與我們聯絡

與 Tek 業務代表即時對談。 上班時間:上午 6:00 - 下午 4:30 (太平洋時間)

請致電

與 Tek 業務代表即時對談。 上班時間:上午 8:30 - 下午 5:30 (太平洋時間)

下載

下載手冊、產品規格表、軟體等等:

意見回饋

EVSE 測試的重要性

電動車供電設備 (EVSE),通常稱為充電站,是從燃油引擎轉向電動車的關鍵組成部分。 電動車的普及性深受充電站的可用性 (運作時間和可靠性) 及其充電速度的影響。

EVSE 也必須遵循 IEC 61851 和 SAE J1772 等重要標準。

工程師分別在裝置、模組和系統層面上盡力透過更高的充電電壓來縮短充電時間,同時更致力於提高可靠性及維護安全性。智慧、靈活的測試解決方案讓設計人員能夠快速進行疑難排解並驗證其設計。

解決方案中有包含一個帶有複雜功率分析軟體的高性能示波器、一個可供您用來測量 EVSE 性能表現的高精度數位萬用表以及一個作為模擬高電壓、高容量放電電池之負載的雙向電源供應器。

檢視完整的工作台設定EVSE 測試設備和技術

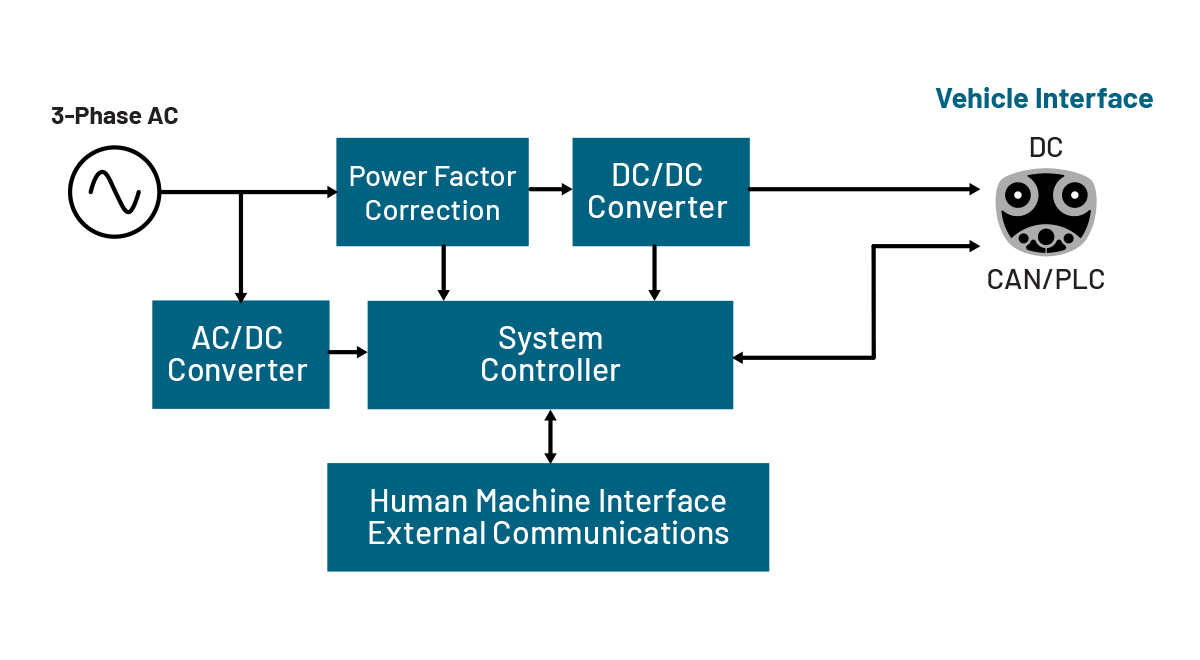

直流快速充電站區塊圖

EVSE 系統 - 功能模組

最先進的直流快速充電器可將電網的三相交流電轉換為高電壓直流電。此類系統由以下部分組成:

