Contactez-nous

Chat en direct avec un représentant Tek. Service disponible de 9 h à 17 h, CET jours ouvrables.

Appelez-nous au

Disponible de 9 h à 17 h CET jours ouvrables.

Télécharger

Télécharger des manuels, des fiches techniques, des logiciels, etc. :

Feedback

Les essais CEM/EMI constituent une étape critique dans les processus de conception et de fabrication des appareils électroniques. Divers organismes de réglementation , dont la FDA, la FCC et l'ISO, ont fixé des limites spécifiques aux émissions qui peuvent être émises par un appareil électronique. Ces réglementations CEM (compatibilité électromagnétique) améliorent la fiabilité et la sécurité de tous ceux qui utilisent des équipements électriques et électroniques, car elles garantissent que l'appareil n'interfère pas avec le fonctionnement d'autres équipements ou qu'il ne fonctionne pas comme prévu en raison d'interférences dues à d'autres émissions. L'échec des tests de conformité CEM sur le site peut entraîner des amendes et des rappels de produits.

L'achat d'instruments capables de détecter les problèmes potentiels de CEM/EMI avant les essais CEM vaut donc la peine d'être investi.Bien que l'IEM et la CEM soient très similaires, il existe quelques différences entre les deux.

Discuter avec un expertQu’est-ce que les interférences électromagnétiques ?

Parfois appelées interférences radiofréquences (RFI), les interférences électromagnétiques (EMI) se produisent lorsque l’énergie électromagnétique perturbe le fonctionnement d’un appareil électronique. La source d’EMI peut être d’origine humaine, comme d’autres appareils électriques tels que les alimentations à découpage, les ordinateurs personnels, ou d’origine naturelle, comme les orages électriques, le rayonnement solaire ou même les bruits cosmiques.

Qu’est-ce que la CEM ?

La compatibilité électromagnétique (CEM) est la capacité d’un appareil à fonctionner comme prévu dans un environnement avec d’autres appareils électriques ou sources d’interférences électromagnétiques sans affecter ces autres appareils. Un appareil est dit conforme à la CEM lorsqu’il n’influence pas l’environnement électromagnétique au point d’affecter négativement d’autres appareils et systèmes.

Qu’est-ce que les tests EMI et CEM ?

Pour garantir la conformité aux réglementations nationales et internationales EMI et CEM, de nombreuses entreprises font appel aux services d’un centre d’essai spécialisé. Comme ces tests sont coûteux, même si le produit échoue, plusieurs entreprises effectuent des tests de pré-conformité CEM en interne. Si elles disposent d’un laboratoire suffisamment sophistiqué, les entreprises peuvent également effectuer des tests de conformité CEM en interne.

Les essais CEM/EMI sont généralement divisés en deux catégories : les essais d'immunité et les essais d'émission.

Types d'essais CEM

Lorsque l’électronique est soumise à des laboratoires de test CEM, il existe de nombreux types de tests CEM exécutés par ces laboratoires. D’une manière générale, les tests CEM sont divisés en deux catégories : les tests d’immunité et les tests d’émissions.

Test d’immunité

Les tests d’immunité sont le processus de transmission d’énergie RF sur un dispositif testé (ASE) (également appelé équipement testé ou EUT) pour déterminer si ASE/EUT fonctionne correctement dans un tel environnement.

Essais d’émissions

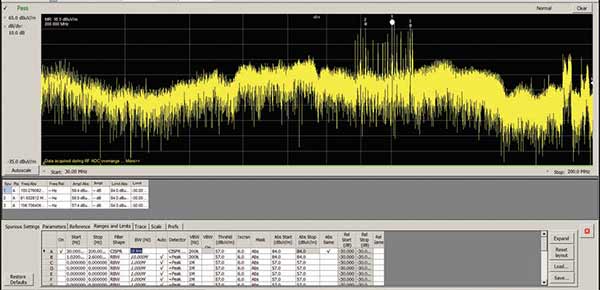

Les essais d’émissions sont le processus qui consiste à mesurer les émissions RF – rayonnées et effectuées – d’un ASE/MAE afin de déterminer si ses niveaux d’émissions ne dépassent pas les limites définies par la norme appropriée. Les essais d’émissions comprennent des essais d’émissions rayonnées et des essais d’émissions effectués.

