waveform.

System badges

System badges (in the settings bar) display the main Horizontal and Trigger settings. You cannot delete System badges.

Double-tap a System badge to open its configuration menu.

The Horizontal badge also has Scale buttons, shown by single-tapping the badge. Use the Horizontal Scale buttons to increase or decrease the horizontal time setting.

Common badge actions

| Action | Result | Example |

|---|---|---|

| Single tap | Immediate access controls (Scale, Navigation). |

|

| Double tap | Configuration menu with access to all settings for the badge. |

|

| Touch and hold | Right-click menu with single tap access to common actions. Typical actions include turning off a channel and deleting a measurement or search badge. |  |

| Flick | Flick the badge off the bottom edge of the display to remove it from the Settings bar. Flick the badge off the right edge of the display to remove it from the Results bar. Flick from the right or bottom edge to recover a removed badge. This action is only possible within 10 seconds of badge removal. | |

Badge selection status

The appearance of a badge indicates its selection status (selected or unselected), or if a measurement needs to be deleted to close a channel or waveform badge.| Badge type | Selected | Unselected | Turned off or in use |

|---|---|---|---|

| Channel or Waveform |

|

|  |

| Measurement |  | N/A |

A dimmed Channel badge means the screen waveform is turned off (but not deleted). A dimmed Waveform badge means that the waveform display is turned off, or it is being used as a source by a measurement and cannot be deleted until the measurement is deleted.

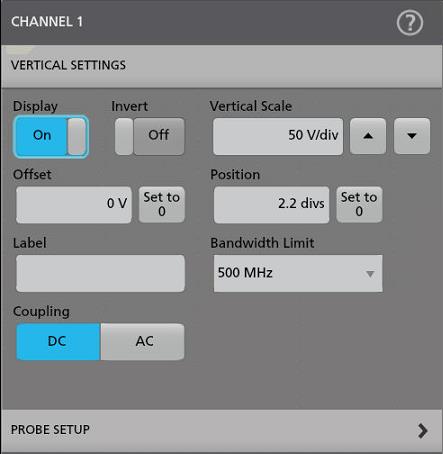

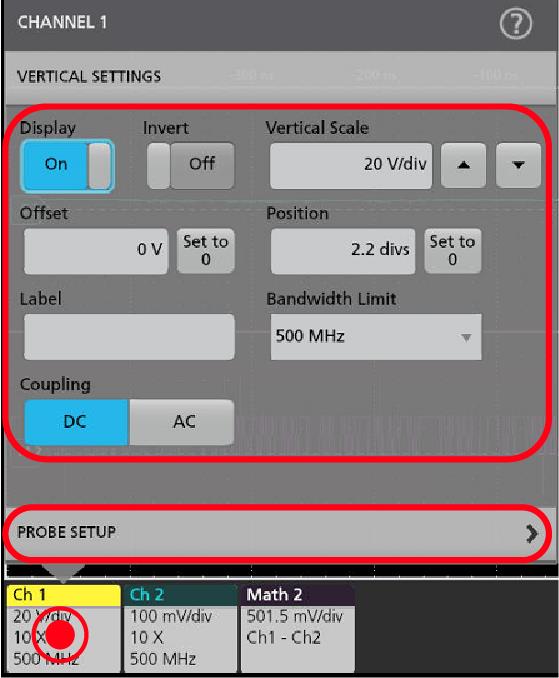

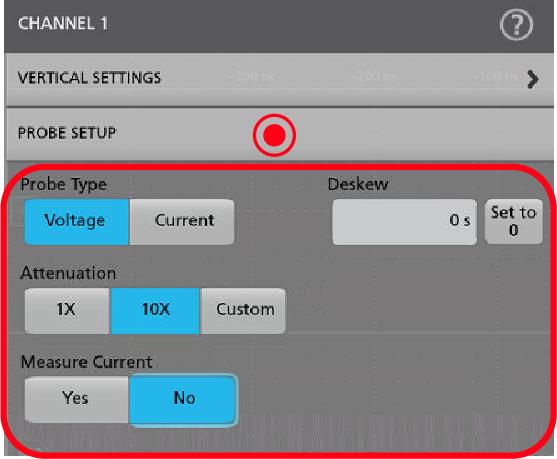

Configuration menus

Configuration menus let you quickly set the parameters for channels, system settings (Horizontal, Trigger), measurements, cursor readouts, Waveform and Plot views, callout text, and so on.