- 功率因數校正和交流/直流轉換器

- 直流/直流轉換器

- 控制系統和電源管理

- 使用者介面

- LAN/行動通訊

- 高電壓充電及通訊車用連接埠

這些模組都需要測試。 探索以下解決方案以瞭解更多資訊。

充電器前端的功率因數校正會使用切換功能來協調電壓和電流,以取得單位功率因數。它還可緩和所產生的電流,以減少公用事業設施的諧波負載。

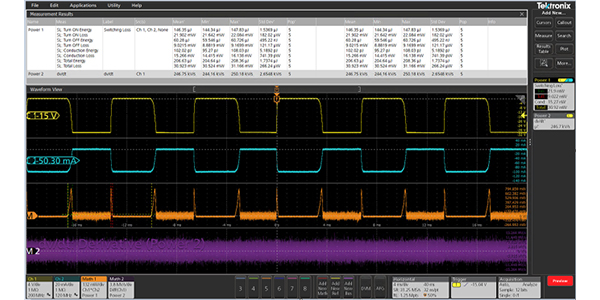

詳細的切換損失量測可量化電源轉換電路內的 FET 和 IGBT 損耗。

直流/直流轉換器和閘極驅動器分析

高功率直流/直流轉換器可在 PFC 區塊和車輛充電連接埠的電壓調節之間提供隔離作用。高頻變壓器常用於隔離和儲能。新設計多半會使用快速 SiC MOSFET 來提高效率和功率密度。

SiC MOSFET 的快速切換速度和電壓位準因為高頻寬和共模電壓而造成量測不易。EVSE 測試設備解決方案,包括具有光學隔離探棒和分析軟體的示波器,即使在高轉換速率、高共模電壓訊號下也能提供準確的量測結果。 包括:

- 峰值突波電流

- 過電壓/欠電壓保護

- 切換分析

- Miller 持續時間和電容

- 閘極電阻和充電參數

- 停工時間

- 切換損失

- 電路內部變壓器和電感器量測

- 控制迴路效能 (例如:PSRR 和增益/相位餘裕)

- 漣波和雜訊

- EMI/EMC 分析

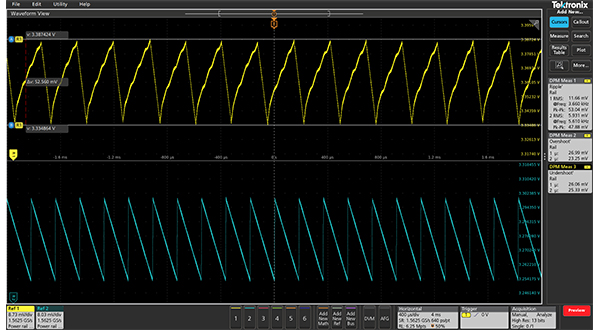

控制系統和電源管理分析

嵌入式控制器正是充電程序背後的控管總部。在充電期間,控制器會負責處理與車輛的通訊事宜、調節電力輸出並監控安全狀況。除此之外,控制器也會與使用者介面和數位網路進行通訊。

這類子系統一般來說包含處理器或 FPGA、時脈、電軌、記憶體系統及通訊 IC,而且通常會在低振幅的 GHz 訊號上運作。由於這些系統多半在條件惡劣的物理和電氣環境中運行,因此須具備高度的抗擾性和電源完整性。

驗證此類系統並加以除錯的的關鍵量測包括:

- 電軌漣波和雜訊分析

- 阻抗量測

- 電源供應時序

- 交流-直流轉換器

- 開關和定時分析

- 低端和高端開關間的盲區時間分析

- 變壓器和電感器的磁性分析

- 控制迴路分析

- 通訊訊號完整性

- EMI/EMC 分析

漣波量測可量化電軌上的雜訊。

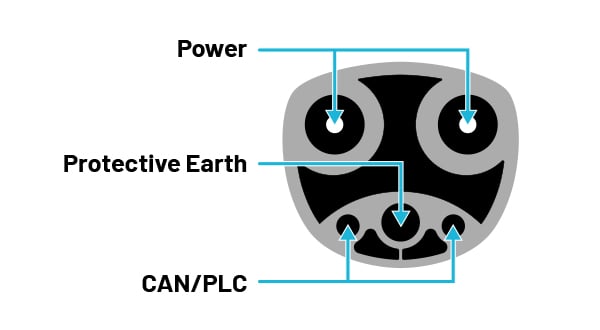

電動車介面會針對電源和保護接地使用兩個或更多大型針腳。較小的針腳則用於通訊,其中可能包括控制導引 (CP)、接近導引 (PP) 或控制器區域網路 (CAN)。

車輛介面量測和除錯

充電站和車輛電池管理系統之間的可靠通訊,對於管理充電過程以及維護安全而言至關重要。

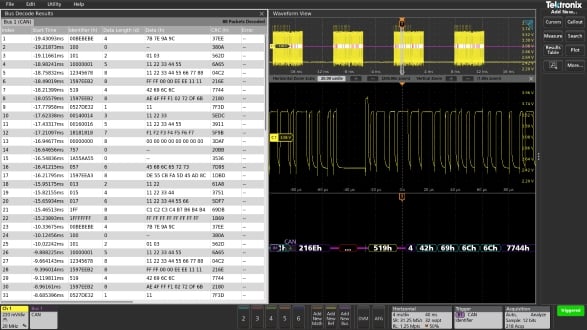

符合 IEC61851 的充電器中包含控制導引 (CP) 訊號。CP 訊號的工作週期會將最大可用電流從 EVSE 輸送到電動車。此訊號可使用示波器進行驗證。電力線通訊 (PLC) 也可以重疊在這條線路上,以便在充電過程中進行通訊。部分介面須仰賴 CAN 上傳輸的串列資料來進行 EVSE 和電動車之間的通訊。

在這兩種情況下,示波器對於檢查整個系統的訊號品質,以及尋找衰減、雜訊和錯誤終端都是不可或缺的工具。大多數 Tektronix 示波器均可配備 CAN 匯流排解碼和觸發功能,以顯示與其他系統層級活動同步的異動。

除了進行資料通訊之外,充電介面還必須將電流和電壓保持在規定的限制範圍內。舉例而言,充電器必須將線路的電壓瞬變、突波和下降對車輛直流輸出的影響限制在指定的位準和持續時間內。

驗證和偵錯 EVSE 的重要量測,包括:

- 通訊訊號完整性/雜訊

- DP 訊號的工作週期

- 系統定時

- 直流輸出雜訊

- 輸出穩壓

使用者介面和網路通訊分析

使用者介面裝置通常會透過 RS-232、SPI 或 USB 等標準串列匯流排連接到控制系統。網路通訊可為充電站業者和使用者提供重要資訊。示波器和主動式探棒非常適合用於使用者介面連接、LAN 和無線通訊的訊號與定時評估。Tektronix 示波器可支援超過 25 條從 RS-232 到無線 NFC 的串列匯流排解碼。

重要量測包括:

- 訊號完整性/雜訊

- 系統定時

- CAN 匯流排解碼

- LAN

- NFC 解碼

- 基頻射頻

- EMI/EMC 分析

CAN 匯流排解碼可用於顯示充電站和電動車之間的通訊。

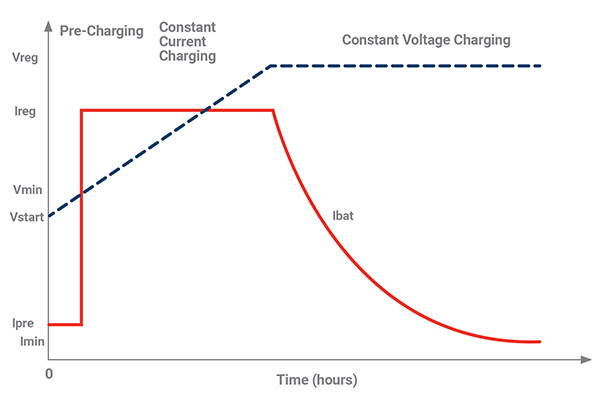

雙向電源供應器必須模擬的 EV 電池充電週期。

模擬電動汽車的電池

在測試 EVSE 時,各位會需要一個可以用來模擬放電電池的負載。雙向電源可以接收各種電壓位準與電源電流的電流以模擬電池的作用。雙向電源必須要能吸收各式各樣的電流,好模擬向已放電之電池傳送的高電荷電流,以及在接近完全充飽電狀態時所傳送出的低電荷電流。電源的額定電壓也必須要超過 800 伏特,以為電壓持續提高的電動車電池組充電。由於電動汽車的充電器支援更高效的充電速率,因此,用來測試這些充電器的電子負載也必須要能夠對應更高的功率。