Émissions rayonnées

Émissions rayonnées sont les émissions intentionnelles et non intentionnelles d'énergie électromagnétique provenant d'un appareil électronique. Un essai de rayonnement est effectué pour s’assurer que les émissions émanant de l’ASE ou du MAE sont conformes aux limites applicables.

Émissions conduites

Les émissions conduites sont le couplage de l'énergie électromagnétique d'un appareil avec son cordon d'alimentation . Comme les émissions rayonnées, les émissions conduites autorisées des appareils électroniques sont contrôlées par différents organismes de réglementation et des tests sont effectués pour s’assurer que les niveaux d’émission sont inférieurs aux limites applicables.

Applications et normes d'essais EMI/EMC

Les tests EMI/EMC font partie du processus de développement des produits et sont obligatoires sur la plupart des marchés. Bien que tous les appareils électroniques ( ) soient soumis à des essais CEM, voici quelques-unes des applications les plus courantes des essais CEM et des normes auxquelles les appareils et les équipements doivent satisfaire.

| SEGMENTS DE MARCHÉ | Type d'équipement | NORMES | ||||

|---|---|---|---|---|---|---|

| CEI/CISPR | CENELEC/EN | FCC | MIL-STD | DEF-STAN | ||

| ISM MEDICAL | Appareils industriels, scientifiques et médicaux | CISPR 11 | EN 55011 | CFR Titre 47 Partie 18 | ||

| Appareils électriques médicaux | NF EN 60601-1-2 | |||||

| AUTOMOBILE | Véhicules, bateaux et moteurs à combustion interne | CISPR 12 | EN 55012 | CFR Titre 47 Partie 15(*) | ||

| Composants et modules embarqués pour véhicules | CISPR 25 | NF EN 55025 | ||||

| MULTIMÉDIA | Récepteurs diffusion TV et audio | CISPR 13 | EN 55025 | CFR Titre 47 Partie 15 | ||

| Équipements ITE (technologies de l’information et télécommunications) | CISPR 22 (remplacée par NF EN 55032) | NF EN 55022 (remplacée par NF EN 55032) | ||||

| Équipements audio/vidéo/multimédia professionnels | CISPR 32 (remplace les normes CISPR 13 et 22) | EN 55032 | ||||

| APPAREILS | Appareils électriques, domestiques et outils | CISPR 14-1 | NF EN 55014-1 | CFR Titre 47 Partie 15 | ||

| LUMINAIRES | Lampes fluorescentes et luminaires | CISPR 15 | EN 55015 | CFR Titre 47 Partie 15 | ||

| DÉFENSE | Équipements et systèmes militaires | MIL-STD-461G | DEF-STAN 59-411 | |||

Éliminer toute part d’incertitude dans les tests EMI/CEM

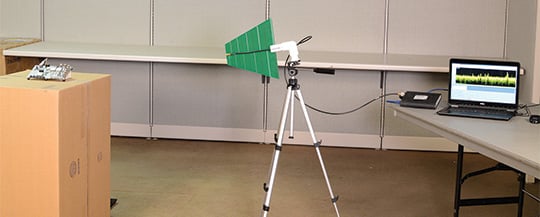

Utilisez une configuration de test par radiation standard avec un Analyseur de Spectre USB Tektronix RSA500.

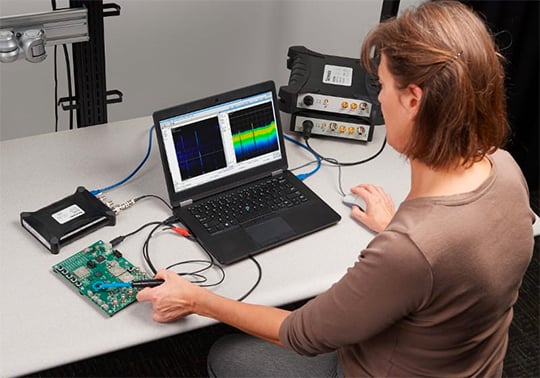

Le test de pré-conformité EMI/CEM n’est pas nécessairement difficile ou long à réaliser. Sur la base de ses retours client, Tektronix a mis au point une nouvelle solution logicielle qui se veut fonctionnelle et facile à utiliser pour proposer des tests de pré-conformité pour les mesures d’émissions par radiation et par conduction.

