Introduction

The electric vehicle market is one of the largest drivers of the increase in demand for rechargeable batteries. These batteries must meet not only tight performance specifications with regard to capacity and lifespan, but also strict safety standards. Electric vehicles necessitate batteries with high energy density, meaning a failure can be catastrophic. These failures can occur at any point in a battery's useful lifespan, including during operation, storage and transport. Since battery demand is increasing globally, transport of batteries is unavoidable.

Transporting batteries can expose them to hazardous conditions that can trigger a failure. Battery manufacturers must take steps to ensure that a battery will not cause harm if damage occurs. These steps include rigorous testing like thermal explosion testing to ensure that a battery will fail safely. Using high quality test equipment like Keithley's DMM6500 digital multimeter, DAQ6510 data acquisition unit and 2260B Series power supply to perform such testing gives manufacturers confidence that their batteries meet all requirements.

Thermal Runaway

Rechargeable lithium-ion batteries are sensitive to changes in temperature. During normal charging and discharging, heat is generated due to internal resistances and the chemical reaction inside the battery. If the temperature of the battery increases enough, the chemical reaction occurs faster. The battery is internally shorted and the increase in current leads to additional heat generation, which creates the cycle of thermal runaway. This continues until the battery is at risk of rupturing, fire or explosion.

Batteries with defects such as higher internal resistance or flaws in their materials and aged batteries are more susceptible to failures. In addition to this, failures such as a fire in one battery can quickly affect nearby batteries. It is critical to prevent a failure such as a rupture or fire from occurring in the first place, so damage is not compounded.

Uncontrolled discharge, or shorting the battery, is oneway thermal runaway can occur. The discharge current can rapidly increase without restriction, generating heat and putting the battery at risk of failure. Transporting batteries puts them at increased risk of unintentional shorting. The short could occur from physical movement or from outside components like shipping containers and contaminants coming in contact with battery terminals. In addition, transportation can expose batteries to heightened temperatures, increasing the risk of thermal runaway.

While it's important to prevent these events from occurring, they do happen, and a battery should be capable of being shorted for a short period of time without catastrophic failure. Standards like "The UN Manual of Tests and Criteria" extensively lay out regulations and criteria for transporting materials that may be hazardous, such as batteries. One test, UN38.3.4.5 tests batteries for behavior regarding an accidental short circuit.

Testing for External Short Transport Safety

The UN38.3.4.5 test for external short circuits requires that batteries are heated to approximately 57 ± 4 °C before beginning the test. The battery is then shorted with less than 100mΩ and the battery is allowed to heat and cool. The short is removed after battery has returned the starting temperature and remained there for at least one hour. For larger battery packs, the temperature can remain below half of the maximum temperature increase observed. A battery passes the test if the overall temperature stays below 170 °C and the battery does not rupture, catch fire or explode during or within six hours of the battery being disconnected after shorting.

Depending on the size and construction of the battery, this test may call for several temperature measurement points. The temperature is to be measured on the external shell of the battery. For a prismatic or pouch cell, transducers such as thermocouples can be placed on each side of the battery to detect any hot spots that may be early indicators of failure. The temperature also must be monitored for over seven hours during the test, so an automated solution that doesn't collect too much data is desirable.

A multichannel solution like a datalogger is ideal for this type of testing. Multiple temperature measurements can be made with a single instrument using a multiplexing scan card. The datalogger can then be programmed to scan and measure each channel in a defined scan interval. An adjustable scan interval allows enough data to be recorded to observe behavior, but not more than is necessary, as measuring over days and weeks can present challenges in data management.

It may also be useful to monitor the battery's voltage during the test. Depending on the requirements for that, this measurement could be a dedicated channel of the datalogger. A separate digital multimeter (DMM) could also be used for continuous monitoring during testing.

The final component needed is a means to heat the battery prior to testing. This could be done using an environmental chamber, though in the event of a failure, damage can occur to the chamber. The shorting test is also intended to be conducted in ambient room temperature, with the battery at the set temperature. Therefore, an external heater can be used to heat the battery, with a DC power supply to power the heater.

