Why Invest in EMC Pre-Compliance Test Equipment?

Full compliance EMC testing (or EMI testing) can be exhaustive, time consuming and expensive. Many compliance tests don’t pass the first time, so without any due-diligence, it’s likely you’ll need to repeat your visit to the test house, multiplying costs over time.

An affordable and convenient alternative to using fully accredited EMC compliance labs is investing in an in-house pre-compliance EMC test solution. Pre-compliance EMC testing does not require a semi-anechoic chamber (SAC) or EMC chamber, and the equipment is less expensive than full compliance test equipment. This is because the goal of pre-compliance EMC testing is to mimic the compliance test setup within an acceptable margin to uncover potential problems and reduce risk. Having your own pre-compliance test solution increases the likelihood of catching compliance problems early in the design phase and improves the probability of a successful first pass with the full compliance test.

This blog post will describe the seven items required in a pre-compliance radiated emissions EMC test, because the most common EMC failure encountered by designers during a full EMC compliance test is due to radiated emissions.

7 Essential EMC Pre-Compliance Instruments and Accessories

- Real-time spectrum analyzer

- Antenna(s)

- Preamplifier

- Antenna tripod

- Cables

- Low-noise test environment

- Turn table

--------------------------------------------------------------------------

1. Real-time spectrum analyzer

Unlike a traditional spectrum analyzer, a real-time spectrum analyzer has the ability to capture intermittent or infrequent signals with high precision and high probability of intercept. But what frequency range is required for EMC testing?

The frequency range required will depend on the standard and region you will be testing for. The lowest frequency range is typically determined by the lowest frequency clock included in your design. The maximum frequency measurement range will be a factor of the highest frequency generated or used in the device or on which the device operates or tunes. Here’s how the FCC defines it for unintentional radiators (including a digital device):

| Highest frequency which is generated or used in the device, or on which the device operates or tunes | Upper frequency of measurement range |

| Below 1.705 MHz | 30 MHz |

| 1.705 -108 MHz | 1000 MHz |

| 108 - 500 MHz | 2000 MHz |

| 500 - 1000 MHz | 5000 MHz |

| Above 1000 MHz | 5th harmonic of the highest frequency or 40 GHz, whichever is greater |

There are many caveats with this depending on the type of product. For understanding this more for your exact frequency measurement range, I suggest reading FCC Part 15.33 or buying your specific standard and seeing what it says.

Important things to look for when deciding on a spectrum analyzer for EMC pre-compliance testing:

- Low noise floor

- Wide frequency range (to cover your measurement range

- Peak, AVG, and Quasi-Peak detectors

- Adjustable RBW

- Programmable interface

- Reliable and within cal

- EMC software allowing you to:

- Account for the gains/losses of accessories,

- Apply limit lines, and

- Report notes, images, and results

(we’ve got another blog on this topic, in case you’re looking for more information on the benefits of using a Real-Time USB spectrum analyzer for emissions pre-compliance testing)

2. Antenna

The antenna you need will depend on the frequency range of your required measurement. Sometimes you will need multiple antennas because gain profiles vary with frequency. You may not be able to see your measurement if the gain of the antenna isn’t high enough and the measured signal is hidden by the noise floor. To boost the gain, you can use an external preamplifier or RF amplifier between the antenna and spectrum analyzer.

Here are the four most common types of antennas used for EMC compliance testing and their typical frequency ranges:

- Loop: 10 kHz – 30 MHz

- Biconical: 25 MHz – 300 MHz

- Log periodic: 300 MHz – 1 GHz

- Horn: 1 GHz – 26 GHz

3. Preamplifier

The preamplifier can help by boosting low level signals above the noise floor and improving the sensitivity of your measurement system. Make sure it operates over your frequency range of interest and has sufficient gain. Some preamplifiers have the added benefit of having a rechargeable battery, allowing you to make measurements when a power source is not available.

4. Antenna tripod

You’ll need a non-radiating tripod, preferably capable of raising, lowering, and rotating. Your particular standard may require a different kind of tripod. There’s a benefit to having a solidly constructed tripod made specifically for EMC testing if you can afford it, but you may be able to get away with constructing your own tripod out of wood and PBC piping.

5. Coaxial cables

You’ll need two RF cables. One for connecting between the antenna and preamplifier. One for connecting between the preamplifier and spectrum analyzer. They don’t need to be very expensive. As long as they operate over the frequency range you need, match the impedance of your antenna, and are stable while being bent you should be good. Cable lengths typically vary between 1 meter, 5 meters, or 10 meters.

6. Low-noise test environment

Unlike full EMC EMI compliance testing, pre-compliance testing does not require compliant test equipment or a semi-anechoic chamber (SAC) or EMC chamber. Today you can make relatively accurate results in your own office environment, conference room, or basement. While an actual chamber is always best, you can usually get away without it and save 10s or even 100s of thousands of dollars.

When selecting a test site, it is best to pick a location that will minimize external signal sources. Rural areas, conference rooms or basements are good because they minimize signals that might mask the DUT emission levels you are trying to measure. Other considerations for improving accuracy involve having a good ground plane and reducing the number of reflective objects around the test area. You can also implement measurement techniques which involve making an ambient noise measurement and subtracting it from your measurement.

7. Turn-table

You’re going to need to position your device or equipment under test in various angles depending on the EMC standard. Turn-tables designed for EMC testing can be purchased to allow easy and precise rotation. For those on a budget, a cardboard box positioned at the correct height and distance is a cost effective alternative.

Closing remarks

An in-house pre-compliance EMC test solution can help you pass full EMC compliance, saving you time and money. In this post I outlined the 7 items required in a radiated emissions pre-compliance EMC test. Unlike full compliance testing, pre-compliance testing does not require compliant test equipment or a semi-anechoic chamber (SAC) or EMC chamber.

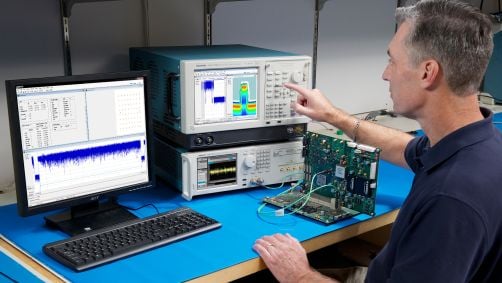

For achieving the highest accuracy possible, Tektronix’ EMCVu pre-compliance EMC software allows you to account for the gains and losses of your accessories in your measurement and perform ambient noise measurements automatically. The Tektronix RSA series of real-time spectrum analyzers are perfect additions to any pre-compliance EMC test solution. Visit the EMI and EMC Solutions page to learn more about the solution and available EMC instruments and accessories from Tektronix.

EMC Pre-Compliance Software in Action

All-in-one pre-compliance and debug solution for all real-time spectrum analyzers. Engineers now have a fast, easy, accurate and affordable way to determine if your new product designs are ready to submit to the test house. This video covers new EMCVu features, including: push button support for multiple standards, automated multiple measurement/multiple format reporting, ambient noise calibration and comparison, harmonic markers and faster scans using peak detector and spot measurements with quasi-peak and average detector failures.