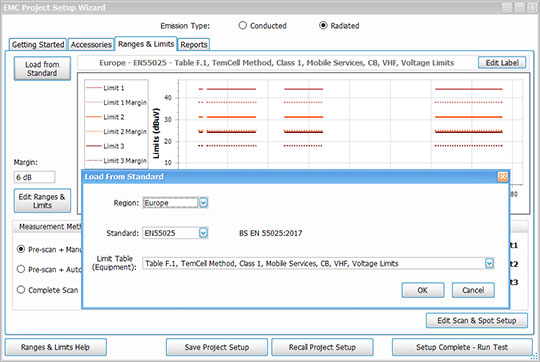

La configuration des tests de pré-conformité EMI/CEM commence avec SignalVu-PC. Cette dernière version de SignalVu-PC est désormais fournie avec une option supplémentaire qui s’appelle EMCVu. La solution EMCVu est dotée d’un assistant de configuration simple d’utilisation, de normes intégrées et d’accessoires avec sélection des fonctions par bouton-poussoir. Que vous installiez un site d’essai en plein air (OATS, Open-Air Test Site) ou que vous effectuiez les tests dans votre laboratoire, le logiciel EMCVu rationalise la capture et l’élimination du bruit ambiant dans vos mesures, afin d’améliorer la précision de vos tests de pré-conformité sans recourir à une chambre anéchoïque.

Pour en savoir plus sur l’utilisation d’EMCVu avec les accessoires et analyseurs de spectre en temps réel, téléchargez la note d’application ici.

Si vous êtes intéressé par un essai gratuit d’EMCVu pendant 30 jours, cliquez sur le bouton ci-dessous.