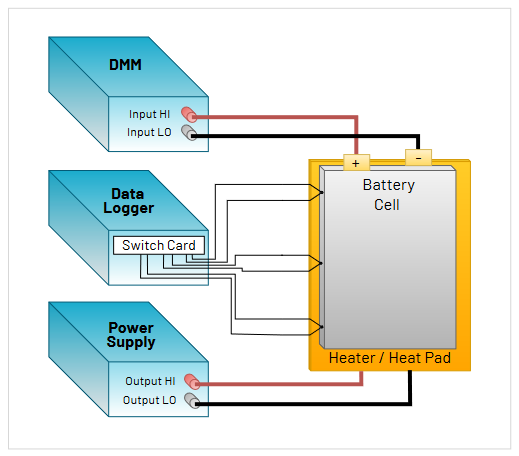

The full test setup is shown in Figure 1.

The Keithley Solution

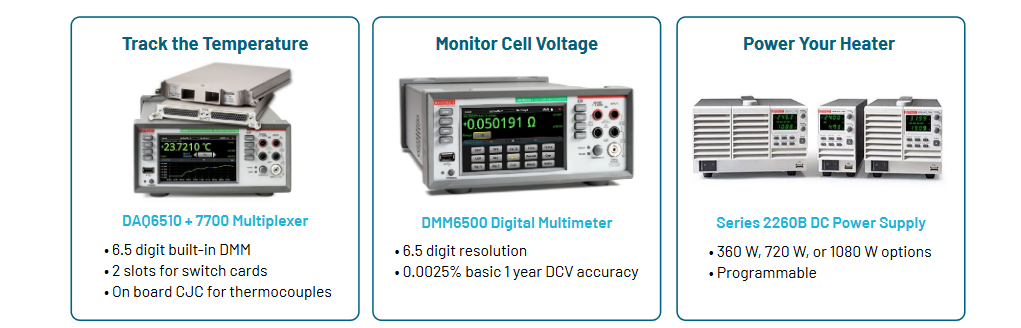

Keithley's portfolio covers the entire external short transport safety test. The DAQ6510 Datalogger is an ideal solution for multiple temperature point testing. The DAQ6510 is capable of monitoring both the temperature and the battery voltage, but for true parallel voltage and temperature monitoring, a separate DMM is required to monitor voltage. The DMM6500 has the same performance as the DAQ6510 for voltage measurements. Finally, the 2260B Series DC power supplies provide a simple solution with a variety of power levels to control the heat source for the battery. Information about each of these products is shown in Figure 2.

Test automation saves time to configure, run and get results from the test. Both the DAQ6510 and DMM6500 are equipped with Test Script Processing (TSP). TSP is a Lua based language that can be executed directly on the instruments, as well as sent from the PC. TSP enables the user to add features such as limits testing. For example, the DAQ6510 can monitor the temperature of the battery while it heats and then switch off the power supply to the heater when the desired temperature is reached, through a communication method called TSP-Net. The DAQ6510 also has pass-fail limits built in, so the instrument can mark data and alert the user when the temperature has exceeded 170 °C.

