Power Regeneration in Electronic Loads: The Engineer’s Guide to Energy-Efficient Test Systems

As industries accelerate their shift toward decarbonization and energy efficiency, engineers are under growing pressure to reduce waste during testing. Power regeneration in electronic loads offers a smarter, greener way to recover energy instead of dissipating it as heat. This hub blog explains what regenerative loads are, why they matter, and how they connect to broader power testing strategies like bidirectional power supplies and programmable DC sources.

Use this guide as your central resource for learning how regenerative technologies support sustainability, reduce operating costs, and future-proof your test environment.

What Is a Regenerative Electronic Load?

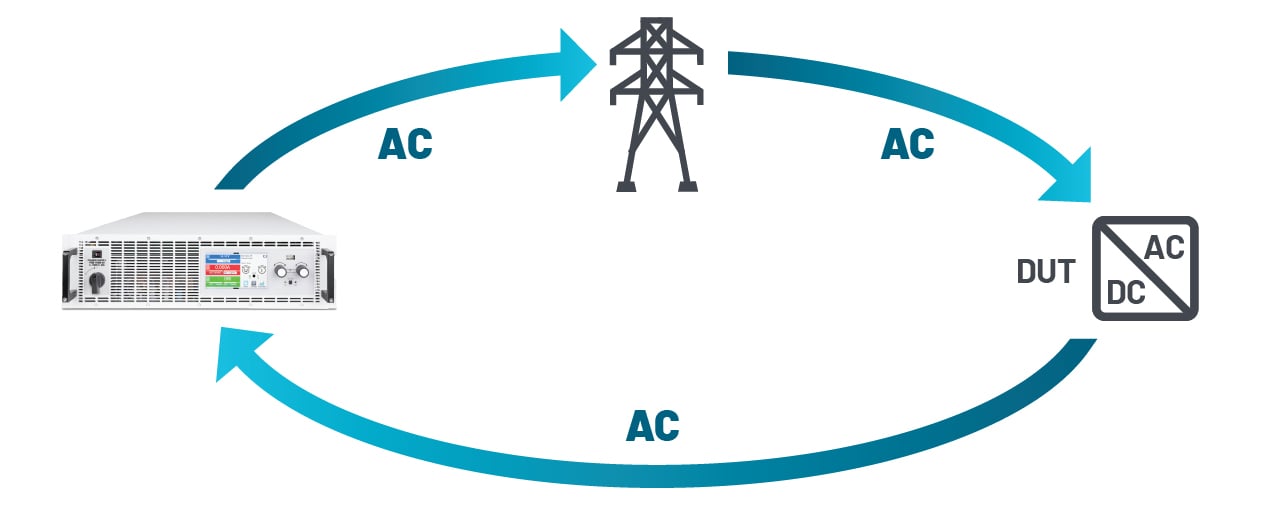

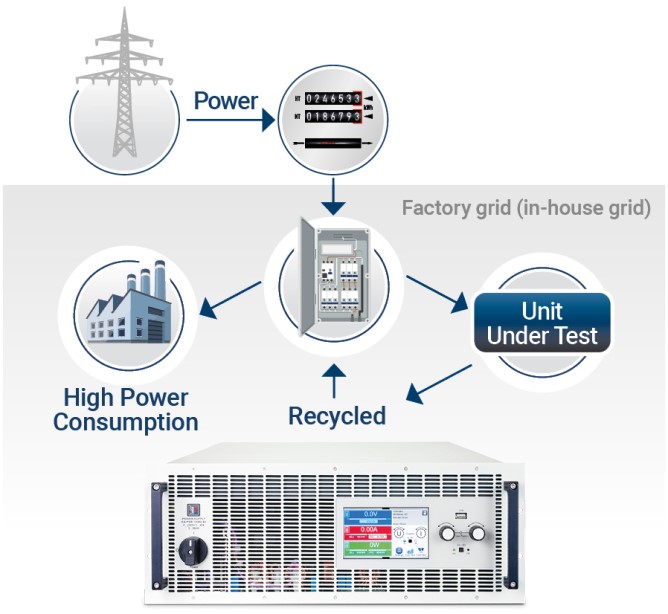

A regenerative electronic load is a test instrument that absorbs energy from a device under test (DUT) and feeds it back to the grid, instead of wasting it as heat. This process improves energy efficiency in lab environments and production lines—especially for high-power applications like battery cycling, fuel cells, and motor drive testing.

Compared to traditional electronic loads, regenerative systems reduce cooling needs, cut power bills, and align with sustainability goals. To explore real-world benefits, read our deep dive on energy savings with regenerative loads.

Why Regenerative Test Systems Are Essential for Modern Engineering

Engineers working in EV development, aerospace, or renewable energy must now balance performance, efficiency, and sustainability. Regenerative loads support that balance with:

- Energy Recovery Efficiency up to 96%: Save energy during every test cycle.

- Reduced Cooling Infrastructure: Lower operating temps mean lower HVAC costs.

- Compliance with Green Initiatives: Align your test systems with corporate ESG goals.

See how this technology supports sustainable aviation in our blog on net-zero emissions in aerospace testing.

Applications of Power Regeneration in Test & Measurement

Regenerative loads are ideal for high-demand test applications where both accuracy and efficiency matter:

Battery Discharge and EV Powertrain Testing

Test EV batteries, chargers, and drivetrain systems while recapturing energy to lower operating costs.

Aerospace Power Simulation

Support electric aircraft and UAV development by simulating load profiles with minimal energy waste. Read more about aviation electrification here.

Fuel Cells and Renewable Energy Systems

Improve testing for solar inverters, fuel cells, and hybrid systems by feeding recovered energy back into the grid.

What Is a Bidirectional Power Supply and How Does It Support Regeneration?

A bidirectional power supply can both source and sink current, making it ideal for regenerative test environments. Unlike traditional unidirectional supplies, bidirectional units simplify test setups and improve flexibility in applications like battery cycling and motor control.

Considering adding one to your test bench? Learn about the advantages in our blog: Should You Consider a Bidirectional Power Supply?

Choosing the Best Programmable DC Power Supply for Regenerative Testing

Your test system is only as strong as your power source. A programmable DC power supply with high resolution, fast response, and regenerative capability will:

- Accurately simulate real-world operating conditions

- Improve automation and repeatability

- Enable integration with bidirectional and regenerative systems

For a comparison of key features, read our expert guide: Choosing the Ideal Programmable DC Power Supply

Products with Regenerative Power Capabilities

We are an industry leader in regenerative power testing solutions offer high-efficiency systems support up to 96% energy recovery and are trusted by engineers across EV, energy, aerospace, and R&D sectors.