Selections or values that you enter take effect immediately. Menu contents are dynamic, and can change depending on your selections, instrument options, or attached probes.

Tap anywhere outside a configuration menu to close it.

To open Help content for a configuration menu, tap the question mark icon in the upper right corner of the menu.

Zoom user interface

Use the zoom tools to magnify waveforms to view signal details.

- The Zoom Overview shows the entire waveform record. All waveforms are shown in Overlay mode in the Zoom Overview area. Using pinch and expand gestures on the Zoom Overview waveforms changes the horizontal time base settings.

- The Zoom Box shows the area of the Zoom Overview to display in the Zoom View (see 5). You can touch and drag the box to move the area to view. Moving the Zoom Box, or changing its position, does not change the horizontal time base settings.

- The Zoom icon (in the upper right corner of the Waveform View) switches zoom mode on and off.

A zoom box lets you quickly draw a box around an area of interest in the Waveform or Zoom Overview. Drawing a box immediately puts the oscilloscope into zoom mode. To draw a zoom box, tap the DRAW-A-BOX button (while in Zoom mode), then touch and drag on the waveform to draw a box waveform. You can continue to draw zoom boxes until you single tap anywhere on the screen or open a menu.

To toggle between Zoom mode and Mask mode, double-tap the DRAW-A-BOX button and select one of the two options. Search for the Mask Testing topics in the oscilloscope Help for more information.

- The Zoom View shows the zoomed waveforms, as marked by the Zoom Box, in the Zoom Waveform Record View. Use pinch and/or drag options in the zoom view to change the zoomed area of interest. Pinch, expand, and drag gestures in the Zoom View only change zoom magnification settings and Zoom Box position.

- Use the Zoom Title Bar controls to adjust the vertical and horizontal size of the zoom area. Click or tap the + or - buttons or use the A and B multipurpose knobs.

In a waveform view, if both Cursor and Zoom are turned on, use the Zoom Box and Cursors button to change the multipurpose knob functionality. Tap the Zoom Title Bar to assign the knobs to adjust the zoom or tap the Cursors button to assign knobs to adjust the cursors.

Double tap the Horizontal Zoom Position or Horizontal Zoom Scale fields to enter a value using a numerical keypad.

To exit the zoom display mode, tap the Zoom icon in the corner of display or tap the X in the Zoom Title Bar.

