The asset management systems in place at many organizations are not able to deliver the data necessary to allow you to make good decisions about your business. We see it all the time, and if you’re in charge of calibration, you’ve likely lived it. A system of binders and hand-written documentation form the foundation of equipment calibration, creating gaps and redundancy. What’s more, if the person responsible for calibration should leave the organization, where does the company stand when internal quality or external regulatory audits are performed?

Using a manual or hybrid process for calibration management can lead to missed calibration cycles. Instruments that are left uncalibrated can offer less accurate data, resulting in compromised quality and product downtime. Companies found to be noncompliant with strict regulatory standards can incur heavy penalties and lose consumer confidence.

Accidents caused by missed calibrations and incomplete, missing or poorly documented processes can lead to legal fees and judgments as well as time consuming corrective actions that can cause irreparable harm to an organization’s reputation.

Requirements and Obstacles with Hybrid or Traditional Calibration Methods

There are five main areas of calibration management that must be attended to in order to maintain regulatory compliance and mitigate risk in most organizations. These areas are:

- Documentation

- Planning and Decision Making

- Organization

- Execution

- Analytics and Reporting

The work required to plan, schedule, document and track calibration intervals and procedures can add up to thousands of man hours per year depending upon the number of instruments a company has in service and the total number of periodic calibrations required. Even with a plan in place to tackle these calibration needs, organizations are faced with daunting obstacles that hinder most traditional or hybrid processes, including:

- Slow data collection and transfer processes

- Lost or misplaced calibration documents

- Inaccurate tracking

- Lack of effective analysis

- Inaccurate scheduling/missed calibrations

- Lack of connectivity with external data sources

- Transcription errors

- Lack of flexibility

- Insufficient security

Leverage the Cloud for Streamlined Calibration

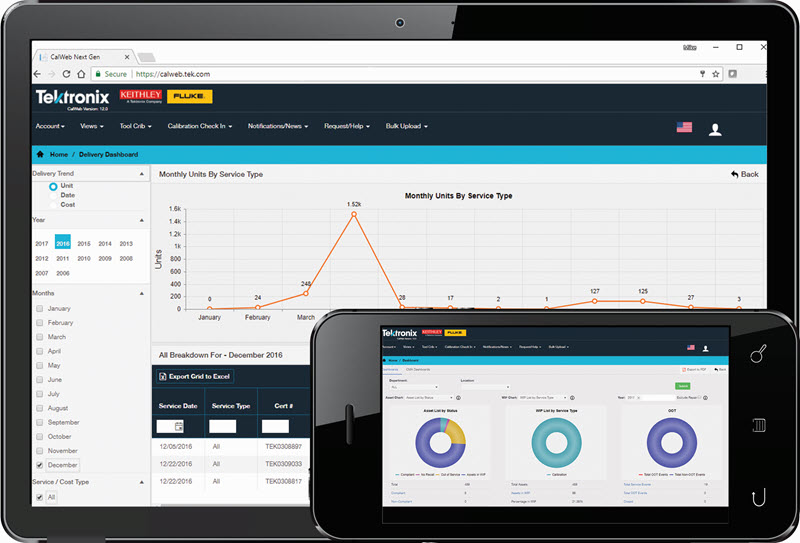

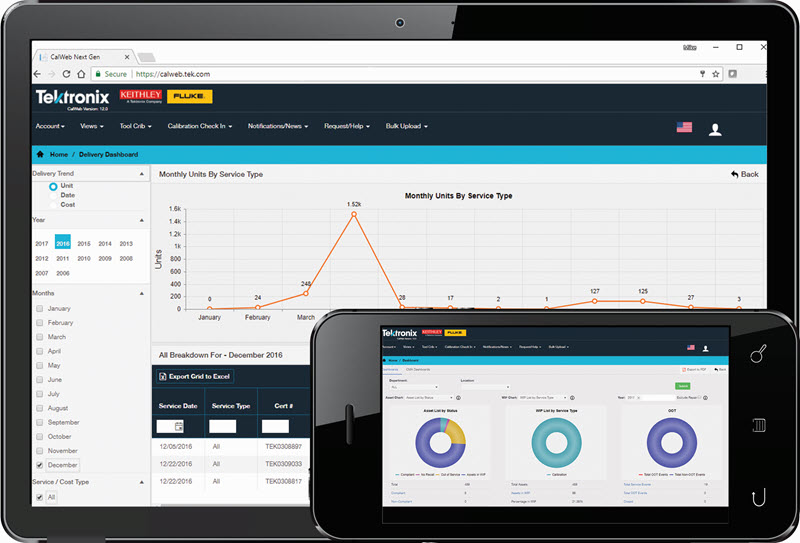

With a high quality, integrated asset management application such as CalWeb®, all aspects of running a calibration program are improved. Using a cloud-based asset management application, allows users to configure program features to their company's unique needs, providing the real-time visibility and scalability legacy systems lack. Bulk upload features allow companies to quickly and easily transfer existing data, eliminating the manual work associated with outdated transfer models. Increased production efficiencies, streamlined collaboration, and lowered risk thresholds are just a few of the many benefits of cloud-based calibration management.

CalWeb delivers the following four key features and benefits:

- Calibration Management - CalWeb provides automated document routing, approvals and escalations, eliminating the risk of missed calibrations. Users can view Tektronix-managed and internally-managed inventory in real time with the ability to drill down by asset number, calibration due dates, inventory location or service status.

- Document Storage - All points of the calibration process are documented in CalWeb including service history, loaner inventory, out of tolerance (OOT) and out of service instruments and calibration certificates. Document change controls ensure all documents and revisions are electronically tracked, signed and time/date stamped. CalWeb administrative tools allow system administrators to configure user rights and roles.

- Audit Support - CalWeb provides both standard and custom reporting features with automated conversion/ publishing capabilities. Electronically tracked and stored master lists, cycle times, revision history, and certificates allow for proactive system management and provide easy, accurate reporting and peace of mind when preparing for an audit or inspection.

- Risk Management - CalWeb collects and stores all asset data, including preventative maintenance records, equipment downtime and historical trend analysis. These features allow companies to identify, assess, and prioritize risk across product lines.

Every facility, regardless of size, can benefit from using our cloud-based asset management application, CalWeb, to manage its calibration program. Multi-tiered solutions and pricing are built around workflows so the application can be uniquely tailored to each customer’s needs. CalWeb's capabilities and benefits make it a natural fit for minimizing the time, cost and resources that go in to maintaining a complex calibration program.