Contactez-nous

Chat en direct avec un représentant Tek. Service disponible de 9 h à 17 h, CET jours ouvrables.

Appelez-nous au

Disponible de 9 h à 17 h CET jours ouvrables.

Télécharger

Télécharger des manuels, des fiches techniques, des logiciels, etc. :

Feedback

Student Team Races Ahead with Tektronix Test Equipment

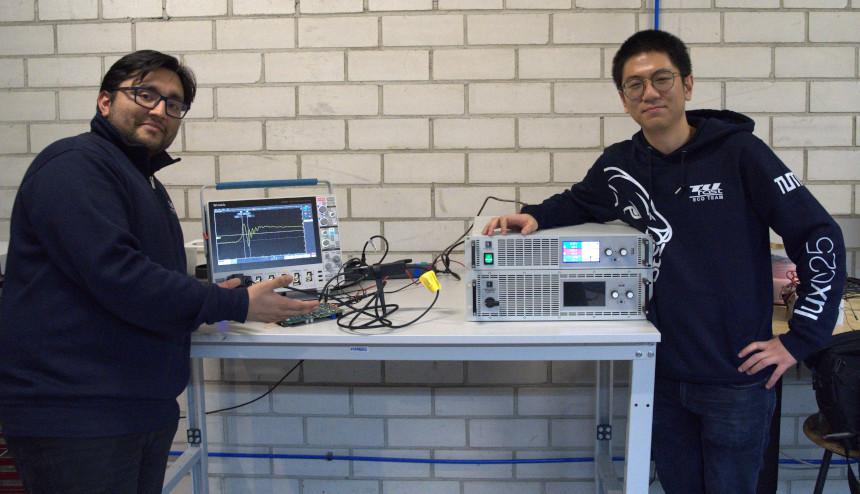

Technical University of Munich Student Team Races Ahead with Tektronix Test Equipment

Student car racing teams have become a much-valued source of education to train for a career in the automotive industry as well as to learn valuable lessons about team building and problem solving. One such team is TUfast Eco from the Technical University of Munich.

Arising from the originally founded TUFast team in 2002, TUFast Eco Team startet their experiences in 2009. Both teams share the same passion of building energy efficient vehicles for the future. TUfast Eco Team has participated in the Shell Eco Marathon for several years and has broken two world records, one in 2016 for the most efficient electric vehicle, and another in 2023 for the longest distance driven by a non-solar electric vehicle - a record it still holds.

However, the TUfast Eco Team students wanted to challenge themselves further by enteringMSO in the biggest solar race in Australia, the Bridgestone World Solar Challenge, in August 2025. The team felt this platform would enable them to showcase their talent and passion for building sustainable vehicles that are designed to go the distance. At this race, the team will drive 3000km through the Australian Outback over a period of five days. In 2023, Tektronix supported Innoptus Solar Team, a racing team from Belgium, in the same challenge which they won. The design of the solar-powered car was tested with a Tektronix oscilloscope, enabling efficiencies and improvements to the car which resulted in a win for the team.

In-house development

Unlike some student racing teams, TUfast Eco Team develops all of its electronics in-house. Its power converters use eGaN-FETs, which help achieve higher efficiency than with SiC mosfets for electrical systems below 200V. It also uses modern topologies such as multilevel converters and paralleling GaN FETs for their lower voltage and current capabilities. This is to showcase how efficient systems using GaN can look in the near future. Such complex designs require adequate time for testing, so after looking at testing equipment from other manufacturers, the team opted for the Tektronix MSO46B oscilloscope to find faults and improve designs for higher efficiencies as well as EA-PSI 10200-70 3U HV power supply from EA Elektro-Automatik to test its high-voltage boards. Previously the team had only developed 48V systems.

“I have always found cars fascinating and it’s exciting to keep pushing ourselves with challenges for our solar-powered vehicle. Since we are taking part in a much more challenging competition than before, we strongly felt the need to move to better in-house testing equipment. We are building a bigger car that will need electronics that can last for days. Driving more than 3000km, or approximately 600 km per day, across Australia is a very tall order,” said Shouryadeep Singh, the team’s head of electrical research., “but we believe we can do it with our knowledge and experience - coupled with professional advice from our partners at Tektronix.”

