Understanding MOSFET Gate Charge and Its Importance

Power MOSFETs are used in a variety of applications and can be used as high-speed switching. The switching speed of the device is affected by internal capacitances, which is typically specified in data sheets in terms of Ciss and Coss, which are derived from the input gate and drain capacitance, Cgs and Cgd. In addition to specifying the capacitance, the gate charge (Qgs and Qgd) can also be used to assess the switching performance of the MOSFET.

One method of measuring the gate charge of a MOSFET gate charge is described in the JEDEC JESD24-2 standard, "Gate Charge Test Method". In this method, a gate current is forced while the gate to source voltage is measured as a function of time. From the resulting gate voltage waveform, the gate-source charge (Qgs), gate-drain charge (Qgd), and gate charge (Qg) are derived.

The 4200A-SCS Parameter Analyzer supports making MOSFET gate charge measurements using two source measure unit (SMU) instruments and the gate charge measurement test that's included on the system. This test is one of many included in the extensive Test Library provided in the 4200A-SCS Clarius+ Software Suite. This application note describes how to measure MOSFET gate charge based on the JEDEC Gate Charge Test Method using the 4200A-SCS Parameter Analyzer.

How MOSFET Gate Charge Measurement Works

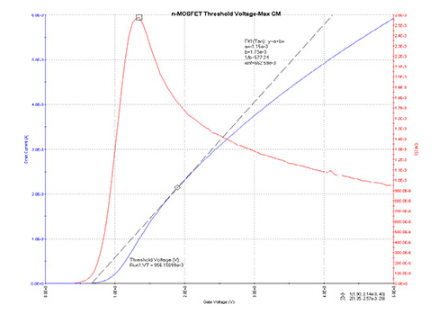

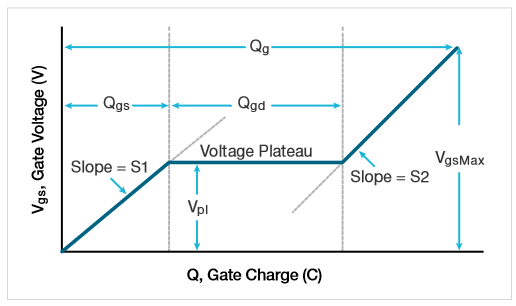

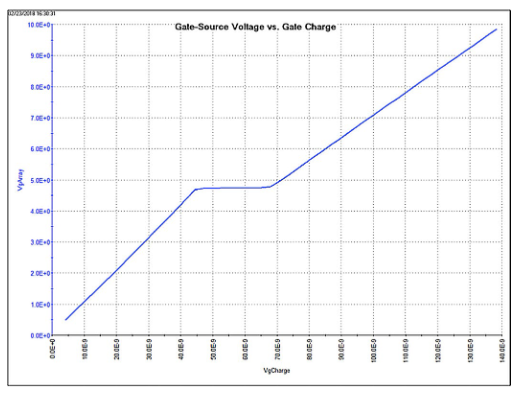

In the Gate Charge Method, a fixed test current (Ig) is forced into the gate of a MOS, transistor and the measured gate source voltage (Vgs) is plotted against the charge flowing into the gate. A fixed voltage bias is applied to the drain terminal. Figure 1 shows the gate voltage vs. gate charge of a power MOSFET.

The gate charge (Q) is derived from the forced gate current and time, (Igdt). The gate-source charge (Qgs) is the charge required, as shown in Figure 1, to reach the beginning of the plateau region where the voltage (Vgs) is almost constant. The plateau (or Miller) voltage (Vpl) is defined, according to the JEDEC standard, as the gate-source voltage when dVgs/dt is at a minimum. The voltage plateau is the region when the transistor is switching from the OFF state to the ON state. The gate charge required to complete this switching—the charge needed to switch the device from the beginning of the plateau region to the end—is defined as gate-drain charge (Qgd) and is known as the Miller charge. The gate charge (Qg) is the charge from the origin to the point where the gatesource voltage (Vgs) is equal to a specified maximum (VgsMax).