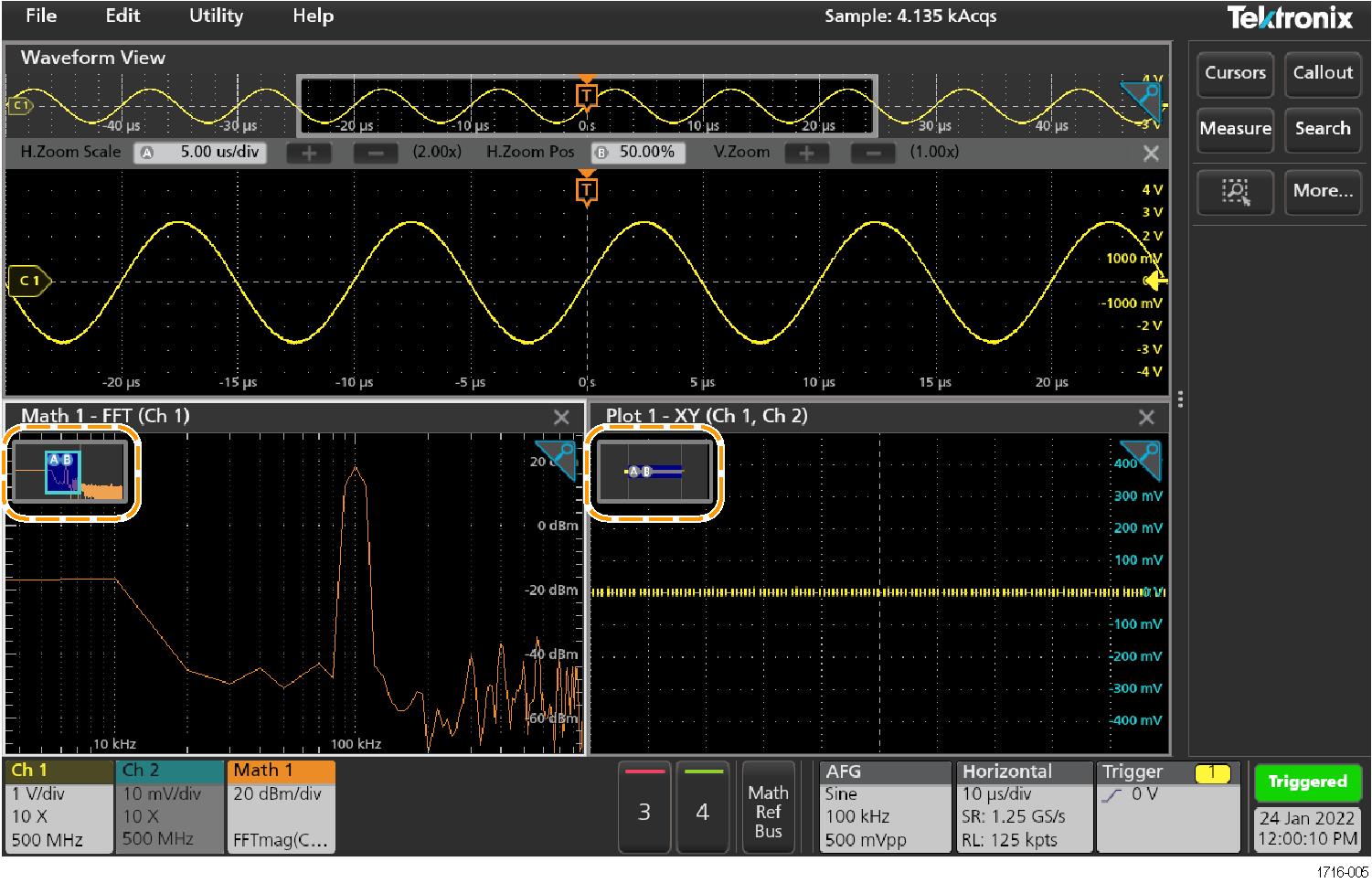

Math-FFT or XY plot view zoom

Use the A and B multipurpose knobs to adjust the zoom for Math-FFT or XY plot view.

If both Cursors and Zoom are turned on in Math-FFT or XY Plot view, use the Zoom Box and Cursors button to change the multipurpose knob functionality. Tap the Zoom Box to assign the knobs to adjust zoom or tap the Cursors button to assign knobs to adjust the cursors .

To exit the zoom display mode, tap the Zoom icon in the corner of view or tap the X in the Math-FFT view or XY plot view.

Using the touch screen interface for common tasks

Use standard touch screen actions, similar to those found on smart phones and tablets, to interact with most screen objects. You can also use a mouse to interact with the UI. The equivalent mouse operation is shown for each touch operation.

The oscilloscope has a user interface tutorial. Tap Help > User Interface Tutorial to quickly learn the fundamental touch operations.

| Task | Touchscreen UI action | Mouse action |

|---|---|---|

| Add a channel, math, reference, or bus waveform to the screen. | Tap an inactive channel button, Add New Math, Add New Reference, or Add New Bus button. | Click an inactive channel button, Add New Math, Add New Reference, or Add New Bus button. |

| Select a channel, math, reference, or bus waveform to make it active | Stacked or Overlay mode: Tap the Channel or Waveform badge. | Stacked or Overlay mode: Left-click the Channel or Waveform badge. |

| Stacked mode: Tap the channel, math, reference, or bus waveform slice or handle. | Stacked mode: Left-click the channel, math, reference, or bus waveform slice or handle. | |

