Introduction

Photovoltaic (PV) cells convert sunlight directly to electricity. Fabricated from a wide variety of materials using many different processing techniques, these devices are used for terrestrial power generation, as well as commercial, military, and research space power applications.

PV cell characterization involves measuring the cell's electrical performance characteristics to determine conversion efficiency and critical equivalent circuit parameters. It is an important tool for R&D and production of cells and photovoltaic arrays. This application note describes how to use the Keithley Model 2420 High Current SourceMeter® instrument to measure the current-voltage (I-V) characteristics of PV cells.

With the introduction of SMUs (Source-Measure Units), configuring device characterization systems that once required a rack of electronic equipment, including programmable power supplies, digital multimeters, and scanners, has been simplified significantly. The Model 2420's ability to source/sink up to 3A with 0.5% accuracy or better and its low noise, high impedance, repeatable DMM offers a cost-effective alternative to using expensive, high power programmable power supplies for PV cell characterization.

The Model 2420 offers 10μV resolution on the 2V range, which is sufficient to measure the I-V curve of any single junction cell. The 20V range offers adequate resolution (100μV) for multi-junction cells and small arrays, where the open circuit voltage may exceed 2V. The Model 2420's low current measuring capability, with 10pA maximum resolution on the 1mA current range, is sufficient for virtually all dark I-V applications.

Test Description

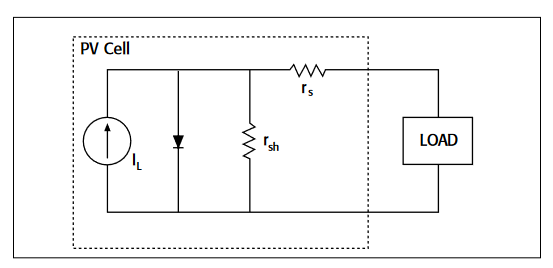

A PV cell may be represented by the equivalent circuit model shown in Figure 1, consisting of a photon current source (IL), a diode, a series resistance (rs), and a shunt resistance (rsh).

The series resistance (rs) represents the ohmic losses in the front surface of the cell and the shunt resistance (rsh) represents the loss due to diode leakage currents. The conversion efficiency (η) is defined as:

η = Pm/Pin

and the fill factor (FF) given by:

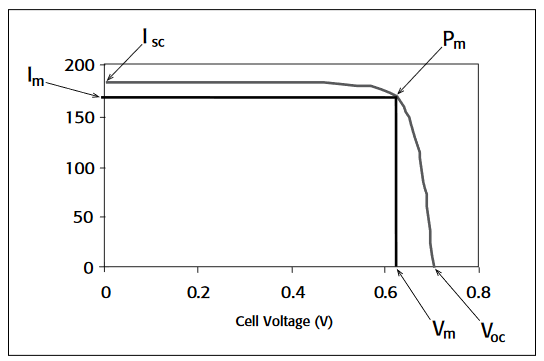

FF = ImVn/IscVoc

where Pin is the power input to the cell, Voc is the open circuit voltage, Isc is the short circuit current, and Im and Vm are the maximum cell current and voltage respectively at the maximum power point, Pm = ImVm. Figure 2 illustrates the typical I-V characteristics of an Si PV cell, showing Im and Vm at the maximum power point.

Critical PV cell performance parameters, such as the equivalent cell shunt and series resistance and the electrical conversion efficiency and fill factor, may be determined from I-V measurements. The cell must be maintained at a constant temperature and a radiant source with a constant intensity and a known spectral distribution must be used.

Forward Bias I-V (Illuminated)

This test involves generating the forward biased I-V curve between the two points (V1 = 0, I1 = Isc ) and (V2 = Voc, I2 = 0). The parameters Voc and Isc can be directly determined from the curve and Im, Vm, Pm, FF, and η are easily calculated. Additional analytical techniques may be used to determine rs and rsh.

Reverse Bias I-V (Dark)

The reverse bias I-V curve test is performed in the dark between 0V and the level where breakdown begins to occur. In this region, the slope of the current-voltage characteristic can be used to estimate the shunt resistance (rsh).