高準確度和高穩定性這兩點能夠實現穩定且可反覆重現的電壓和電流位準,以確保所有的 EVSE 都能承受相同的負載條件。具有快速上升/下降時間的負載可以用來對充電器的負載調節實行最嚴苛的考驗。

由於 EVSE 提供高功率,電源需要過壓、過流和過熱監控,以確保對被測 EVSE 和電源本身的保護。 EVSE 測試通常在電腦控制下進行,需要強大的程式介面—USB、乙太網路、CAN、RS-232 和 EtherCAT 介面等。

EVSE 測試參考解決方案

為了引導您建立有效的測試設定 (包括根據您的需求量身打造 EA 電池模擬器),我們提供以下表格。 表格中列出了關鍵儀器、探棒和選項及其數量和描述,您可根據個人需求進行調整。

| 儀器/探棒/選項 | 數量 | 說明 |

| EA 10000 系列 | 1 | 雙向直流電源供應器和電池模擬器 |

| MSO56B | 1 | 5 系列 B MSO,具備 6 個輸入通道 |

| 選配 5-BW-500 | 1 | 500 MHz 頻寬 |

| 選配 5-SRAUTO | 1 | CAN、CAN-FD、LIN、FlexRay 匯流排解碼與觸發 |

| 選配 5-PWR | 1 | 功率諧波量測與分析 |

| 選配 5-SV-RFVT | 1 | 頻譜檢視射頻對比時間軌跡和觸發器,用於 EMI/EMC 疑難排解 |

| TCP0030A | 2 | 兩支電流探棒 |

| TMDP0200 或 THDP0200 | 2 | 兩支高壓差動式探棒 |

| TLP58 | 1 | 8 通道邏輯探棒,用於通訊協定和混合訊號分析 |

| TPP0500B | 1 | 六支被動式電壓探棒 (隨附於示波器中) |

| Keithley DMM6500 | 1 | 6 位半萬用電錶,用於進行精確量測 |

常見問答集

為何電動車和 EVSE 系統之間的通訊測試如此重要?

- 強化使用者體驗:有效的通訊測試可確保電動車 (EV) 和充電站能夠密切地相互配合,進而為電動車車主提供順暢無憂的充電體驗。這不僅是影響使用者滿意度的一大因素,也是信賴充電基礎架構與否的關鍵所在。

- 安全性和可靠性:通訊測試有助於偵測並處理充電系統中潛在的安全問題和漏洞。透過識別並緩解風險,此測試能協助提高電動車充電的整體安全性和可靠性。

- 互通性:互通性測試確保不同的電動車型號和充電站能夠有效地進行通訊。這對於建立開放且使用無礙的電動車充電生態系統而言至關重要,並可讓使用者在其中選擇各種充電選項。

- 標準合規性:許多國家和地區皆針對電動車充電的通訊協定訂有特定標準。如能在測試中遵循這些標準,充電系統即能符合法規要求。

用於驗證電源轉換器的常見測試有哪些?

- 效率測試:針對電源轉換器和太陽光電逆變器的效率進行測試,以評估此類裝置轉換電能的效率。若要減少能源浪費及確保最佳系統效能,高效率正是關鍵所在。

- 安全檢查:安全測試可評估電源區塊是否具有潛在風險,例如過熱、短路或電氣故障。確保這些元件的安全性對於防止意外和系統故障是很重要的一點。

- 效能驗證:效能測試可評估電源區塊在各種條件下的運作能力,包括負載變化和環境因素等。這有助於確保可靠且一致的效能表現。

- 電磁相容性 (EMC) 測試:EMC 測試可檢查電源區塊是否會產生電磁干擾,以及是否不受外部干擾。在有其他電子裝置的情況下,務必遵循 EMC 標準以利順暢運作裝置。

- 溫度剖析:監控溫度是防止過熱的關鍵,如過熱可能會導致元件損壞。溫度剖析可識別潛在的熱能問題並有助於維持安全的運作狀態。

EVSE 測試設備有哪些應用?

