Kontaktaufnahme

Live-Chat mit Tektronix-Vertretern. Verfügbar von 9 bis 17 Uhr CET Geschäftstage.

Kontaktieren Sie uns telefonisch unter

Verfügbar von 9 bis 17 Uhr CET Geschäftstage.

Download

Laden Sie Handbücher, Datenblätter, Software und vieles mehr herunter:

Feedback

Einfach kompetent erledigt

Tektronix dient als Erweiterung Ihres Teams und bietet maßgeschneiderte Lösungen für Kalibrierdienste, die Zeit und Kosten sparen und die Genauigkeit von elektronischen Test- und Messgeräten gewährleisten. Wir arbeiten mit Ihnen zusammen, um die intelligentesten Geschäftsentscheidungen bei der Erweiterung oder Auslagerung von Kalibrierungen anspruchsvoller Prüf- und Messgeräte zu treffen. Täglich verlassen sich Tausende von Unternehmen bei der Bereitstellung von OEM-Qualitätskalibrierungen zu einem wettbewerbsfähigen Marktpreis auf Tektronix.

- Wartung von Tektronix, Keithley, Fluke, Keysight, Rohde & Schwarz, Agilent und mehr als 9.000 weiteren Prüf- und Messgerätemarken

- Maßgeschneiderte Programmoptionen: Vor-Ort-Service, Abholung, Lieferung bis Werk

- Schnelle, zuverlässige Bearbeitungszeiten

- Vollständige Palette nach Z540 und ISO 17025 akkreditierter Kalibrierungen

- A2LA-zertifizierte technische Fachkräfte

Semiconductor Assembly and Test Services

Überall, wo Sie uns brauchen

Tektronix bietet das weltweit umfassendste Netzwerk von Kalibrierdienst-Laboren für Prüf- und Messgeräte. Mehr als 1.100 erfahrene und zertifizierte Techniker warten Ihre Geräte in ca. 100 Laboren weltweit. Für globale Unternehmen sind wir Ihr lokaler Partner für die Verwaltung der Kalibrierungsprogramme für Ihre gesamte Geräteflotte an mehreren Standorten.

Standorte der Servicecenter

"Tektronix' upfront communication on issues was key to solving problems in a timely manner and keeping our development on schedule. Quick responses to requests from programs, engineering, and supply chain regarding schedule were crucial in keeping projects on track."

-Defense Contractor Supply Chain Manager

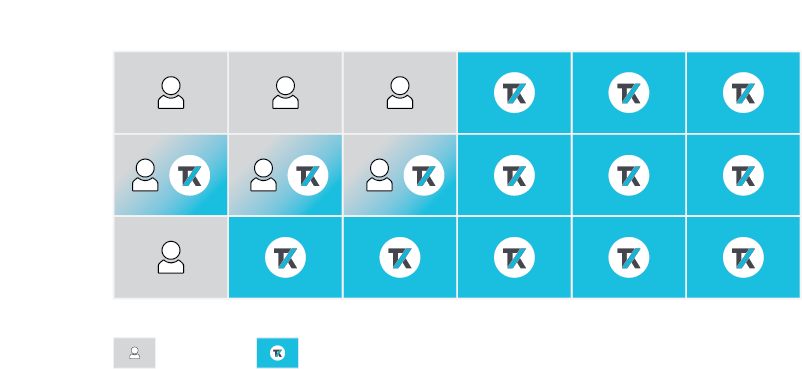

Tektronix Component Solutions offers a wide range of collaboration business models. From simple outsourced assembly and test, to complete turnkey services, we have the flexibility to integrate with your business in the manner most effective for you. We help our customers succeed across a wide range of activities from early design and simulations, through advanced packaging prototyping, and on to full volume production.

Tektronix Component Solutions is a U.S. Dept. of Defense, Defense Microelectronics Activity Category 1A Trusted Supplier to deliver trusted foundry goods and services.

Problem Solving Is Our Way of Life

Tektronix Component Solutions is an operating company of Fortive. Problem solving and continuous improvement is at the heart of everything we do. The core of our continuous improvement is the Fortive Business System – our proven system for progress.How we accelerate impact.

The Fortive Business System (FBS) is a powerful set of tools and methods that help us drive growth and innovation, ensure safety and quality, minimize waste, deliver for our customers, lead effectively, and scale our successes. It’s fundamental to who we are and how we work, and we continuously adapt and evolve it to propel us forward across disciplines, industries, and geographies.A strong foundation with unlimited possibilities.

FBS was born in the mid-1980s, when one of the Fortive companies studied Japanese lean manufacturing principles in response to intensifying competition. The new practices were so transformative that they were applied across Fortive companies, beyond the factory floor. Over time, we have developed processes and added tools to support all of our businesses and functions, from construction management and medical device calibration to software development.

Today, FBS is far more than a productivity initiative—it’s our competitive advantage for driving innovation and delivering transformational technology for our customers, and it’s always evolving along with our businesses. We apply FBS to drive continuous improvement and accountability in everything we do, from inclusion & diversity and leadership to workplace safety, sustainability, and innovation.