By Gary Simonton

With the addition of USB 3.1 Gen 2 specifications and the reversible 24-pin Type-C connector USB’s dominance is the Consumer market place is further solidified. USB 3.1 Gen 2 delivers what the computing and mobile device industry wanted: fast 10 Gb/s transfer rates and a much more versatile, convenient and flexible connector.

Now, we’re all about implementing USB 3.1 Gen 1/Gen 2 and Type-C into as many designs as possible. And, as many of you are starting to discover, pushing the data rate up to 10Gb/s with Gen 2, and implementing the Type-C interface introduces a number of challenges compared to slow and steady USB 2.0. And, in case you’re not having enough fun with USB 3.1, be aware that USB 3.2 with 20 Gb/s data rates are right around the corner.

One of the most important steps for any USB designer is getting through compliance testing. Measurements like clocking with SSC, PHY measurements like jitter, voltage and eye mask, as well as LFPS timing and voltage swing measurements are all traditionally handled by automated compliance software in a compliance certification setting.

But what happens when one or more automated compliance tests fail? Here’s where the automated tests fall short – and a key reason why Tektronix offers comprehensive measurement capabilities that go well beyond what you can glean from automation. In fact, we offer a set of measurements that match up with what is required for compliance, but then give you powerful tools for in-depth analysis.

