Compliance testing requirements have long challenged designers and test engineers working with serial standards. The requirements and specifications for these standards are very diverse, and no serial technology stands still for long. In answer to these developments, a powerful class of automated compliance measurement solutions has emerged. Using best-in-class instrumentation controlled in true “systems” fashion by software designed for serial measurement and analysis, these solutions automate the procedures defined in Methods of Implementation (MOI) documents.

Designers are expected, somehow, to keep up with constant change and deliver well-proven, thoroughly compliant and interoperable serial devices. The magnitude of the challenge is daunting. Even as compliance challenges grow more demanding (and more time-consuming), designers must deal with increasing time-to-market pressure. Most designers simply don’t have time to become serial measurement experts, but expertise is what’s needed. Even the fundamental task of interpreting published test requirements may take a broad understanding of measurement tools, serial device behavior, and signal analysis.

Automated compliance measurement solutions are the answer to the compliance challenge. Automation software contains domain-specific knowledge of the applicable MOI, and preset routines to set up and perform tests ranging from Out of Band (OOB) to receiver jitter tolerance to crosstalk measurements and beyond.

Compliance Overview

Compliance testing exists solely for the purpose of ensuring interoperability among serial devices. A PCI Express transmitter on a motherboard must work with the receivers on the attached peripherals. A SATA cable must work with the hard drive connected to it, and so on. Compliance tests are intended to verify this interoperability in advance.

But compliance aims for a moving target. An old adage tells us that "…the only constant is change," a statement that applies absolutely to serial bus technology. To cite an example, one characteristic that is constantly changing is the data rate. Many modern serial data transmission standards have seen their data rates double and double again in recent years.

The original Serial ATA (SATA) protocol came to market with a data rate of 1.5 gigabits per second (Gb/s). SATA Gen II offers 3.0 Gb/s and SATA Gen III more than doubles that, to 8.0 Gb/s. PCI Express and others have followed a similar trajectory.

The effect of this is a diminishing Unit Interval (UI) in which to convey valid, stable data. The SATA unit interval, specified at 666.66 ps in first-generation standards, shrinks to 167.66 ps for SATA Gen III. Jitter and noise levels that were tolerable at the older transmission speeds can cause unacceptably high bit error rates in second and third generation serial systems.

The conclusion here is that compliance testing methods must evolve and adapt just as their target technologies do. And that is exactly what is happening: test requirements are getting more rigorous and more explicitly defined. The serial standards are prescribing more tests, for example those that examine jitter transfer functions or spread-spectrum aberrations. Moreover, because PC architectures are central and common to many standards, a convergence of test methodologies and techniques is all but inevitable. SATA, PCIe, DisplayPort and other test methods will share certain attributes.

It all reflects a growing emphasis on the importance of compliance testing. Designers and manufacturers involved in industry committees specify quantitative requirements for compliance measurements, and sometimes the methods used to achieve these results. The selection of specific tools for the tests is left to those who must perform them, though certain categories of instruments such as real-time oscilloscopes and Bit Error Rate Testers (BERT) may be called out.

Why MOI?

Recognizing that the serial designer’s time is best spent developing innovative ideas rather than studying measurement techniques, compliance testing Methods of Implementation documents have been published for many of today’s leading serial standards. The MOI presents concrete instrument vendor-specific approaches for making the required measurements, including instrument configurations and setups.

Tektronix has led the industry in developing MOI documents that offer detailed, proven solutions for making compliance measurements using its tools. The Tektronix approach is built on interconnected, automated best-in-class instruments interacting as a unified test system.

Compliance Test Requirements and Solutions

Industry working groups such as the SATA-IO and the PCISIG publish clear and timely compliance specifications for the technologies they represent. In turn, MOI documents arise in response to these specifications. A thorough MOI provides a practical solution for every documented compliance requirement. It may also include details about accuracy ranges and limits; additional notes on the measurement procedures; recommended equipment lists; and citations relating the MOI tests to specific sections in the serial standard.