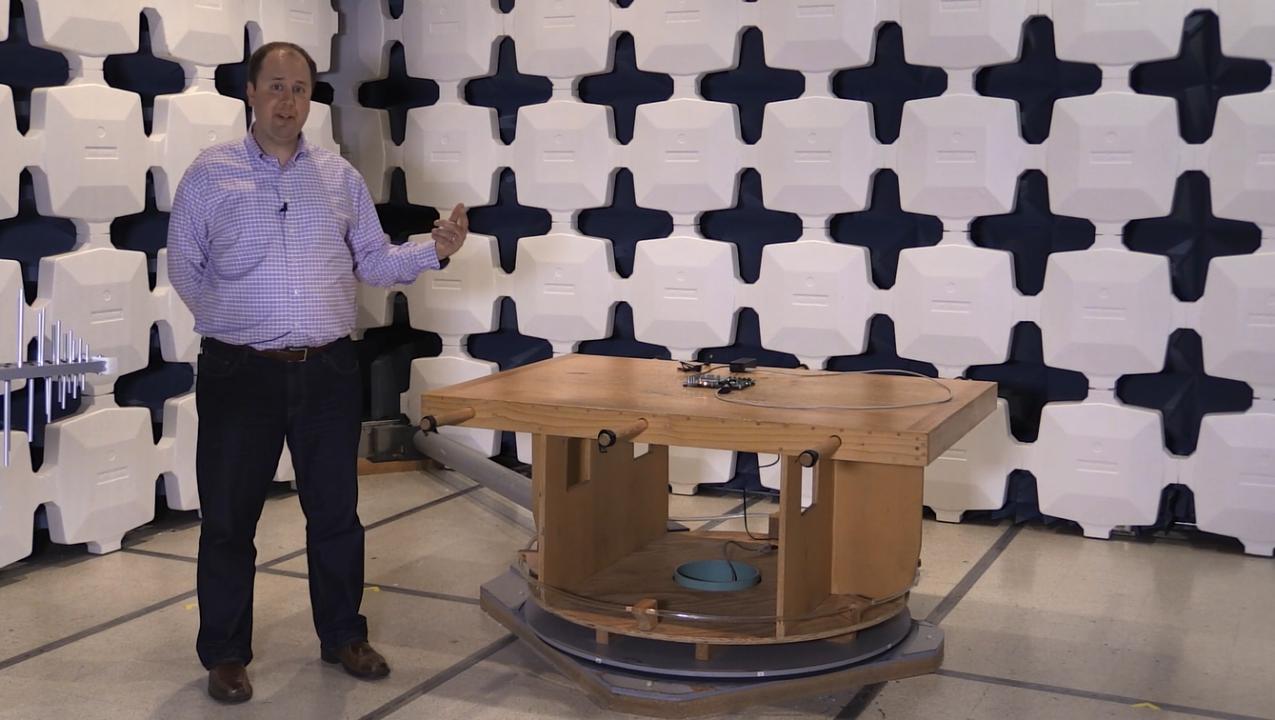

Laboratoires d'essais CEM

Les tests de conformité CEM sont généralement effectués hors site avant la production d’un appareil. Les sites d’essais en plein air, ou OATS, sont les sites de référence utilisés pour la plupart des normes. Ils sont particulièrement utiles pour les tests d’émissions des systèmes de gros équipements. Cependant, les tests RF d’un prototype physique sont plus souvent effectués à l’intérieur, dans une chambre anéchoïque spécialisée. Les types de chambres comprennent l’anéchoïque, la réverbération et la cellule électromagnétique transversale gigahertz (cellule GTEM).

Procédure d'essai CEM et taux de réussite moyen

Environ 50 % des produits réussissent leur premier test de conformité EMC lorsque la pré-conformité n’est pas prise en compte, il est donc essentiel de comprendre le processus et les normes selon lesquels un périphérique est testé afin d’augmenter vos chances de succès.

-

Connaître ses normes

Il existe une variété de normes CEM qui spécifient des procédures de test et des limites pour les émissions par rayonnement et par conduction. Ceux-ci varient selon le pays et le type d’équipement testé. La première étape des tests consiste à déterminer quelles normes s’appliquent à votre produit et à rechercher les procédures de test et les limites requises pour la conformité.

-

Effectuer des essais CEM de pré-conformité

Les tests de conformité CEM peuvent prendre jusqu'à deux semaines - sans compter le temps nécessaire pour mettre votre produit dans la file d'attente des tests - et peuvent coûter jusqu'à 20 000 dollars par soumission. Un défaut de conformité CEM peut entraîner des refontes coûteuses et des retards de lancement de produits. Et comme près de 50 % des produits échouent à leur premier test de conformité CEM lorsque la pré-conformité n’est pas prise en compte, il est probable que vous deviez répéter votre visite à la maison de test, ce qui multiplie les coûts au fil du temps.

-

Trouver un laboratoire d'essais CEM

Une fois qu'un produit a été soumis à des essais de pré-conformité et qu'il les a réussis avec une marge suffisante, il doit être officiellement certifié par un laboratoire d'essais CEM. Les laboratoires accrédités sont la référence en matière de tests CEM et le choix d’un laboratoire accrédité est toujours recommandé, mais pas nécessaire, pour s’assurer que votre appareil est prêt à être mis sur le marché. Il existe toutefois certains cas qui nécessitent une certification d’un Laboratoire accrédité FAC, y compris les appareils qui relèvent des procédures d’autorisation de « certification ».

Comment réussir les tests de compatibilité CEM ?

Les tests de préconformité CEM sont un moyen rapide et abordable de s’assurer que les produits réussissent les tests CEM dès la première fois. Ultérieurement au cours du cycle de développement, les tests de pré-conformité sont utilisés pour détecter les problèmes de conformité et améliorer la probabilité de réussite du premier test de conformité CEM.

Les tests CEM de pré-conformité présentent d’autres avantages :

- Détection des erreurs à un stade précoce, corrigeant les problèmes potentiels ;

- Réduction des coûts de test et de conception ;

- Les projets deviennent plus agiles ;

- Réduction du risque de défaillance et assure la conformité ;

- Résolution à la fois de la sur-conception et la sous-conception et l’ingénierie.

Pour mieux comprendre comment une installation de test de pré-conformité Tektronix se compare à un laboratoire de test CEM, regardez cette courte vidéo.