S1 is the slope of the line segment from the origin to the first plateau point. S2 is the slope of the line segment from the last plateau point to the specified maximum gate voltage (VgsMax). The slopes are used to calculate Qgs and Qgd, as specified in the JESD24-2 standard.

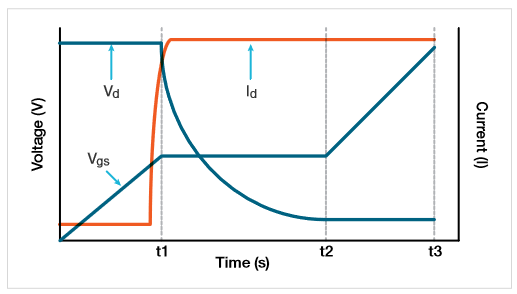

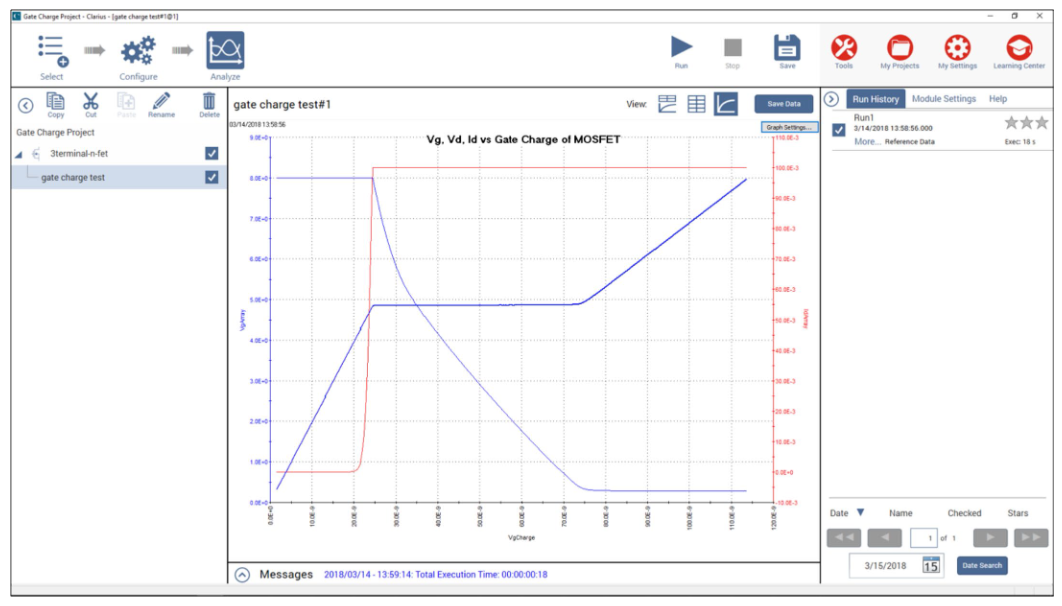

Figure 2 shows typical gate and drain waveforms as a function of time. As current is forced to the gate, Vgs increases until it reaches the threshold voltage. At this point, the drain current (Id) begins to flow. When Cgs is charged up at time t1, Id stays constant and the drain voltage (Vd) decreases. Vgs remains constant until it reaches the end of the plateau. Once Cgd is charged at time t2, the gate-source voltage (Vgs) starts to increase again until it reaches the specified maximum gate voltage (VgsMax).