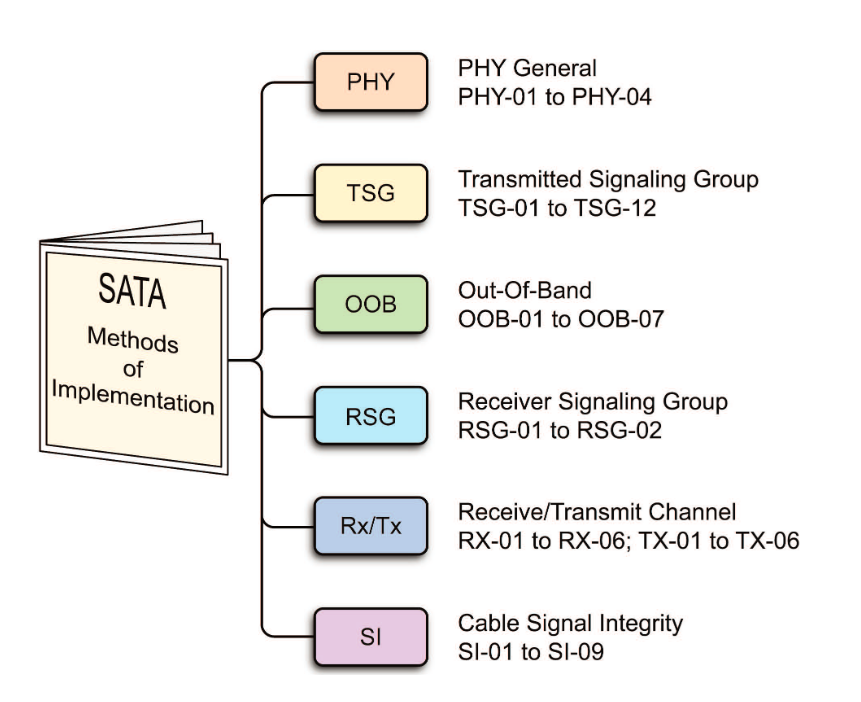

Figure 1 summarizes the tests defined in a typical MOI, in this case one applying to the Serial ATA standard.Many MOI documents can be downloaded from www.tektronix.com/sata.

Forty-six tests comprise the full compliance series for SATA, as shown in Figure 1. Other standards include many of these same categories, though the procedures may differ. The SATA protocol assumes a cable will deliver signals to and from a discrete hard drive, and therefore requires cable tests that may not apply to some other standards.

Following is a general description of each category:

- PHY (Physical Layer) General timing tests are concerned with certain underlying characteristics of the signal timing stability, including Unit Interval as well as Spread-Spectrum Modulation Frequency and Deviation Analysis.

- TSG (Transmitter Signaling Group) tests focus on AC parametrics and jitter—detailed signal characteristics such as Rise/Fall Time, Differential Skew, and both Total Jitter and Deterministic Jitter at two baud rates.

- OOB (Out-Of-Band) tests measure communication signals, particularly the handshakes between the host and an attached device. Tests include Signal Detection Threshold, Unit Interval During OOB Signalling, and various aspects of the COMINT/RESET and COMWAKE communication activity.

- RSG (Receiver Signaling Group) tests measure a receiver’s jitter tolerance.

- Rx/Tx (Receive/Transmit) Channel tests deal with impedances, Return Loss, and other measurements that affect the behaviour of signals from the transmitter and receiver. The active transmitter measurements are taken while the device is operating in its linear region.

- SI (Signal Integrity) tests are performed on cables and connectors, evaluating Channel S-parameters such as Insertion/Return loss, Inter-Symbol Interference (ISI), impedance and crosstalk.

Note that these are strictly compliance tests. Other types of exercises such as RMT (Receiver Margin Tests), though not required in the specification, can also contribute to the overall pursuit of interoperability. And of course comprehensive signal characterization is a requirement for most design projects.

The sheer number of tests in the SATA MOI implies a timeconsuming setup and measurement task. Recognizing this, test instrumentation vendors have developed a variety of solutions to handle the job. These include discrete instruments, self-contained compliance tools, and automated systems.