The team used Tektronix’s MSO46B to test its inverter for analysing the switching characteristics and efficiency. They performed high side measurements, with the TIVP1 isolated probe, which would not have otherwise been possible. Making high-side measurements in half-bridge power converters is challenging because the source or collector to which the measurements are referenced is slewing rapidly up and down. Six channels, however, proved perfect to test the power converters along with the digital probes for the controller boards. In addition, the team was also able to perform comprehensive measurements using TCP0030A current probes and THDP0200 differential probes, which helped find design errors and improve future designs.

The power supply from EA was fundamental to the team’s work because it enabled them to test high-power scenarios to see how the electronics behaved under a broad range of load conditions, which will eventually be the case in Australia. This helped find the peak efficiency of the power converters over a wide range and use that information to develop more effective control systems.

“The previous car we supported had a top speed of around 45km/hr whereas this new car can do 140 to 150km/hr, which represents a big shift in the scale of the project.” said Singh. “However, this time we’re doing our own electronics for our own competitive car. When you try to do these complex electronics by yourself, you need really, really good equipment, which is why we rely on manufacturers like Tektronix.”

EA power supply is the most important thing in the workplace

Another factor was its ease of use. The nature of student-based teams is that they have a rapid turnover of people, so it is vital for new students to be able to get up and running as quickly as possible. According to Singh, who had worked in a previous role with Tektronix and liked the firm’s software some other equipment the team had been trying to use was not intuitive enough,

“Tektronix technology, on the other hand, is very intuitive and easy to use,” Singh said. “I was very much a beginner when I first used it and it made my life so much easier. My aim was to bring that ease-of-use to TUfast Eco Team as there are so many new people excited about joining the team and it not only helps them learn, but to remain as active and constructive contributors.”

The team used three-phase power analysis software along with automotive serial analysis for CAN and decode and trigger for SPI. “We found the user interface very intuitive and all software very well documented,” said Singh. “Since all of the software for the MSO46B is available in the device we have, we can look forward to even more testing and comprehensive learning.”

Singh went on to describe the power supply as “probably the most important thing in our workplace” as it is used to test all the electronics, including the battery power supply unit and inverter. “They have to be capable of 5kW, probably a little more than that,” he said. “This device, that’s up to like 10kW. In the car, we are not going to be doing 5kW but we need to test our electronics for higher power scenarios because in the future I want to improve these designs.”

This is key because all the work Singh and his team are doing is for the first version of the car’s inverter, but they are already planning a second version. “Just improving the efficiency by one per cent can make a massive difference,” said Singh. “With the vehicle, we are attempting to build the perfect application. In other words, we want to build something that is not just better than what the other teams can do, but better than what anyone else in the industry can achieve.”

Tektronix equipment enabled them to do the important tests

Once TUfast Eco Team had the equipment from Tektronix, within one week they were able to do all the important tests, and the Tektronix equipment really accelerated the process.

“Our students work really hard and did not want to spend an additional 40 hours or more in the workshop painstakingly testing something they had built. The MS046B oscilloscope has lots of really cool software that we use for testing our work very quickly” said Singh “And the support we received from Tektronix was phenomenal. Whenever we had a question Tektronix had the answer.” As a student project there are always a lot of hurdles, but the desire to the present our car to the world and see it race in Australia, alongside the support we receive from our sponsors such as Tektronix, brings us enough motivation to tackle any challenges we face.”

All of this contributes to equipping students with the skills to push the boundaries of automotive efficiency. Many team members go on to work in innovative industries, from sustainable mobility solutions to high-performance electric vehicle development. TUfast Eco Team values close collaboration with its sponsors, as these partnerships often lead to exciting career opportunities in the automotive and motorsport sectors.

Not everyone will find themselves in the pit lane of a world championship race, but many of them will help develop the technology that powers the future of mobility—whether in endurance challenges like the Bridgestone World Solar Challenge or in the next generation of electric racing, where efficiency is just as crucial as speed. Shouryadeep Singh and the TUfast Eco Team are proving that with the right equipment—such as the oscilloscope from Tektronix and the power supply from EA Elektro-Automatik—they are learning and applying the skills needed to not only compete in Australia but to shape the future of sustainable performance engineering.