| Overlay mode: Tap the channel or waveform handle. | Overlay mode: Left-click the channel or waveform handle. | |

| Display scale or navigation buttons on a badge (waveform, measurement, search, horizontal). Not all measurement or search badges display navigation buttons. | Tap the badge. | Click the badge. |

| Open a configuration menu on any item (all badges, views, cursor readouts, labels, and so on). | Double-tap the badge, view, or other object. | Double-click the badge, view, or other object. |

| Open a right-click menu (badges, views). | Touch and hold on the badge, Waveform View, Plot view, or other screen item until a menu opens. | Right-click the object. |

| Close a configuration menu. Some dialog boxes will not close until you click an OK, Close, or other button in the dialog. | Tap anywhere outside the menu or dialog. | Click anywhere outside the menu or dialog. |

| Move a menu. | Touch and hold the menu title bar or a blank area in the menu, then drag the menu to new position. | Click and hold the right mouse button on title or blank area, drag to new position. |

| Move a callout. Callouts are screen objects and are not associated with any particular waveform channel or slice. | Touch and hold on a callout and quickly start to drag, then move to new position. Start to move the callout as soon as selected (highlighted), otherwise the UI opens the right-click menu. | Click and hold the right mouse button on the callout and quickly start to drag, then move to the new position. |

| Change horizontal or vertical settings directly on a waveform. Vertical changes only apply to the selected channel or waveform; horizontal changes apply to all channels and waveforms. | Tap a badge and use the Scale buttons. | Left-click a channel, waveform, or Horizontal badge and click on the Scale buttons. |

| Touch and hold two fingertips on the waveform view, move them together or apart vertically or horizontally, lift from screen; repeat. | ||

| Increase or decrease the zoom area while in Zoom mode. | Touch and hold two fingertips on the waveform view, move them together or apart vertically or horizontally, lift from screen; repeat. | Click the + or - buttons on the Zoom Title bar. |

| Click the Draw-a-Box button, draw a box around the waveform area of interest. | ||

| Quickly scroll or pan a waveform or list. | Touch and drag in the waveform or list. | Click and drag in the waveform or list. |

| Close or open the Results Bar to increase the Waveform View area. | Tap on the Results Bar Handle (three vertical dots in border) or anywhere in the border between the Waveform View and the Results Bar. | Click the Results Bar Handle (three vertical dots in border) or anywhere in the border between the Waveform View and the Results Bar. |

| Click and drag the Results Bar divider. | ||

| Change the position of badges in the Settings Bar or Results Bar. | Touch and drag the badge to a new position in the same bar. | Click and drag the badge to a new position in the same bar. |

Configure the instrument

Configurations to help operate your instrument efficiently. Refer to the instrument help for additional configuration information.

Download and install the latest instrument firmware

Installing the latest firmware helps ensure that your instrument has the latest features and is taking the most accurate measurements.

Before you begin

Save any important on-instrument files such as waveforms, screen captures, and setups to a USB drive or network. The installation process does not remove user-created files, but it is recommended to back up important files before an update.

Determine the current version of firmware installed on the instrument using the Help > About menu.

Procedure

What to do next

To confirm the firmware update, locate the version number found in the About window under the Help menu. Confirm that the instrument firmware version number matches the firmware version number that you just installed.

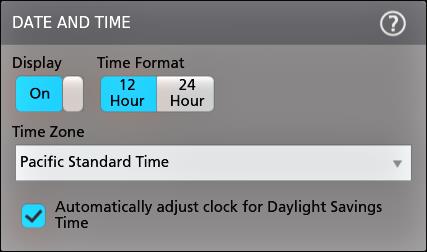

Set the time zone and clock readout format

Set the time zone to your region so that saved files are marked with the correct date and time information. You can also set the time format (12 or 24 hour clock).

Procedure

Run Signal Path Compensation (SPC)

Run SPC when you first receive an instrument, and at regular intervals, for best measurement accuracy. You should run SPC whenever the ambient (room) temperature has changed by more than 5 °C (9 °F), or once a week if you use vertical scale settings of 5 mV per division or less.

