Part 1: 3 Market Trends Driving Automotive Innovation – Part One: Electrification and Batteries

Part 2: 3 Market Trends Driving Automotive Innovation – Part Two: In-Vehicle Networking

Part 3: 3 Market Trends Driving Automotive Innovation – Part Three: The Autonomous Vehicle

There are three major automotive trends, along with their unique testing challenges and solutions, that are driving the industry forward (pun intended). Those trends are vehicle electrification and batteries, the connected car and all the data that goes along with it, and last but certainly not least, automation, as in autonomous vehicles. These three trends are the focus of an on-demand webinar – The Future of Automotive is Electric – by Denis Solomon, Automotive Market Segment Manager here at Tektronix.

We’ll explore these three trends in this blog series, starting with the first market trend – electrification and batteries.

Automotive Electrification and Batteries

One of the biggest questions surrounding electric vehicles and batteries, is how to increase capacity and range on a single charge. There are KPIs around range, as well as KPIs around efficiency, acceleration, and fast-charging capabilities of batteries. One of the big trends that we are seeing in the marketplace today is lithium-ion batteries, but in the future we see a shift towards solid-state. This is driven primarily by solid-state batteries delivering a reduction in weight and an increase in density, and weight is a critical factor in the range of the vehicle.

Distance Vs Duration – What Is More Important for Battery Performance?

To increase the range on a single battery charge, the energy capacity needs to be increased, and there are two potential ways to do this. One, you can increase the number of battery cells per battery pack in a vehicle, but for such an approach the vehicle price and weight will increase as well – both not good for the range or for consumers. Two, you could increase the battery energy density measured in watts per hour, and in fact this is the path the industry is pursuing today.

Another approach that the market has also taken when they think about increasing battery range is evolving from the traditional cell-module-pack approach and skipping the module altogether – going from Cell-to-Pack directly, thereby reducing the weight of the vehicle. There is also a need for efficient energy conversion between what is the energy in the battery pack versus how efficiently it can be converted into physically moving a vehicle forward, which is the traction motor conversion efficiency.

The three main things being looked at in terms of battery improvements are increase in watts per hour, removing modules from the cell-module-pack and just skipping the module altogether, and efficient energy conversion. So, what's the biggest challenge of those three? Is there one that really stands out? First let’s look at battery attributes.

5 EV Battery Attributes

There are five primary attributes in a battery that need consideration:

- Their energy density

- Their cost

- How fast they can charge and power the vehicle

- Their longevity

- Their safety

The unique requirements of vehicle applications with respect to batteries include certain design considerations that are beyond those of consumer electronics. For example, automotive applications have more stringent technical requirements, such as the calendar life of a battery – they need to last for 10 to 15 years. Additionally, they need to be able to operate in a temperature range of between 30 to 52 degrees centigrade. Finally, they should cost less than a hundred dollars per kilowatt hour. It will be very challenging for a single battery technology or chemistry to perform at the needed levels for all five of these attributes.

The one drawback with lithium-ion batteries that stands out is that they tend to overheat and can easily be damaged at very high voltages. Over the lifetime of the battery, the energy storage capacity can also diminish. In future, when we switch to solid-state batteries, some of these tradeoffs will no longer be a concern.

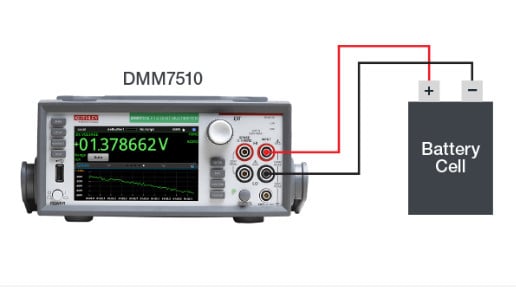

Measurement Challenges Around the Powertrain and Battery

On the powertrain side, the power and efficiency of an electric motor represents those decisive variables for evaluating and interacting with the battery storage, and they determine the mileage and the range of the electric vehicle. On the powertrain side, some certain measurements like mechanical measurements, DQ measurement, DQ zero measurements, as well as electrical measurements, are very important at determining their energy conversion efficiency. On the battery side of things, different test methods are developed for cell level, for module level, and at a system level. The same instruments that are used at a cell level can also be used at a system level once you pack them up. Some of the common measurements from the battery perspective that are relevant are around internal resistance measurement (that's a DC measurement), open circuit voltage (that’s a measurement of voltage at the terminals of the battery after some relaxation time). This is how we characterize the lithium-ion batteries used in automotive applications today. Others are leakage current, charge and discharge pulsing, to name a few.

Challenges Around Automotive Systems Measurements

Battery manufacturers are focusing on improving the lifetime of the battery and reducing the charge time and energy densities. So, when we think about a battery pack level, there are certain automotive tests that are more important than others and some of those are around busbar welding using Keithley 2400 graphical series SMU. When we put all these different batteries together, we need to check for incorrect welds which can generate excessive heat, and that can result in under-performance in a battery and even failure.

Then there are temperature and environmental tests, as well as self-discharge tests. Tests of the battery management system – an intelligent system that sits and monitors the state of charge and state of health of the battery pack – have standards that need to be met.

Compliance Tests Standards

To increase the EV market substantially, advances in battery technology alone are not sufficient. There are government regulations and standards which are critical. There’s also the need for a charging infrastructure to reduce driver anxiety over vehicle range. When it comes to Tektronix, we are members of a number of standards bodies and we actively participate in furthering the research in some of these emerging measurement sciences. For example, Tektronix is a member on the JEDEC committees, JC-70, 70.1, 70.2 work groups. And recently at APEC 2022, which is an industry consortium, we submitted a three-phase motor paper on DQ0 – a critical measurement looking at the mechanical performance of a motor using 5 series B MSO. New measurements are getting designed and specified and Tektronix is working closely with our industry partners and standard bodies to make sure we are measuring all of these areas accurately and reliably.

Battery Demand is Through the Roof

According to some industry estimates, the battery market is expected to grow at about 30% CAGR to 2030, reaching about 4,000 gigawatt-hour capacity – the equivalent of about 90 additional gigafactories in the next 10 years. Currently, the battery market is mostly dominated by China, which has the majority of real earth material needed for battery production.

The next automotive innovation trend we’ll explore is in-vehicle networking, so watch for Part Two of this series.