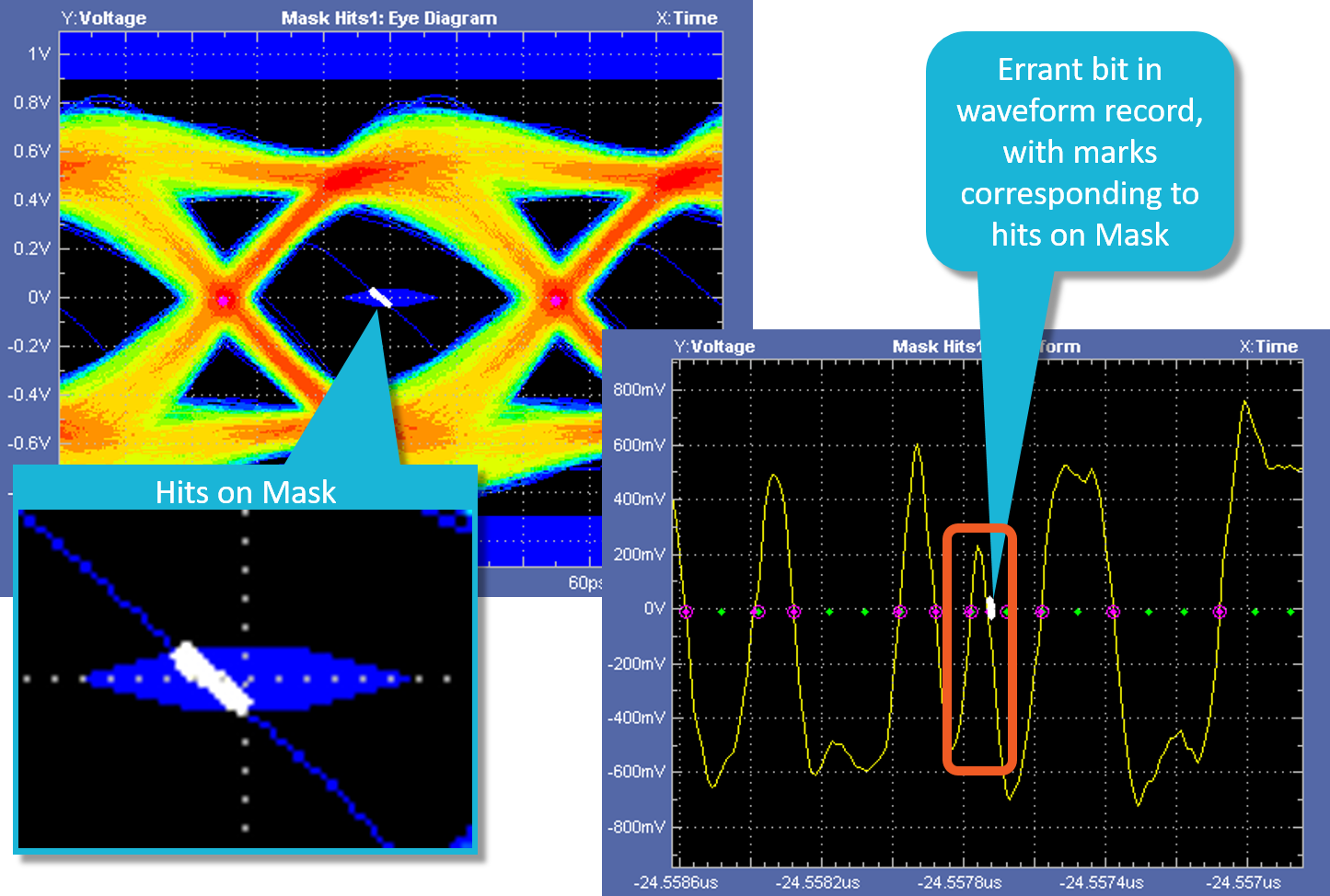

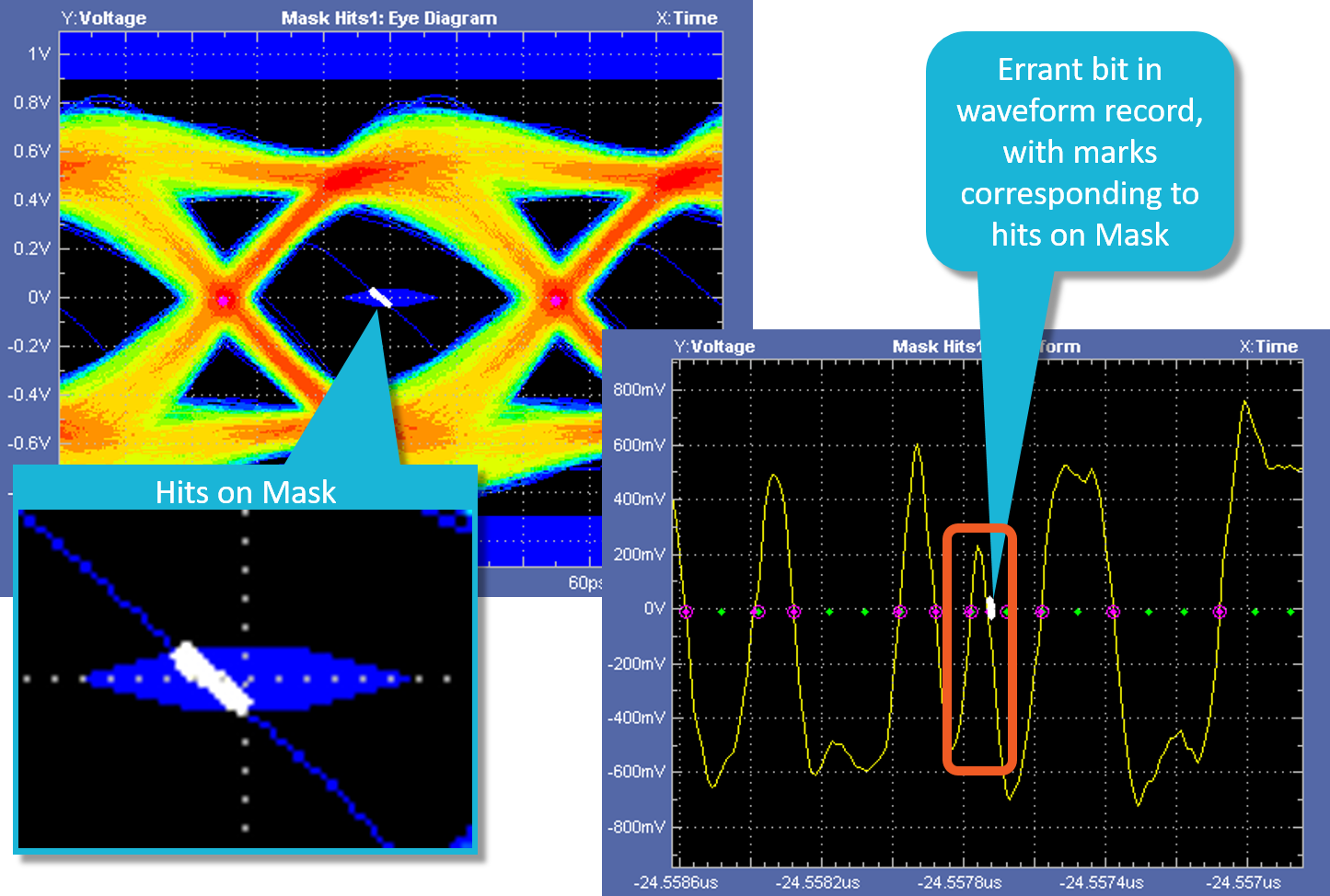

Our jitter and eye analysis software tool (DPOJET) provides the flexibility to single out specific measurements, and very accurately dig into the results to better understand the causes of failures or to determine how much margin exists in a given design. Debugging at this level is more important than ever given the complexity of the latest USB spec – and the faster speeds right around the corner.

To deal with this complexity, designers need better insight than what might be provided by only testing with an automated compliance solution. You need confidence beyond compliance, a way to dig down into a measurement failure or get to the root of issues that eat into the margins of your design.

For more detail on the requirements of the USB 3.1 specification, and the debugging capabilities we offer, take a look at the How to Debug USB 3.1 Gen1 and Gen2 Electrical Compliance Failures application note.