與我們聯絡

與 Tek 業務代表即時對談。 上班時間:上午 6:00 - 下午 4:30 (太平洋時間)

請致電

與 Tek 業務代表即時對談。 上班時間:上午 8:30 - 下午 5:30 (太平洋時間)

下載

下載手冊、產品規格表、軟體等等:

意見回饋

Optimize Workflows with a Programmable Power Supply

A programmable power supply delivers precise, adjustable voltage and current with automated control for circuit testing, validation, and production. With advanced programmability and remote operation, it ensures accurate, repeatable measurements in R&D, manufacturing, and automated test environments. Watch the video to see how it enhances your testing workflow.

.,'

Keithley 2260B Series: High-Performance, Programmable

Power your tests with programmable voltage and current control in a compact benchtop design. With high accuracy, remote operation, and advanced sequencing, it’s built for automation and precision.

- Wide Power Range – Up to 800W total

- Programmable Control – Custom voltage and current profiles

- Remote Operation – Ethernet, USB, and GPIB connectivity

- Compact & Versatile – Ideal for R&D and automated testing

Find the Programmable Power Supply for Your Application

How Engineers Use Programmable Power Supplies

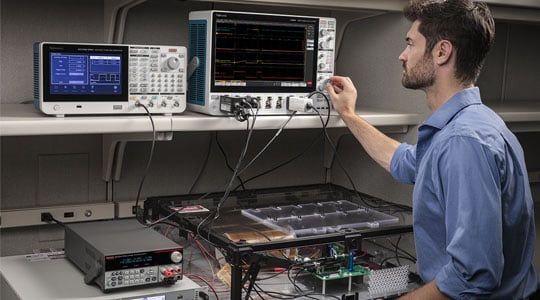

Automated Test and Validation

A programmable power supply integrates seamlessly into automated test setups, enabling engineers to run complex voltage sweeps, stress tests, and device characterization with precision and efficiency. Remote control and scripting capabilities reduce manual intervention and improve throughput.

Power Cycling and Stress Testing

With automated sequencing, a programmable power supply can simulate real-world conditions by cycling power, adjusting voltage profiles, and testing device limits. This is essential for reliability testing in industries like automotive, aerospace, and consumer electronics.

Battery Simulation for Device Testing

By mimicking real battery discharge profiles, a programmable power supply enables engineers to test battery-powered devices under controlled conditions. This ensures accurate performance evaluation for IoT devices, wearables, and portable electronics.

直流電源供應器量測技巧

設計的 10 個階段

設計可靠的電源供應器需要仔細的規劃、精確的測試和正確的工具。我們的電源供應器量測技巧指南將引導您瞭解電源供應器設計的 10 個基本階段,從元件選擇,到 EMI 疑難排解和最終驗證。無論您是最佳化效率、確保相容性或是解決問題,這些專家深入見解都將能協助您實現更好的效能和更快的上市時間。如果您正在選擇新的電源供應器,這些提示將引導您做出正確的選擇。因為最好的電源供應器不僅關乎規格,還與如何測試和改進您的設計息息相關。