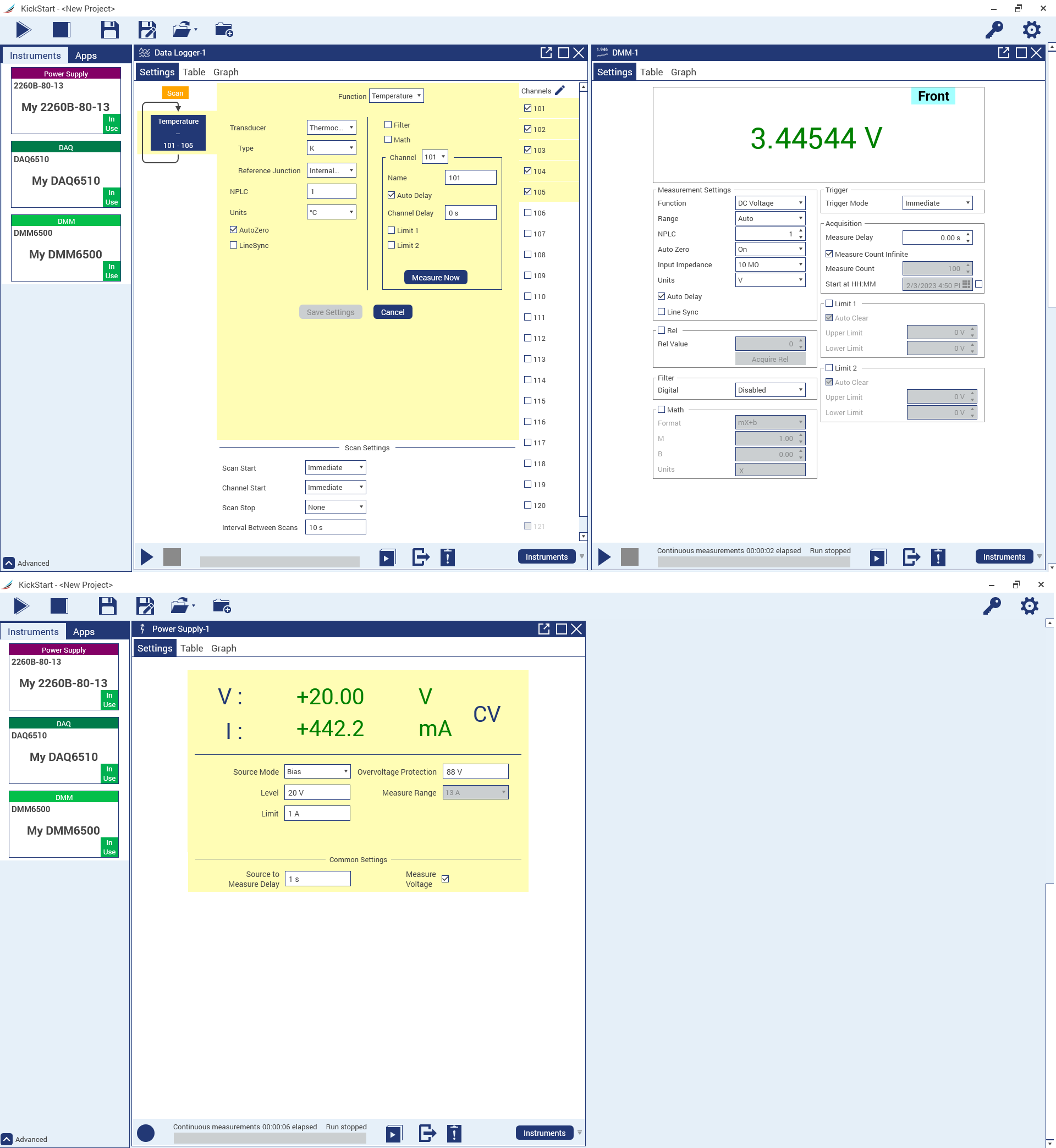

For GUI-based PC automation, Keithley offers Kickstart software. Kickstart makes it simple to configure scans with the Datalogger App, monitor the voltage with the DMM App and control the power supply with the Power Supply App, without the need to write code. Kickstart also has built in table and graph tools to view data collected in real time. The Kickstart configuration view is shown in Figure 3.

Conclusion

Global push to sustainable transportation means we will be shipping increasing numbers of rechargeable batteries. Manufacturers must be able to guarantee that their batteries are compliant with transport regulations like the "The UN Manual of Tests and Criteria" because batteries contain hazardous material and have the potential for extreme failure. Keithley Instruments provides high quality test solutions like the DAQ6510 data logger, DMM6500 digital multimeter and 2260B Series power supply to ensure batteries meet all requirements.

Find more valuable resources at TEK.COM

Copyright © Tektronix. All rights reserved. Tektronix products are covered by U.S. and foreign patents, issued and pending. Information in this publication supersedes that in all previously published material. Specification and price change privileges reserved. TEKTRONIX and TEK are registered trademarks of Tektronix, Inc. All other trade names referenced are the service marks, trademarks or registered trademarks of their respective companies.

02/23 1KW-73991-0