By: John Tucker

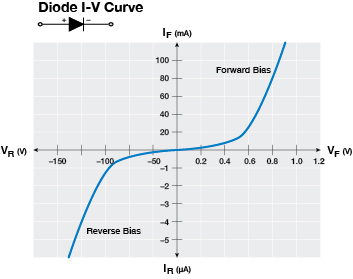

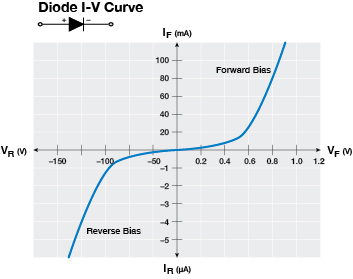

A source measure unit (SMU) instrument is a very precise, wide dynamic range, voltage and current source that also measures voltage and current - all in one tightly-integrated instrument. SMU instruments are mainly used for current-voltage (I-V) characterization of semiconductor components, structures, and materials. Consider the simple electronic diode that conducts current in the forward polarity while blocking current in the reverse polarity. To produce a high quality diode, forward conduction and reverse blocking performance must be precisely characterized, which involves applying current and voltage sources for forward and reverse testing. An SMU instrument can generate and apply constant current and constant voltage of any selected values or polarity to the device under test (DUT.) Many values of current and voltage for both forward and reverse operation can be obtained and graphically represented, as shown in Figure 1.

Figure 1. Forward Vf tests need higher current, lower voltage while reverse Ir tests need higher voltage and lower current covering 6 to 9 decades of dynamic current range and 3 to 4 decades of voltage!

The beauty of using a single SMU instrument compared with a power supply and digital multimeter (DMM) combination lies in the SMU instrument’s capability to typically span nine or more decades of current and four or more decades of voltage. In fact, some SMU instruments can cover an even wider dynamic range, while the best high precision power supplies are generally only capable of less than half the dynamic voltage range and less than a quarter the current range of an SMU instrument.

Simplified wiring to the DUT is another key advantage of using a SMU instrument versus a separate power supply and DMM combination. The SMU instrument connections of voltage source and current measurement for reverse breakdown tests are automatically configured inside the SMU instrument with either two or four wires directly connected to the DUT. For forward measurements, constant current source and voltage measurement circuitry is also configured within the SMU instrument and requires no additional interaction from the user. As a result, a SMU instrument enables the simplest and most flexible forward and reverse testing of signal diodes, LEDs, PV Cells, IC leakage/IDDQ tests, and many other I-V characterization tests.

SMU instruments also provide a complete accuracy specification that includes the various error terms from sources and measurement sections, whereas the combined power supply and DMM approach puts system error determination effort on the user. Modern SMU instruments, such as Keithley’s 2450 and 2460 Interactive SourceMeter® SMU Instruments, have simplified touchscreen user interfaces with built-in standard tests, such as diode I-V curves, transistor hfe or gain, resistance/resistivity, and power, as well as other conventional tests. Plus, these SMU instruments are easily programmable and feature a scripting language that enables infinite tests and automatic customization setups and systems.

Would you like to learn more about the advantages of using a single SMU instrument instead of the DMM/power supply combination? Take a moment to read the article, There’s an Unsung Hero on Your Workbench: The SourceMeter® Source Measure Unit (SMU) Instrument, or contact me at [email protected].