Using the 4200A-SCS for MOSFET Gate Charge Measurements

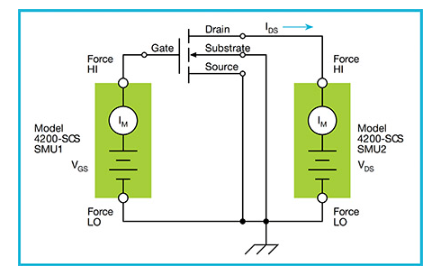

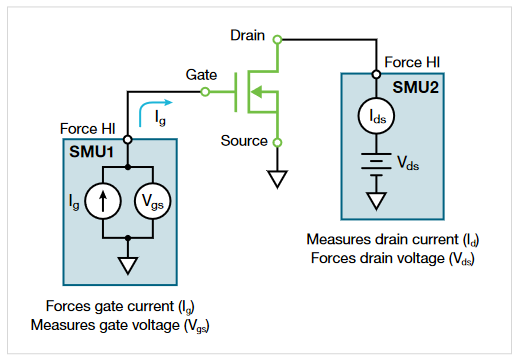

The 4200A-SCS measures gate charge of a power MOSFET using two SMU instruments. Figure 3 illustrates the basic circuit diagram of the gate charge test. The Force HI terminal of one SMU (SMU1) is connected to the gate terminal of the MOSFET and forces the gate current (Ig) and measures the gate-source voltage (Vgs) as a function of time. A second SMU (SMU2) applies a fixed voltage (Vds) to the drain at a specified current compliance (Ib). The maximum compliance current of the 4200-SMU is 0.1 A; the maximum compliance of the 4210-SMU is 1 A.

During the gate charge test, the gate voltage increases and turns ON the transistor. During this transition in the plateau region, the drain SMU (SMU2) switches from voltage control to the current control mode, because the current exceeds the specified compliance level. The software returns the drain current transients and drain voltage during the transition from the OFF state to the ON state.

The MOSFET's source terminal is connected to the Force LO terminal or GNDU of the 4200A-SCS chassis.

Measuring Gate Charge Using Keithley ACS Software

Keithley's Automated Characterization Suite (ACS) Software offers a flexible and powerful environment for electrical device characterization, parametric and reliability test, and simple functional tests. This video demonstrates how to take Gate Charge Measurements using the new Gate Charge ACS Python Test Module (PTM).

Configuring the Clarius+ Software for MOSFET Gate Charge Measurements

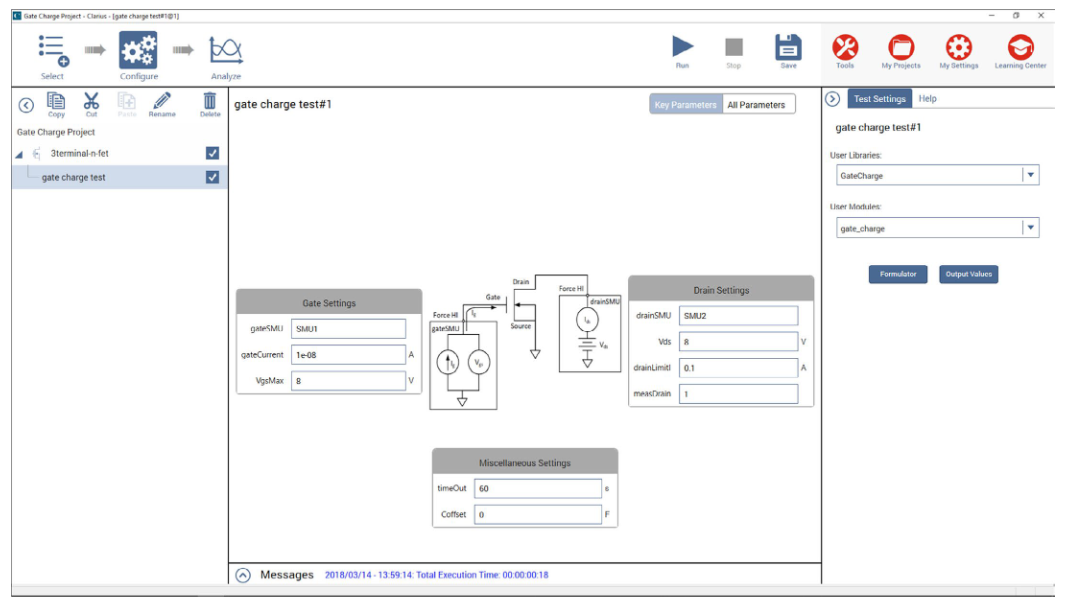

The Gate Charge test is located in both the Test and Project Libraries, which can be found in the Select pane by searching for the phrase "gate charge". Once the test is found in the Test Library, it can be added to a project by selecting and adding it to the project tree. This test was created from the gate_charge user module in the GateCharge user library.

