Read previous blogs in this series exploring other automotive innovation trends driving the market:

Part 1: 3 Market Trends Driving Automotive Innovation – Part One: Electrification and Batteries

Part 2: 3 Market Trends Driving Automotive Innovation Part Two In-Vehicle Networking

Part 3: 3 Market Trends Driving Automotive Innovation – Part Three: The Autonomous Vehicle

At the heart of the automotive industry’s technological innovation are three market trends – electrification and batteries, the connected car and its subsequent data, and automation. In a recent post, we tackled electrification and batteries and the key challenge of increasing capacity and range on a single charge. In this post, we’ll cover the connected car – specifically in-vehicle networking – that creates an autonomous datacenter on wheels. All of these trends are the focus of an on-demand webinar – The Future of Automotive is Electric – by Denis Solomon, Automotive Market Segment Manager here at Tektronix.

Automotive Connectivity and In-Vehicle Networking

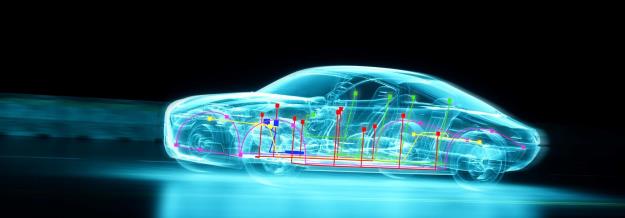

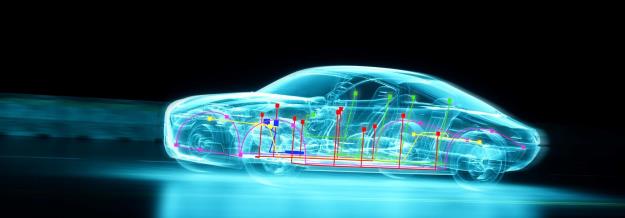

Today’s modern vehicle is more like a datacenter on wheels, with sensors everywhere feeding information back to a central computer. These sensors are typically connected over a CAN network, which is an internal, in-vehicle network. What is really important here is to ensure that the critical data for vehicle operations and safety, is given priority. You do not want your music system to cause traffic jams or block signals that are carrying critical information, for example, to the brakes.

The market trend in the connected car and subsequent data for the car is around consolidation of electronic control units (ECU). An ECU is a computer that talks with the sensors and acts on the instructions and the perceptions that the sensors are feeding back to it. The market trend here is to consolidate the number of ECUs, as a typical car has about 80 to 100 ECUs per vehicle. There is a movement towards going from domain to zonal and eventually to a central computer on the electronic architecture in the near future. There will be a lot of in-vehicle networking in the next generations that will evolve as we move towards a more connected and autonomous car.

The Benefits of ECU Consolidation

Just to provide some interesting data points… there are approximately 100 ECUs, and the wiring harness goes around and connects all of the different ECUs and sensors. It’s about eight kilometers long in a typical mid-sized car and weighs about 50 to 100 kilograms. There is a need to reduce this weight to improve the range of an electric vehicle as we discussed in our previous post. When we go from traditional internal combustion gas-powered vehicles to battery vehicles, the weight of the vehicle is crucial. Anything that we can do to improve this and squeeze out more performance from the battery pack can result in performance improvement.

The Challenge of Automotive Ethernet and its Data

Depending on the application, there is a need for different network standards to connect the ECUs and the sensor suites that are all around the car. As the number of in-vehicle standards grows, there will need to be better test methodologies and better testing tools to gain measurement insights faster. Compliance and system-level performance are critical. Time sensitivity is top of mind for auto makers and Tier 1 suppliers.

The Tektronix Role in Measurement

The physical layer is the base over which all these in vehicle network standards are being run. For the protocol verification, the engineer needs to perform these physical layer tests like eye diagram, signal quality, signal jitter, EMI, EMC testing, to ensure that the networks are complying to the standards and can communicate and work reliably in the harsh automotive environment in real world.

Tektronix offers a comprehensive IVN solution portfolio, with coverage from the low-speed IVN standards all the way to high-speed, multi-gig Ethernet. In fact, Tektronix was first to market with our multi-gig automotive Ethernet compliance solution. We sit on standards bodies for Ethernet, like the OPEN Alliance TC 15 subcommittee, which defines these test specifications, as well as ASA. We are also actively contributing members on the IEEE specification for development of these in-vehicle networks to name a few.

On top of making sure that the silicon and the sensors are working per the standards, there is also a need for interoperability across devices. Standards help take care of that by making sure these devices are interoperable, but then you have compliance testing as well as protocol decoding and system-level performance testing for automotive internet. Tektronix offers the most comprehensive solutions, and there is a relatively new Ethernet communication that is a bidirectional, full-duplex signal. Tektronix came up with a software solution to separate the signals in a full duplex Ethernet channel. The previous approach required cutting the cable – basically introducing a new h/w directional coupler to make these measurements. With Tektronix’s software-based, patented approach of signal separation, we can now do these signal measurements for Ethernet in a non-intrusive way – without cutting a cable and without loading a system with additional h/w. Making these measurements for system-level testing easier improves time to market and confidence in measurements for our Tier One suppliers as well as OEMs and customers.

The last automotive innovation trend we’ll explore is automation – as in the autonomous vehicle – so watch for part three of this series soon.