お問い合わせ

ダウンロード

マニュアル、データシート、ソフトウェアなどのダウンロード:

フィードバック

Camera Measurements

VM700T Option 21

VM700T Option 21

Features & Benefits

- Significantly Simplifies Key Measurements of Camera Performance

- Compatible with NTSC or PAL

- Reduces Time Spent on Acceptance Testing, Routine Maintenance and Operational Adjustments

- Uses Industry Standard Charts

- Camera Matching Simplified with Relative-to-reference Mode

- Four Key Measurements:

- Colorimetry

- CCD Defects

- Fixed Pattern Noise

- Frequency Response

- Five Additional Measurements:

- Detail

- Gamma

- Geometry and Registration

- Shading

- Vertical Smear

Applications

- Pre-purchase Evaluation and Comparison of Cameras

- Acceptance Testing

- Camera Maintenance

- Camera Matching

- Camera Design

VM700T Option 21 Camera Measurements Package

The Tektronix VM700T Option 21 Camera Measurements package simplifies several key camera measurements for both tube and CCD television cameras. By automating measurement and characterization routines, the time consuming tasks of evaluating and comparing cameras become quick, objective and repeatable. Whether for pre-purchase evaluation, acceptance testing, routine maintenance or operational adjustments, Option 21 saves valuable time while providing the time-proven reliable digital measurements of the VM700T.

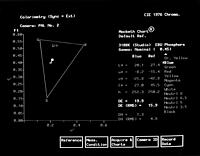

Colorimetry

The Colorimetry measurement evaluates a camera's ability to accurately reproduce color. For in-depth analysis, detailed information can be obtained from a graphical display of the camera's performance plotted on the CIE 1976 chromaticity diagram, which is accompanied by tabular data of CIELUV parameters. Two weighted RMS results provide an indication of a camera's overall performance. An alternative display offers the ability to continuously monitor the output while the camera is adjusted. This measurement allows the use of a Macbeth ColorChecker chart or a user-defined chart. Preset references are available with a Macbeth chart. Configure mode can be used to define a custom light source as well as custom color references.

CCD Defects measurement with single-line waveform display.

CCD Defects bar graph display.

CCD Defects

Defective pixels, or clusters of pixels, in the CCD create "holes" in the camera's video output. The CCD Defects Measurement maps defective pixels on a graphical representation of the CCD. Both negative and positive deviations in pixel charge can be detected when the measurement is performed at black (lens capped) and at a 50 IRE signal level. A variable threshold provides flexibility in tailoring the measurement to the requirements of individual applications. Defects can be scrutinized on a line-by-line basis with a waveform display below the map of defective pixels. A bar graph of defective pixel cluster size is also available.

Fixed Pattern Noise measurement with histogram.

Fixed Pattern Noise

The Fixed Pattern Noise measurement characterizes persistent current variations that correlate to CCD pixels. It is recommended the measurement be performed at black (lens capped) and at a 50 IRE signal level. Overall fixed pattern noise is indicated by a single result.

A histogram plots each pixel's deviation from the nominal current level. A threshold cursor on the histogram determines which pixels are mapped on a graphical representation of the CCD. An expand picture mode provides greater resolution for inspecting noise patterns. For further analysis, a single-line waveform display is available, as well as an alternate spectrum display.

Frequency Response and Aliasing

Degradation in waveform amplitude as a function of frequency is characterized by the Frequency Response measurement. Any multiburst squarewave or sinewave chart designed for frequency response testing with six to twelve packets can be used. Aliasing quantifies the aliasing phenomenon of the CCD image sampling process. The aliased components are measured in both amplitude and actual frequency represented. A multiburst sinewave chart is recommended for aliasing measurement. Results are displayed by one graph (Y channel of color difference signals) or three graphs (each channel of GBR signals). The out-of-band packets (<6 MHz) are used to measure aliasing.

Frequency Response measurement of a GBR signal.

Detail

To enhance an image, cameras have circuits that artificially sharpen the brightness transitions by adding a correction signal. This measurement quantifies the amount of correction and expresses it as a percentage of the transition amplitude. Both the horizontal and vertical detail are measured and the corresponding waveform is graphed. Although this measurement will accept any input signal, we recommend using the GBR signals to measure detail. Any chart that contains a white patch, such as a window chart or a gray scale chart with a white chip, can be used for the evaluation of detail.

Gamma

The Gamma application measures the input to output light transfer characteristic of the camera. This transfer function curve is plotted and the exponent of the curve (gamma) is the measured result. Shading errors can be accounted for during the measurement process and eliminated from the measured results. While this application will accept any signal, we recommend using GBR signals to quantify gamma. Either a linear or logarithmic gray scale chart can be used.

Geometry/Registration display.

Colorimetry Real-time display.

Geometry and Registration

Geometry measures, on the green channel, the geometric distortions that exist in the camera. How well the red and blue channels track the green channel is then expressed as registration error. In the VM700T, both geometry and registration can be measured using a standard or custom made registration chart. The error results are expressed as a percentage of picture height. The locations of the worst errors in each quadrant are clearly marked on the monitor-like display. Because errors closer to the center of the image are far more noticeable than errors towards the edges of the image, different zones can be plotted over the display to better evaluate the severity of the errors. These measurements can only be made with GBR input signals.

Aliasing display.

Shading

Both lens distortions and camera circuitry can cause a camera's output level to vary from one area to another within a field while the input light level is held constant. The signal level variation is measured both across lines (horizontal shading) and down fields (vertical shading). Both horizontal and vertical waveforms are displayed and the errors are expressed as a percentage of peak white.

A median filter can be applied to eliminate high frequency amplitude errors that may skew the measurement results. It is recommended that the measurement be performed at capped black (black shading) and at 50 IRE signal level (white shading).

Vertical Smear

The Vertical Smear measurement evaluates the ability of CCD cameras to handle excessive amounts of light in the input image. Until now, an industry standard to quantify vertical smear had not been established. It was, therefore, difficult to compare cameras from different manufacturers. The VM700T makes that comparison much simpler.

Gamma display.

Shading display.

A black chart with a centered, small aperture is required for this measurement. Vertical Smear monitors three regions of the chart: the aperture (for white reference) and above and below the aperture (for smearing). The camera's iris is first adjusted so the output signal is at the reference white level. It is adjusted again until a predetermined smear threshold is met. The F-stop settings at these points are noted and used to derive the result. The result is expressed in dB, relative to the selected reference white level. The equation used is:

20 log(ref. level/thresh. level) + 20 log(ref. iris/thresh. iris)

Vertical Smear display.

Detail display.

Relative-to-reference

The unique capability of the VM700T to compare measurements against a stored reference is available with the Colorimetry and Frequency Response measurements. This relative-to-reference capability is extremely useful in matching cameras which, in the past, has been a very tedious and subjective process.

Input Formats

Unless otherwise noted, all tests accept GBR, composite and standard color difference component signals in both 525 and 625 line rates.

Ordering Information

VM700T Option 21

VM700T with Camera Measurements Package. Order VM700T Option 21.

VMUPG Option 21

Upgrade kit to add Camera Measurements Package to existing VM700T. Order VMUPG Option 21.