Test System and Configuration

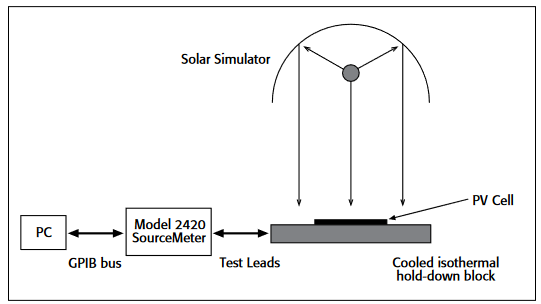

Figure 3 illustrates the measurement configuration for generating the illuminated forward bias I-V characteristics, using a Model 2420 and a 4-wire connection to the cell to minimize measurement lead resistance errors. A solar simulator provides appropriate illumination for the cell and a cooled, vacuum hold-down chuck secures the cell and provides isothermal test conditions.

The series resistance (rs) of a PV cell is low, typically <1Ω for cells designed for operation at 1 sun and <0.1Ω for concentrator cells. As a result, direct contact to the cell bus bar with specially designed 2-point probes is essential to obtain accurate forward bias I-V measurements.

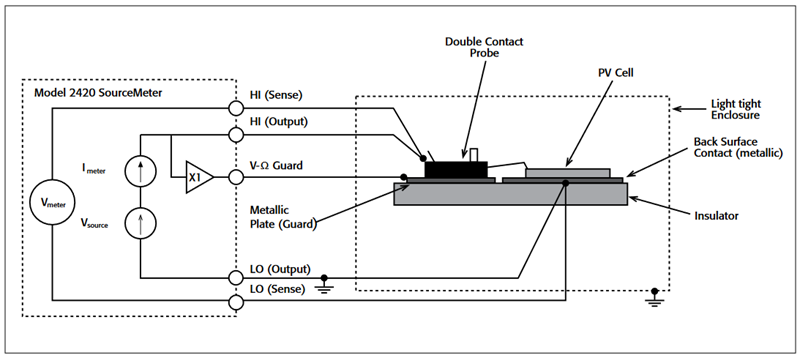

Figure 4 is a schematic of a measurement configuration to generate the dark reverse I-V characteristics. If the dark reverse currents to be measured are >1μA, the unguarded 4-wire configuration will provide accurate measurements. For dark reverse currents <1μA, stray leakage currents in cables and fixturing may create errors and noise in measurements. Two methods can be used to reduce or eliminate these sources of error. The first requires using high resistance materials when constructing the test fixture and keeping the fixture free of contaminants. The second method employs the Model 2420's built-in guard circuitry.

In Figure 4, the V-Ω guard output of the Model 2420 is a low impedance source at nearly the same potential as the high impedance point, HI (output). Guarding is used in this circuit to ensure the contact probe housing remains isolated from the circuit. The probe housing is constructed from insulating materials; however, contamination may cause a breakdown in resistance and introduce measurable stray currents. The guard plate under the probe, at approximately the same potential as the probe on the top contact of the cell, ensures no current can flow through the probe housing, so the current measured flows through the cell.

Programming the 2420 for Cell Characterization

Any of the example programs on Keithley's web site that carry out an I-V sweep would be an excellent starting point. Examples are available in a number of programming languages at www.keithley.com

Our LabTracer application is an additional software resource. LabTracer was developed in TestPoint but is provided as a runtime. Therefore, TestPoint is not required to run LabTracer.

Equipment List

The following equipment is required to assemble a PV cell characterization system:

- Keithley Model 2420 SourceMeter instrument

- IEEE-488 interface such as the Keithley KPCI-488

- Source illumination (solar simulator)

- Temperature-controlled hold down chuck/test fixture

- Keithley 7007-x IEEE-488 Interface cable

- Test leads (4-wire) and 2-point adjustable contact probe(s)

Alternative Solutions

The Model 2420 with 3A capability is the most commonly used instrument for photovoltaic cell characterization. However, Keithley offers several other SourceMeter instrument options for this application. If all the tests to be performed require less than 1A output, the Model 2400 can perform the same tests as the Model 2420 at a lower cost. For testing needs beyond 3A, the Model 2440 offers 5A output capability. For devices where the dark reverse current is <1nA, the Model 238 Source-Measure Unit offers guarded current measurements with resolution as low as 10fA and the ability to source up to 1A, so it may be substituted for a SourceMeter instrument.