- 符合性驗證: EVSE 測試設備為用於嚴格驗證電動車供電設備 (EVSE) 是否符合國際充電標準。 在驗證中需要評估電網互動、通訊協定、電壓位準和電流位準,以及是否符合安全標準。

- 互通性評估:測試設備也用於評估各種電動車型號和充電站之間的相容性。 互通性測試對於確保所有使用者的順暢通訊和可靠的充電體驗至關重要。

- 安全保證:進行安全測試是為了測試保護使用者和設備免受衝擊或損壞的系統,包括隔離、接地和接地故障斷路器,例如 RCD 或 GFCI。

- 效能最佳化:EVSE 測試設備有助於最佳化充電站的效能。 工程師可利用這些工具來提高效率並減少充電時間,同時確保安全性和可靠性。

EVSE 測試設備如何用於研發?

在 EVSE 設計過程中,工程師會使用測試設備來啟動並驗證子系統和整個系統:

- 模擬各種充電情境:工程師會使用 EVSE 測試設備來模擬各種充電情境,並在其中模仿不同的車型和充電條件。

- 監控通訊:工程師會監控 EVSE 和模擬車輛之間的通訊,藉以檢查訊號完整性或時序是否有任何異常情況。

- 量測功率輸出:工程師還將量測不同負載條件下的功率輸出,確保 EVSE 能夠安全且有效率地提供所需的電力。

- 偵錯和驗證:設計人員會在設計過程中使用測試設備來啟動原型並驗證新產品的效能。

- 驗證可靠度:工程師最後會驗證充電站在各種環境條件下,是否能可靠地為各種電動車提供服務。

電力電子裝置和電動車系統領域的一般量測為何?

- 電壓量測:電壓量測對於評估電力電子裝置和電動車系統內的電壓位準至關重要。此類量測可針對電路行為提供洞察資訊,並確保所有電路均在安全的電壓限制內運作。

- 電流量測:電流量測可量測電力電子裝置和電動車系統內的電荷流量。準確的電流量測對於監控功耗及確保電氣元件安全與否至關重要。

- 溫度監控:溫度監控是防止過熱,以及確保電力電子裝置和電動車電池系統使用壽命的一大功臣。此功能有助於維持安全又高效的運作狀態。

- 功率因數 (PF) 分析:功率因數量測可評估電力電子裝置中的電源轉換效率。高功率因數代表能有效利用能源,進而減少浪費和能源成本。

- 諧波分析:諧波是電子波形中造成干擾的失真情形,並因而影響系統效能。諧波分析有助於識別並減輕這類失真問題,以維護電源品質。

- 效率量測:效率量測可評估電力電子裝置和電動車系統中的電源轉換及利用效率。高效率不僅是減少能源浪費不可或缺的一環,更是運作能否符合成本效益的關鍵。

- 電壓漣波:電壓漣波或波動會影響敏感型電子裝置的運作。監控並大幅減少漣波對於確保穩定可靠的系統效能而言非常重要。

- 充電狀態 (SoC) 量測:SoC 量測對於電動車的電池管理特別重要。這類量測可判定電池中的可用電量,進而提供準確的範圍估計資訊並防止過度放電。

- 直流匯流排電壓量測:監控直流匯流排電壓可確保系統穩定性並保護關鍵元件,例如逆變器和電源轉換器等。這對於安全可靠的運作至關重要。

- 能源消耗監控:量測能源消耗可深入瞭解能源的使用效率,進而促成電動車和電力電子應用的最佳化並節約成本。這不僅能協助有效管理電力使用狀況,還能找出需要改進的領域。

- 隔離測試:隔離測試可確保電氣安全性並有助於防止電氣危害。此測試可確認電路和元件是否正確隔離,而且沒有潛在故障問題,以確保安全的運行狀態。