Discrete Instrumentation

Most industry standards documents do not call out specific test instrument models or brands for compliance testing. In fact, standards committees make every effort to avoid citing vendor-specific products and instrumentation from their published standards documents. This "instrument-agnostic" principle means that the standard defines the end-product (the measurement results), but not the tools used to achieve those results. It is a clean separation that allows the test and measurement industry to create competitive solutions that offer the end-user a wide range of choices. It also gives the standards documents the greatest longevity because they are not bound to the specific product offerings existing at the time the document is written.

Designers and laboratories around the world turn to certain categories of core instruments consistently. These include real-time oscilloscopes, sampling oscilloscopes, BERTs, and signal stimulus systems (both arbitrary waveform generators and digital data generators) as well as generators for the modulating signals that control noise and jitter. Following is a quick survey of these solutions:

Oscilloscopes, being general-purpose tools, are best able to acquire serial signals for in-depth analysis. Consequently they can address most of the measurement applications involved in serial design: characterization, validation, troubleshooting, and compliance. The growing influx of serial protocols in the past decade has allowed for a range of software tools to supplement the hardware features of the oscilloscope platforms. Jitter analysis packages and electrical conformance tools are available to automate key measurement and analysis steps, including DUT state control. The combination of a real-time oscilloscope and its software can carry out all of the measurements in the PHY, TSG, and OOB measurement groups as set forth in the approved SATA-IW Unified Test Definition (UTD).

Sampling oscilloscopes equipped with TDR measurement modules have been allied with software tools to measure characteristics in the Rx/Tx and SI groups in particular, and can handle most of the other test groups as well. TDR features have long been instrumental in serving the impedance and general channel characterization needs of high-speed serial conformance applications. Time Domain Network Analysis (TDNA) approaches using TDR-based stimulus systems have proven their value for analyzing the complex topologies found in many high-speed serial standards.

Bit Error Rate Testers are used to monitor error counts under various test conditions. The Bit Error Rate, or BER, is an essential measure of system behavior but it does little to explain the causes of an error.

The basic BERT concept is simple: it accumulates a record of errors by comparing the DUT output against known-good data over billions of operational cycles. The BERT contains an internal data source that generates the signals fed to its own comparison circuitry as well as the DUT. The internal pattern source offers no conditional or controlled data sequencing, although there may be provisions to add individual jitter terms including sinusoidal, random, and ISI components for receiver testing.

Serial data pulses returning from the DUT are detected when they cross a voltage threshold. The comparison occurs, and the result is logged as an error if the two data streams don’t agree. But when a BERT counts "errors," what does it define as an error? The bandwidth of the BERT’s analog comparator and the intervening channel response leading to the comparator can affect this outcome.

There is an underlying limitation to the bit-by-bit comparison approach of the BERT: it lacks a framing context and therefore has no means of interpreting the relevance of a failed bit, or its placement in the packet. The "error" may be an actual payload data bit, or it might be part of a control word (primitive), or even a token inserted for synchronization. The BERT cannot distinguish frame-related discrepancies from data failures. But significantly, the SATA-IW test standard requires the ability to focus on valid framed contents as part of a receiver compliance test series.

Stimulus systems are required when a BERT is not used (e.g., in oscilloscope-based systems). The stimulus system feeds the DUT with serial data bearing jitter, noise, ISI, and other intentional, controlled flaws. The typical solution here is a data generator (DG). The DG is in turn driven by a waveform generator that can produce sine, triangle, and other formats to modulate the profile of the jitter in the data signal.

The stimulus system is responsible for generating the impaired signals essential to receiver tolerance testing as outlined in the RSG test series. However, there is another important duty known as DUT state control that also requires a “stimulus” signal of sorts. This signal includes a specific sequence of BIST-L frames that puts the serial transceiver into the loopback mode. When the device is in this mode, the transmitter echoes the signal that has been received, and the resulting data can be monitored for errors.