Enter Input Parameters

Before test execution, you need to enter the input test parameters in the Configure pane of the Clarius Software (Figure 4). The input parameters will vary depending on the device and which model of SMU is used.

Descriptions of the input parameters are listed in Table 1. First, enter the SMU numbers that are connected to the gate (gateSMU) and drain (drainSMU) of the MOSFET. The source terminal should always be connected to the GNDU, or Force LO.

The magnitude of the current forced to the gate by the gateSMU, is the gateCurrent (Ig) parameter. The drain voltage (Vds) is the bias voltage applied to the drain and drainLimitI is the compliance current of the drain SMU.

The Coffset parameter is used for correcting for the offset capacitance and is described in the following paragraphs.

Table 1. Input Parameters for gate_charge user module.

| Input Parameter | Range of Values | Default Values | Description |

| gateSMU | SMU1-SMU9 | SMU1 | The SMU number connected to the gate terminal |

| drainSMU | SMU1-SMU9 | SMU2 | The SMU number connected to the drain terminal |

| source | GNDU | GNDU | The source terminal is always connected to the Force LO terminal on GNDU |

| Vds | ± 200 V | 10 V | The magnitude of the drain bias voltage of the drain SMU |

| drainLimitI | 4200-SMU: 0.1A 4210-SMU: 1 A |

0.1 A | Current compliance of the drain SMU |

| gateCurrent | ± 1E-5 A | 1e-7 A | The magnitude of the gate current of the gate SMU |

| VgsMax | ± 200V | 10 V | The maximum voltage level of the gate SMU. |

| timeOut | 0 to 300 s | 60 s | The number of seconds prior to a time out. |

| measDrain | 1 (yes) or 0 (no) | 1 | Return measured drain current |

| Coffset | 0 or Ceff | 0 | Run test with open circuit and then enter Ceff value returned to the Sheet |

Correct for Offset Capacitances

Depending on the cabling and connections of the measurement system, the offset capacitance can be in the single picofarads to hundreds of picofarads ranges. These capacitances can be corrected by executing the gate_charge user module with an open circuit, obtaining the offset capacitance, then entering the offset capacitance value in the software for compensation. Here's how to perform these steps:

- Measure the offset capacitance. Set up the test parameters including the input gate current as though the device were connected to the SMUs. (Increase the VgsMax just for the Ceff measurement.) Prior to executing the test, lift the probes or remove the device from the test fixture. Execute the Gate Charge test with an open circuit.

- Obtain the offset capacitance. After the test is executed, the measured offset capacitance of the system is calculated and appears in the Ceff column in the Sheet. Ceff is derived from the maximum gate voltage, gate current, and time.

Because an open circuit is measured during this step, a Test Status Value of -9 or -12 may appear in the Sheet after the test is executed. This is because no device is measured so there is no plateau region. However, the Ceff value is correct and can be entered as the Coffset in the Configure view. - Enter the measured offset capacitance and execute. Enter the measured offset capacitance, Ceff, for Coffset in the Configure view. By default, Coffset is 0 F. Compensation will be made for the offset capacitance in subsequent readings.

Execute the Test

Once the input parameters have been entered, execute the test by selecting Run at the top of the screen. As the test is running, the gate charge waveform will update in real time in the graph in the Analyze view and the calculated output parameters will appear in the Sheet.

View Output Parameters

After the test is completed, several parameters are returned to the Sheet. Table 2 lists descriptions of these parameters.