Mise en place d'un laboratoire d'essais CEM de pré-conformité

Lors de la sélection d’un site d’essai, les zones rurales, les salles de conférence et les sous-sols sont de bonnes options car ils minimisent les signaux externes qui pourraient masquer les niveaux d’émission de l’ASE que vous essayez de mesurer. D’autres considérations pour améliorer la précision incluent un bon plan de masse et la réduction du nombre d’objets réfléchissants autour de la zone de test.

Produits d'essais EMI et EMC

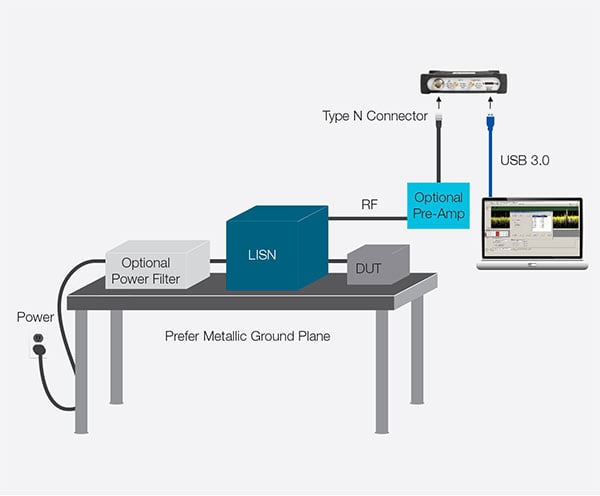

L’objectif des tests de pré-conformité CEM est d’imiter le test de conformité mis en place dans une marge acceptable pour découvrir les problèmes potentiels et réduire le risque d’échec avant le test de conformité coûteux. Les tests de préconformité CEM impliquent généralement :

- Analyseur de spectre avec détecteur de quasi-crête

- Préamplificateur (en option)

- Antenne avec support non métallique pour les émissions rayonnées

- Réseau de stabilisation d’impédance de ligne (LISN) pour le test effectué

- Limiteur de puissance pour l’essai effectué

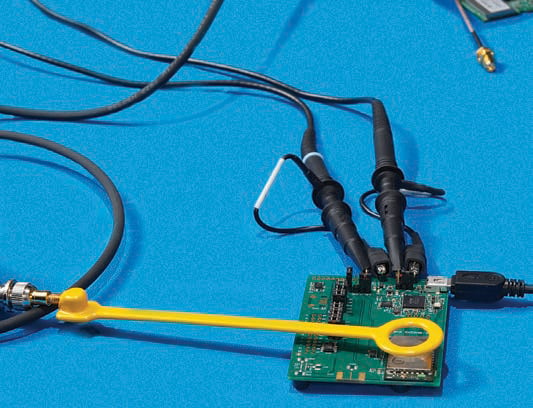

- Sondes en champ proche CEM pour le diagnostic (en option)

- Oscilloscope avec capacités de corrélation de fréquence et de temps pour aider au débogage (en option)

- Logiciel de test CEM

Centre de ressources pour les essais CEM

APPLICATION

Solutions d'essais de pré-conformité CEM/EMI

Découvrez les solutions de pré-conformité CEM/EMI de Tektronix et la manière d'assembler une configuration de test de pré-conformité, et obtenez des conseils de dépannage.

Blog

Avantages financiers des essais de pré-conformité EMI/EMC

Obtenez une estimation des coûts des essais CEM et des économies que vous pouvez réaliser en mettant en place une solution interne d'essais de pré-conformité.

Étude de cas

Analyse 3D rapide de la CEM/EMI avec le système de balayage Detectus et les analyseurs de spectre en temps réel Tektronix

Téléchargez cette étude de cas client pour découvrir comment la start-up à croissance rapide Eggtronic a utilisé un analyseur de spectre en temps réel Tektronix pour mettre en place une procédure de balayage extrêmement rapide afin de s'assurer que ses produits respectent les normes CEM/EMI.

Note d’application

Dépannage des problèmes CEM/EMI avec Tektronix EMCVu

Téléchargez cette note d'application pour savoir comment remédier aux défaillances de conception les plus courantes à un stade précoce, lorsque les coûts d'une nouvelle conception sont minimes.

Trouvez dès aujourd'hui la solution d'essais CEM de pré-conformité adaptée à votre activité.

Discuter avec un expert