About this task

Signal Path Compensation (SPC) corrects for DC level inaccuracies in the internal signal path, caused by temperature variations and/or long-term signal path drift. Failure to run SPC on a regular basis may result in the instrument not meeting warranted performance levels at low volts per division settings.

Before you begin

Disconnect all probes and cables from the front-panel channel inputs and rear-panel signal connectors.

Procedure

Compensate the probe

Probe compensation adjusts the high frequency response of a probe for best waveform capture and measurement accuracy. Use this procedure to adjust probe compensation for probes with a manual adjustment.

The following procedure checks the probe compensation.

- Connect a supported probe to Channel 1.

- Connect the probe tip and ground lead of the probe to the PROBE COMP terminals. Connect only one probe at a time to the PROBE COMP terminals.

- Turn on the Channel 1 and turn off all other channels.

- Tap File > Default Setup.

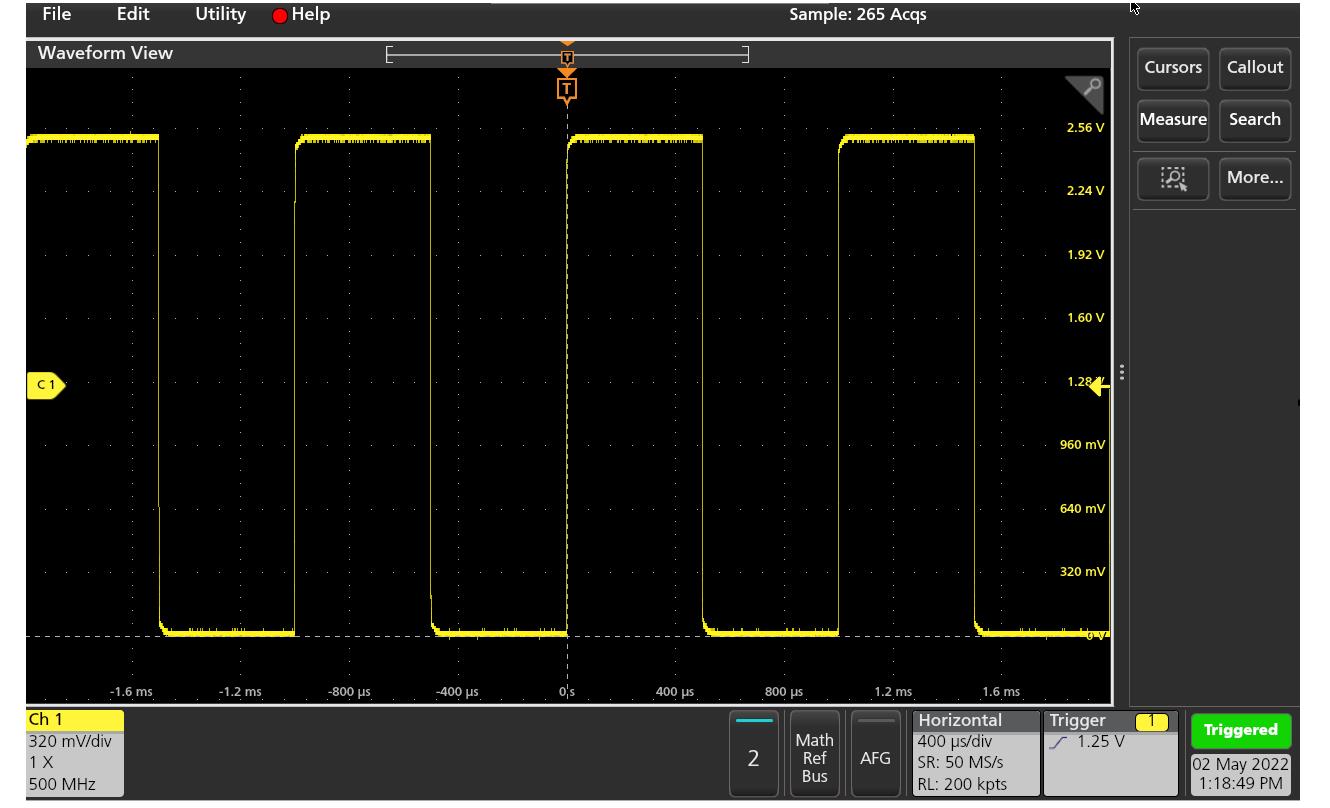

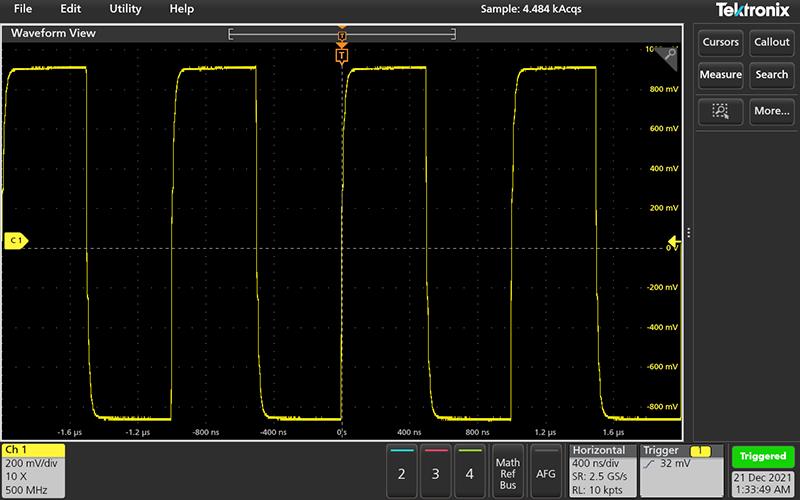

- Push the Autoset button on the front-panel or tap File > Autoset from the menu bar. The screen should display a square wave with the levels between approximately 0 V - 2.5 V and 1 kHz.

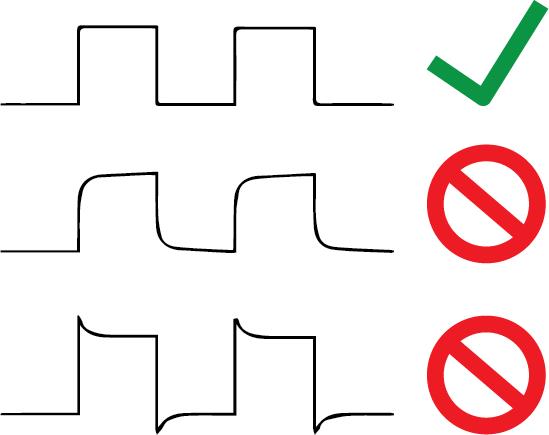

- Check the shape of the displayed waveform to determine if the probe needs adjusted. If the waveform has a square leading edge and a flat top and bottom, the probe does not need adjusted. If the waveform leading edge is rounded or has a spike, you need to adjust the probe compensation.