There must be no disconnection or interruption of data in the brief time interval between the BIST-L negotiation and the test stimulus patterns that follow. If such a interruption does occur, most devices will immediately jump back out of loopback mode, making testing impossible. Maintaining the continuity between the BIST-L sequence and the data requires two signal sources. A data generator feeds the pattern data to the DUT. A separate source – usually a computer running a SATA protocol management program – interacts with the DUT through a communications channel shared with a BERT or similar generator via a power combiner structure. Figure 2 illustrates a fully-equipped receiver compliance test configuration with its complexity of power combiners bringing the mix of signal components to the receiver. A setup of this sort is complex to configure and difficult to replicate. Moreover, external elements such as power combiners and even cabling can degrade serial signals in unintended ways.

To date these discrete BERT-based configurations do not offer the integrated tools needed to control the device state and provide the impaired test signals without the use of external switching or signal mixing techniques.

Discrete tools configured properly can handle every imaginable test, but the complexity of the setup may consume more time than today’s design timelines can allow. This complexity also makes it very difficult to replicate a system from one lab to the next. Building up and programming matched systems requires time and costly engineering resources.

Compliance in a Box

A class of integrated, self-contained solutions has emerged to address compliance measurements on specific standards such as PCI Express. The architecture consists of a BERT/sampling oscilloscope pairing supplemented by signal generation and clock recovery features optimized for the standard under test. Everything runs under the supervision of dedicated software tools running on the instrument itself. This software may not encompass every test in the MOI, however.

The self-contained approach provides a convenient way to implement some of the compliance tests that meet particular standards. Like the famous Swiss Army knife, the system combines many tools. But like that same knife, the “blade” is not suitable for surgery and the “screwdriver” is not meant for fixing a jet engine. In other words, the tools do not provide in-depth features for troubleshooting when problems arise, nor do they address standards beyond the single target protocol for which they are configured.

Today’s leading compliance-in-a-box solutions deliver about 70% of the tests outlined in their respective serial compliance standards. Designed for efficient basic compliance testing, some self-contained tools are less comprehensive in their coverage of tests in the RxTx, SI, and OOB series.

The System Approach

Serial designers need a solution that gives them repeatable compliance measurements, quickly and without complex setups or operator intervention. And increasingly they need tools that can also penetrate beyond the basic compliance tests to examine and debug underlying signal attributes.

Best-In-Class Instruments Working as a System

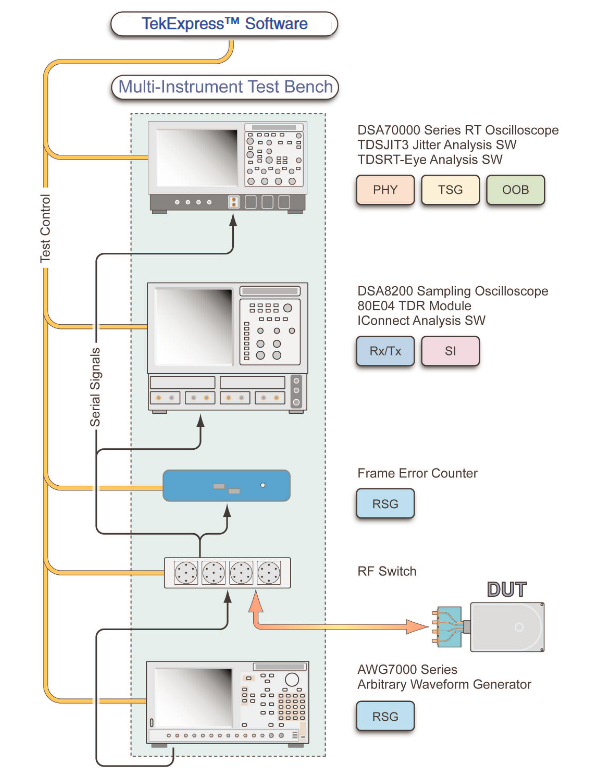

A new toolset is available to address all of the issues related to compliance and design measurements. Enabled by best-inclass instrumentation that is linked controlled by a newlydeveloped software package, this compliance measurement system, known as the Multi-Instrument Test Bench (MITB), provides uncompromised test automation. It can deliver an extended set of features for automated margin testing. Moreover the individual instruments can be applied to any of their usual measurement duties including timing characterization, impedance analysis, troubleshooting, and more. Figure 3 presents a general architectural sketch of the complete automated solution. The test categories adjacent to each instrument are examples of those involving each respective instrument.

