Свяжитесь с нами

Живой чат с представителями Tektronix. С 9:00 до 17:00 CET

Позвоните нам

С 9:00 до 17:00 CET

Загрузить

Загрузить руководства, технические описания, программное обеспечение и т. д.:

Обратная связь

Sustainability in electromobility is a major challenge

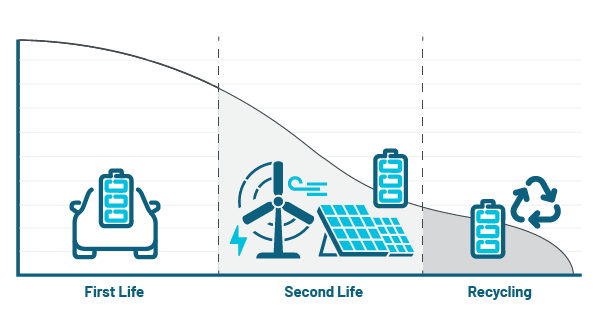

To make electromobility sustainable, second-life concepts and efficient recycling of lithium-ion batteries and lithium-ion polymer batteries will play a key role in the very near future. Completely new industries and companies are emerging to take on this task.

Optimize your battery recycling

Delivering high-efficiency energy recovery and battery testing systems that optimize every stage of the battery recycling process.

For second-life applications, our bidirectional DC power supplies enable precise testing and reconditioning of used batteries, returning over 96% of energy to the grid. When it’s time for final recycling, our regenerative electronic loads ensure safe, complete battery discharge while recovering residual energy—reducing risk and energy waste.

These technologies help recyclers lower costs, improve safety, and support a more sustainable, circular battery economy.

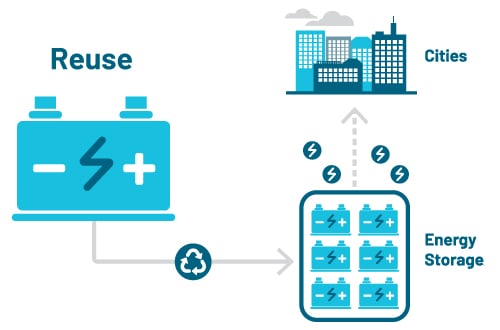

Second-life use

Bidirectional DC lab power supplies test the remaining capacity of your batteries

The primary goal is to find a second use for the batteries from electromobility after they have been used in the vehicle (second-life use). For example, as energy storage for solar power or wind energy. When testing the remaining capacity, the battery is first fully charged and then discharged in a controlled manner. The capacity (SOC) and state of aging (SOH) are measured and the energy is fed back into the power grid with an efficiency of over 96%.

Bidirectional programmable DC power supplies

For this application, it makes sense to use bidirectional laboratory power supplies for further investigation. With only one device, it is possible to test whether older batteries from electrically powered vehicles can still be used in other applications. If these applications are predominantly static and if the residual capacity is sufficient, these batteries will find their second-life use e.g. in stationary energy storage systems.

In this test, the battery is first fully charged with the bidirectional power supply and then discharged in a controlled manner with the same device. The capacity (SOC) and state of aging (SOH) are measured and the energy is fed back into the power grid with an efficiency of over 96%.

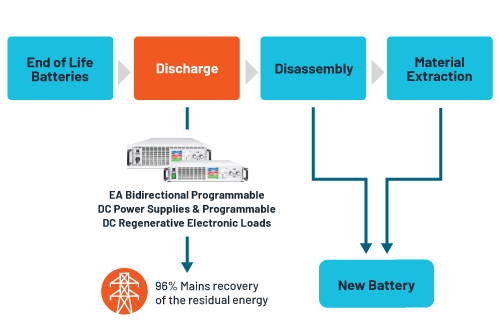

Final recycling

Efficient, safe and sustainable

In order to make the recycling or reusability of lithium-ion batteries economical, all processes must run with maximum efficiency. Since lithium-ion batteries and lithium-ion polymer batteries should never be fully discharged during their service life, it can be assumed that most batteries end up for disposal with residual capacity. Before the batteries are subjected to the actual recycling process, they must be fully discharged.

Electronic loads with mains feedback for the complete discharge of your accumulators

After the second-life cycle, the rechargeable batteries are subjected to final recycling. This process attempts to recover as many components of a lithium- ion battery as possible as raw material for new batteries. Before the batteries are disassembled into their individual parts, they must be fully discharged. This is done in order to avoid the risk of contact-hazardous voltage or fire and to use the residual energy still stored in the battery.

EA Elektro-Automatik’s regenerative electronic loads are a very efficient solution for this purpose.

Advantages of bidirectional programmable DC power supplies

High efficiency and higher safety when testing the battery capacity

Bidirectional programmable DC power supplies from EA Elektro-Automatik ensure the maximum possible charge and discharge of the batteries. With precise tests, detailed data about the remaining capacity is provided for the DUT.

Economy through time savings

The time saved in charging and discharging the lithium-ion batteries using the high input powers of up to 15kW in 3U enclosures or 30kW in 4U enclosures increases cost-effectiveness. In addition, the devices can be combined to form high-performance switchgear cabinet systems with a total output of up to 1.92MW.

Elektroautomatik’s 60kW 6U bidirectional power supplies support parallel operation up to 3.84MW, offering efficient energy recovery and high-throughput testing in compact, modular configurations.

Amortization through power regeneration

The bidirectional programmable DC power supply from EA Elektro-Automatik takes its energy from the connected battery during the discharge process and converts it into AC voltage with an efficiency of up to 96%. This is then fed back into the local power grid and reused, thus amortizing the purchase price via reduction of electricity costs.

High flexibility in use

Versatile and flexible: Due to true autoranging capability of the device series from EA Elektro-Automatik, battery storage systems with different system voltages can be charged and discharged with only one bidirectional programmable DC power supply. For example, full power is available with one device for both a 400V and 800V system.