- Use the probe adjustment tool provided with the probe to adjust the probe until the waveform has as flat a top and bottom as possible. Remove the adjustment tool before looking at the waveform. Repeat until waveform top and bottom are flat. See your probe manual for adjustment location and instructions.

- Repeat these steps for each probe connected to each channel. You must run this procedure every time you move a probe from one channel to another.

Connect to a network (LAN)

Connecting to a network allows you to remotely access the instrument.

Work with your network administrator to obtain the required information to connect to your network (IP address, Gateway IP address, Subnet Mask, DNS IP address, and so on).

- Connect a CAT5 cable from the instrument LAN connector to your network.

- Select Utility > I/O on the menu bar to open the I/O configuration menu.

- Obtain or enter the network address information:

- If your network is DHCP-enabled, and the IP address field does not already show an address, tap Auto to obtain the IP address information from the network. DHCP mode is the default mode.

- If your network is not DHCP-enabled, or you need a permanent (non-changing) IP address for this instrument, tap Manual and enter the IP address and other values provided by your IT or system administrator resource.

- Tap Test Connection to verify that the network connection is working. The LAN Status icon turns green when the instrument successfully connects to your network. If you have problems connecting to your network, contact your system administration resource for help.

Connect the oscilloscope to a PC using a USB cable

Use a USB cable to connect the oscilloscope directly to a PC for remote instrument control.