The complete system configuration includes:

- A real-time oscilloscope with bandwidth sufficient to capture the 5th harmonic of the serial signal’s fundamental frequency. Residing on this oscilloscope is a family of software tools for jitter analysis, AC parametrics, amplitude measurements, and more.

- A sampling oscilloscope equipped with time-domain reflectometry (TDR) modules that capture data for impedance measurements. The raw impedance information is only the beginning; on-board software tools convert the data into Scattering Parameter measurements which provide return/insertion loss, crosstalk readings and jitter statistics.

- A high-bandwidth arbitrary waveform generator (AWG) that forms serial data signals that contain characteristics including digitally synthesized Inter Symbol Interference (ISI), Sinusoidal Jitter (Sj), Random Jitter (Rj), and spread spectrum clocking (SSC) in pre-determined amounts. The AWG draws on an optional SerialExpress standalone application to speed waveform development.

- A Frame Error Counter that captures frame errors and monitors entities at the protocol level: frames, encoding and protocol errors (including independent CRC verification), and more.

- An RF switch that offers automated programmable signal routing between the DUT and all the test instruments required for any given measurement.

- Software applications that work integrally with the instruments:

- A jitter measurement and analysis application for the real-time oscilloscope

- A serial analysis and TDNA toolset for the sampling oscilloscope

- A waveform development application for the arbitrary waveform generator

- Control panels for the frame error analyzer and the RF switch

- The powerful TekExpress™ multi-instrument control software package automates and manages all of the instruments through the entire MOI test procedure, including measurement sequences, state control, loopback setting, and "handshakes." The software runs on either the integral Windows® XP operating system of the DSA70000 Series oscilloscope or an external host PC running Windows XP.

Because the MITB is built with best-in-class instruments, measurements will embody the highest available accuracy and precision. These same tools can of course be used independently for characterization, troubleshooting, and other measurements unrelated to compliance. Both the hardware components and the TekExpressTM software have the potential to evolve in response to new MOI requirements or even entirely new serial standards.

Faster, Better Compliance Testing

True system-level automation via TekExpressTM and the MITB offers a host of benefits. The most obvious of these is the execution of 100% of the SATA compliance tests specified in the SATA-IW standard. Many solutions automate only portions of the transmitter and receiver test requirements, omitting entire test sequences in some cases. Unfortunately the results establish compliance only with the functions that are actually tested. That leaves the door open for interoperability problems later in the design cycle. True compliance means achieving passing results on 100% of the specified tests – nothing less.

TekExpressTM incorporates the know-how of leading experts in both the serial design and the instrumentation fields. The TekExpressTM software application runs on the National Instruments™ TestStand™ platform, which provides a means to control temperature chambers, power supplies, and similar external equipment as well as the measurement instruments. The control interfaces for the RF switch and the Frame Error Counter are integrated seamlessly into the TekExpressTM software, as are the specialized software tools for analyzing jitter, S-parameters, and more.

After the basic MITB hardware configuration is installed and interconnected, every aspect of that system’s behavior – including the setup steps – is software-controlled. That means the system configuration and presets can be replicated in the lab next door or in a facility in another country with equal ease. In the past it has been very difficult to build duplicate compliance test systems, a task requiring expert installation and programming. Achieving correlation among two or more systems is a challenge as well. Using TekExpressTM software and the multi-instrument test bench, both of these problems are solved. A setup file can be sent via email and used to re-create tests anywhere in the world.