Table 2. Output parameters for gate_charge user module

| Output Parameter | Description |

| gate_charge | Test status values - see Table 3 for descriptions |

| timeArray | Measured time (seconds) |

| VgArray | Measured gate-source voltage (volts) |

| VgCharge | Measured gate charge (coulombs) |

| VdArray | Measured drain voltage (volts) |

| IdArray | Measured drain current (amps) |

| Slope | Dynamic slope (dVg/dt) of gate voltage |

| Ceff | Ratio of gate charge to maximum gate voltage |

| Vpl | Plateau or Miller voltage (volts) |

| T1 | Timestamp where the plateau area begins (seconds) |

| T2 | Timestamp where the plateau area ends (seconds) |

| Qgs | Gate charge from the origin to the first inflection point, or the voltage plateau (coulombs) |

| Qgd | Gate charge between the two inflection points in the gate charge curve (coulombs) |

| Qg | Gate charge from the origin to VgsMax (coulombs) |

Graphing the Results

The resulting gate-source voltage can be plotted as a function of the gate charge or the drain current, and drain voltage can be plotted as a function of time. Figure 5 is a typical gate voltage waveform generated by the 4200A-SCS

In addition to plotting Vgs, Vds, and Id can also be plotted as a function of the MOSFET gate charge or time. Figure 6 shows the graph in the Analyze view of the Clarius Software showing all three parameters plotted as a function of the gate charge. In this case, the voltage is shown on the Y1 axis and the current is plotted on the Y2 axis.

Check the Test Status

Each time the test is executed, a Test Status Value is returned to the first column in the Sheet, named "gate_charge". Table 3 lists the returned Test Status Values in the "gate_charge" column and their corresponding descriptions and notes.

Table 3. Test Status Values

| Test Status | Description | Notes |

| 1 | No errors | Test successful. |

| -1 | Gate SMU is not present | Specify correct SMU. |

| -2 | Drain SMU is not present | Specify correct SMU. |

| -3 | VgsMax > 200 V | Verifies gate voltage is less than 200V. Reduce gate voltage. |

| -4 | Drain current limit exceeds 1 A (4210-SMU) Drain current limits exceeds 0.1 A (4200-SMU) |

Verifies drain current is less than 1 A (or 0.1A for medium power SMU). Reduce drain current limit (drainLimitI). |

| -5 | Power limit exceeded | Current should be < 0.1A if V >20V. Decrease drain current limit (drainLimitI) or drain voltage (Vds). |

| -6 | Error check on input conditions. Limits timeOut to 200 s. | Specify timeOut to <200 s. |

| -7 | Test time exceeds specified time out (timeOut). | Increase timeOut. Maximum is 200 s. Try increasing gateCurrent to charge up device faster. |

| -8 | Number of iterations/measurements >10000. | Increase gate current (gateCurrent). |

| -9 | Number of iterations/measurements <5 | Decrease gate current (gateCurrent). Check device, test set-up and for correct SMU. This error can be ignored if it occurs while measuring an open circuit for offset correction. The Ceff value is still valid. |

| -10 | Number of points from origin to first plateau point is <10 | Decrease gate current (gateCurrent) |

| -11 | Error calculating slope, S1. Correlation factor < 0.9. Curve from origin to first plateau point is not linear. | Check device and test set-up. |

| -12 | Error calculating slope, S2. Correlation factor <0.9. Curve from last plateau point to VgsMax is not linear. | Check device and test set-up. If VgCharge or VdArray appear high,try reducing gateCurrent and repeat test. This error can be ignored if it occurs while measuring an open circuit for offset correction. The Ceff value is still valid. |

| -13 | Vds > 200 V | Decrease drain voltage. |

| -14 | gateCurrent > 10 µA | Decrease gate current (Ig). |

Simplifying Your MOSFET Gate Charge Measurement

MOSFET gate charge measurements on transistors can be easily made using the Keithley 4200A-SCS Parameter Analyzer. Using two SMU instruments connected to the gate and drain of the device, the Clarius Software easily derives the gate charge waveforms.

Choosing the right parameter analyzer and SMU configuration for your specific MOSFETs can be complex. Our application experts are ready to help you build the perfect measurement solution.