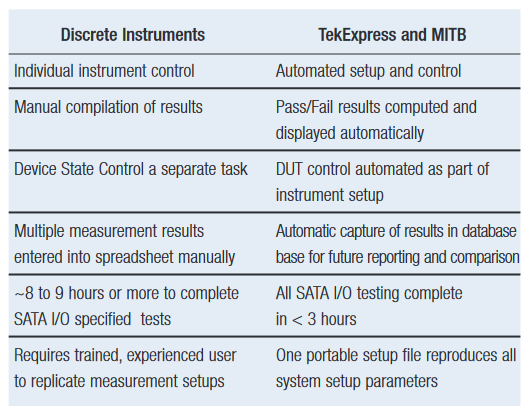

Automation reduces test times by approximately 70% and eliminates inconsistencies in test sequence and test types. There is no chance of overlooking something important due to distraction or time pressure. There is even a schematic of each test setup stored locally, and this can be retrieved to guide you through the process of interconnecting the elements. And reporting, including tabulating of results into standard SATA-I/O formats, is also automated. Table 1 summarizes some of the other advantages of the automated system approach.

TekExpressTM software automatically (or on demand) scans and detects supported instruments connected for the test, whether they are connected through LAN, GPIB, or USB. The Instrument Bench menu confirms all instruments are networked correctly

An Innovation in Serial Signal Production

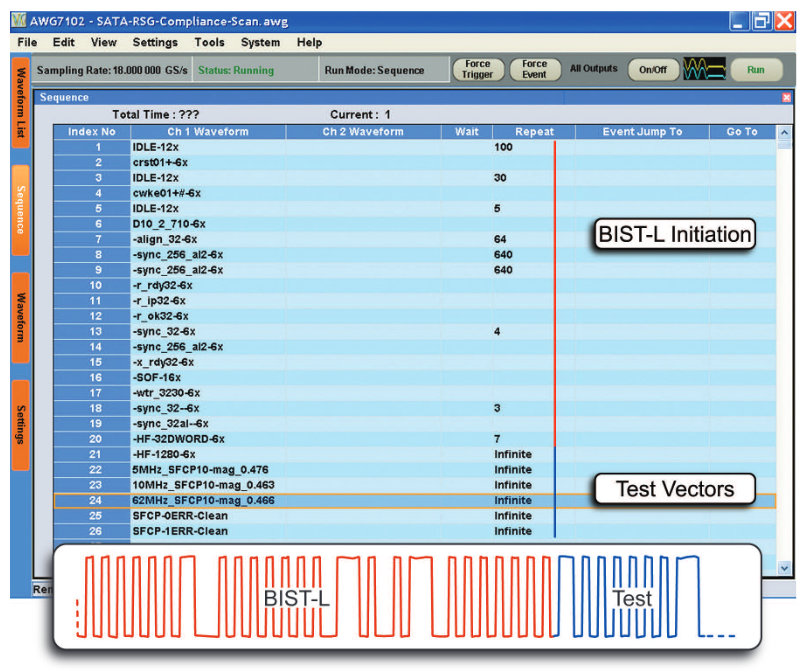

An enabling tool for the whole MITB concept is the high-performance arbitrary waveform generator (AWG), with its ability to deliver signals that can be customized for any serial measurement need. Starting with a simple underlying data pattern, any level of modification can be designed into the waveform. BIST-L codes, for example are contiguous with the test data. There is no need for external modifiers, power combiners, or modulation sources. The waveform itself embodies any or all necessary effects. It is simply a matter of using a waveform development tool such as Tektronix SerialXpress® or a commercial math package to design an appropriate waveform. Figure 4 illustrates a sequence screen from the AWG7102 sequence viewer window showing waveforms created using the SerialXpress package. Thanks to the AWG, it is no longer necessary to reconfigure a complex hardware setup for each type of test and its unique signal requirements. Now the same result can be achieved simply by loading a new waveform file into the AWG.

Tracking Errors at the Protocol Level

The Frame Error Counter used in the MITB addresses a key issue with BERT-based error analysis. A serial message is not just a succession of binary bits proceeding indiscriminately. There are words, double words (DWords), primitives, and even “don’t care” groups used to correct timing differences in embedded clocks. There is a potential for low-level errors like disparity problems; and higher-level framing errors. A conventional BERT cannot distinguish these error types. Even though its fast bit comparison seems like a high-resolution measurement technique, the BERT actually provides less information about the DUT’s behavior.

The Frame Error Counter is rapidly gaining acceptance thanks to its ability to analyze incoming data at the protocol level. A low-level encoding error (such as a prohibited 10-bit value) is detected and identified as such. A DWord containing an invalid primitive is identified as a different kind of error – not just another failed bit. And of course CRC errors shed light on framing and data errors. All of these error types, and more, are reported via the TekExpressTM software.

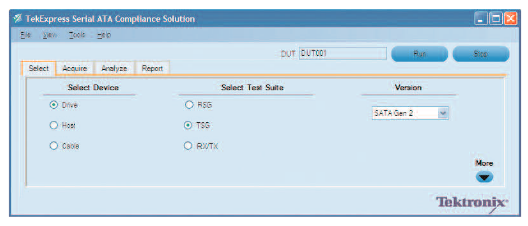

An Overview of the Automated Tests

TekExpressTM software is a configurable product that can be optioned for any and all compliance tests within the SATA Gen I or Gen II specifications. Suitably configured, the hardware/software toolset delivers 100% compliance test coverage for the applicable standard. Each of the following test summaries assumes that the application is equipped with the optional elements necessary to perform the tests in question.

Many of the measurements described herein require TekExpressTM interaction not only with the hardware instruments involved, but also with software analysis packages residing on these instruments – tools such as TDSJIT3 Advanced Jitter Analysis software and 80SICON IConnect® Signal Integrity TDR and S-parameter software. These tools are managed automatically as an integral part of the test program, and results are delivered via the TekExpressTM user interface.

The following test summaries are intentionally simplified, and are not meant to guide the setup or operation of TekExpressTM and the Multi-Instrument Test Bench. The expert application TekExpressTM software knows about calibration steps and setup routines (such as BIST-L procedures and setting up clock recovery parameters) and applies them automatically wherever they are required. The system confirms that the DUT is in a state of readiness before executing a measurement. These are all steps that would otherwise consume the operator’s time and attention.

Using TekExpressTM, the operator need make only a few choices, after which any or all of the compliance test series can be actuated with just one command from the RUN button (Figure 5).

PHY/TSG/OOB Tests

TekExpress, with SATA option, provides 100% automation of the SATA-IO approved PHY/TSG/OOB Method of Implementation (MOI).

For test steps that require putting the device under test (DUT) into the loopback mode, the AWG7000 Series AWG acts as the device state controller. It delivers the BIST-L (Built In Self Test - Loopback) instructions first, and then the mandated data patterns (LFTP, MFTP, LBP, and HFTP) immediately without interruption for the PHY/TSG categories. Moreover, TekExpressTM can also support ‘semi-automated’ PHY/TSG/OOB testing if the DUT signaling does not require an uninterrupted transition from BIST-L code to transmitted data.

The OOB measurements include testing the thresholds and timing of the OOB signals, plus gap length and detection windows of COMINIT/RESET and other communication signals.

Historically PHY/TSG/OOB tests are very time-consuming. SATA transmitter compliance tests alone involve a multitude of measurements. One particular vertical amplitude measurement algorithm is so complex that takes twelve pages of the specification to describe! All this can add up to more than a full day of manually-controlled tests for a single device. With TekExpressTM software and the Multi-instrument Test Bench, the test time shrinks to less than one hour.

RSG Tests and Receiver Margin Tests

Using the real-time oscilloscope, arbitrary waveform generator, and frame error analyzer elements of the MITB, TekExpressTM automates the full RSG test series. The RT scope must be equipped with TDSJIT3 Advance Jitter Analysis software, though the results from TDSJIT3 are ultimately reported via the master TekExpress user interface.

The test begins by initiating a BIST-L sequence that puts the DUT into the loop back mode. After the frame error analyzer confirms that the loop back transmitter is sending valid data, the AWG adds jitter to the data signal at specified frequencies and amplitudes. This handshake between the frame error analyzer and the AWG is of course administered by the TekExpressTM software. In addition, TekExpressTM commands the oscilloscope to calibrate the impaired signal (jitter and amplitude) before the signals are applied during the test.

Once the DUT begins receiving the affected signal, its response determines the outcome of the test. If the frame error analyzer detects errors on the loopback channel, then the device fails the RSG test.

Importantly, TekExpressTM provides additional tools to go beyond the basic RSG compliance tests and into Receiver Margin testing. These capabilities can be used to characterize the receiver’s performance “envelope” and provide valuable information about the device’s extended response to jitter stimuli. The provided signals and jitter profiles can be used, or new ones can be custom-designed using the optional SerialXpress waveform development software running on the AWG7000 Series instrument.

How much jitter tolerance does your compliant device have? Can it survive the rigors of a demanding system application? The RMT series will help you predict its prospects in the real world.

Rx/Tx Channel Tests

Rx/Tx Channel compliance tests examine the dynamic impedance characteristics of operating transmitters and receivers using true differential TDR capability. The sampling oscilloscope, a DSA8200 Digital Serial Analyzer equipped with 80SICON (IConnect® Signal Integrity TDR and S-parameter software, plays the acquisition role in this group of tests. Equally important is the arbitrary waveform generator, which puts the DUT into a specific state prior to the measurements. This state causes the DUT to transmit the standardized MFTP pattern (Medium Frequency Test Pattern), essentially emulating stable, normal operation. An RF Switch performs its usual duty, routing signals among the stimulus and acquisition instruments and the DUT.

The test begins with an automatic calibration performed under TekExpressTM software control. After the AWG forces the DUT into the required mode, a differential TDR module within the DSA8200 sampling mainframe executes TDR measurements and delivers the resulting impedance data to the IConnect analysis tools residing on the sampling scope. The application derives a true impedance profile and S-parameter response from the DUT. As with the other tests involving subordinate analysis applications, the test results are reported by TekExpressTM. These results encompass Rx and Tx true impedance profiles as well as differential, common, and common-to-differential return losses.

Cable Signal Integrity Tests

Though not all standards include requirements for cable signal integrity (SI) testing, Serial ATA does so for an obvious reason: virtually all disk drives are connected to the motherboard via cables. Consequently TekExpressTM software, , with SATA option, provides 100% automation of the SATA-IO approved Cable Signal Integrity measurements (SI) MOI when used with a DSA8200 Digital Serial Analyzer and 80SICON software.

After an automatic calibration under supervision of TekExpress software, data for the SI group of tests proceeds. The DSA8200 excites the differential ports of the cable under test to acquire time domain TDR data. TekExpressTM then passes the measured data to IConnect to compute an accurate impedance profile and frequency domain S-parameters. Time and frequency domain data is then quickly analyzed and the test results are reported via the TekExpressTM user interface.

Pass/Fail Report and SATA Scorecard

The Report tab provides an evolving real-time HTML view of test results along with Pass/Fail status. When testing is complete, TekExpressTM generates a SATA-IO compliant Scorecard in Microsoft® Excel® format (Figure 6). This is the same document that is submitted to SATA-IO for official compliance certification by test houses and at SATA compliance workshops. Like the actual compliance tests, the reports are automatically created – ready for use within moments after finishing the test series.

Conclusion

Interoperability and compliance concerns are commanding an ever-larger share of the serial system designer’s attention. Escalating performance in serial devices means less tolerance for error, and a demand for more rigorous compliance testing. Industry committees, standards bodies, and working groups are answering these demands with exhaustive specifications for device performance and the measurements thereof.

It is a situation tailor-made for fully automated compliance solutions. These can implement consistent test regimes while attending to the details that only compliance experts know. With best-in-class instruments carrying out the measurements, accurate results are assured. Test times can be slashed from days to hours, an asset in these days of shrinking design cycles. And both the hardware and the software components of the automated system can adapt to emerging standards and changing compliance policies.

The fully automated compliance test solution answers the compliance challenges. Now serial designers can get back to their real work: creating innovative, proof-tested serial devices.