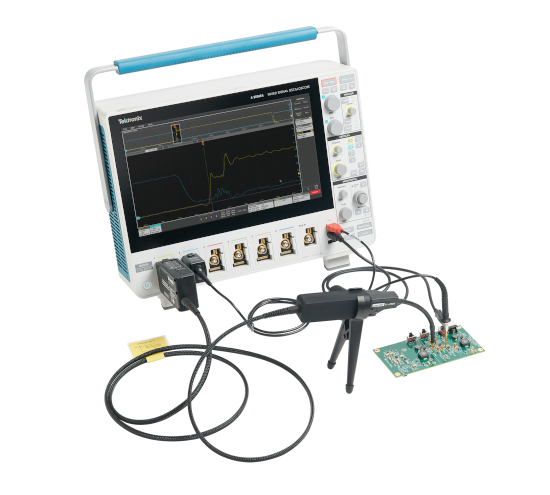

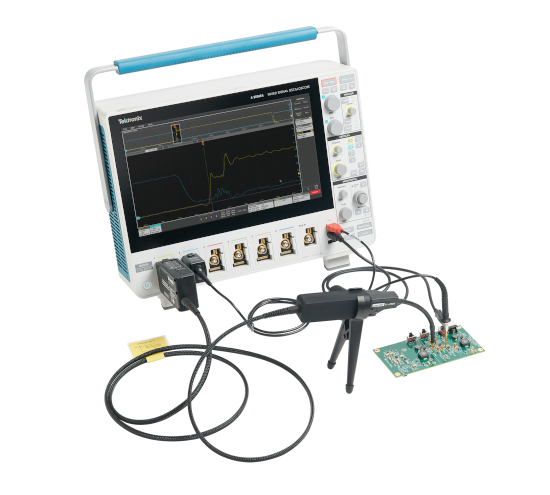

In this article, we will explore in detail some best practices to follow when handling Tektronix's isolated differential probe, also known as IsoVu™ probes.

What is IsoVu?

IsoVu is the brand name used to describe Tektronix's isolated differential probes. Generation One (TIVHx/TIVMx) was released several years ago, and Generation Two (TIVPx) came out more recently. IsoVu probes were originally designed for wide bandgap semiconductor testing of gallium nitride (GaN), silicon carbide (SiC), and other similar devices. They are also well suited for a wider range of applications – wherever you wish to make a relatively small differential voltage measurement in the presence of an extremely large common mode interference.

Best Practices to Operate and Handle IsoVu Probes

The following are some of the best practices to be followed during the operation, as well as handling of the IsoVu probe and probe tips.

Let it warm up

There is a warm-up period recommended for any active differential probe. This allows all the components within the probe’s system to warm up and is typically seen on the scope as a DC offset in the waveform captured. A slightly longer warm-up period than usual, of about 20 minutes, is recommended for an IsoVu probe, due to its size and the complexity of the fiber optic transmitters and receivers inside. After this warm-up period, the user simply needs to press the SELF CAL button on the probe’s compensation box or in the scope’s channel badge. The probe will then perform a self-calibration and auto zero routine, and the DC offset will be removed. If the ambient temperature around the probe changes by +/- five degrees Celsius, a warning displays on the scope screen. It’s a good practice to recalibrate the probe when this happens.

Keep wires short for unplanned test portions while using the MMCX tips

Tektronix offers a variety of tips for IsoVu probes. The best performing one in terms of common mode rejection is the MMCX or Micro-miniature coaxial tip, which provides a shielded barrel-style connection, for voltages just under 250 V. These are mostly used for planned test points. However, there will be cases when unplanned test points need to be added to accommodate for this receptacle. The Tektronix website offers detailed videos on how to use MMCX connectors to create unplanned test points for both surface mount and through-hole versions. Keep in mind to make the wires coming off the MMCX tips as short as possible when adding them to surface mount connections.

Handle probe tips with care

Probes in general can have some of the most damaging use of any piece of test and measurement equipment. They tend to get thrown into drawers, get subjected to voltages and currents that are beyond their capability, get mechanically stressed from a flexibility perspective, and more. IsoVu probes and probe tips are designed to achieve the highest performance in common mode rejection, making their handling crucial to their performance.

To achieve high performance in the common mode rejection of which IsoVu probes are capable, we shield the entire cable with a conductive metal mesh from end to end on the probe tip, allowing us to ground out any EMI that may be coupling around the measurement or the probe tip. If that mesh is damaged or disrupted in any way, it can cause failure. Note that the minimum bend radius of the probe tip cable is 2.0 inches (5.1 cm). So, it’s important to keep in mind that even though these tips are flexible, they can be subjected to immense mechanical stress and strain, so they need to be handled carefully and not just thrown into drawers or unduly strained beyond their capacity.

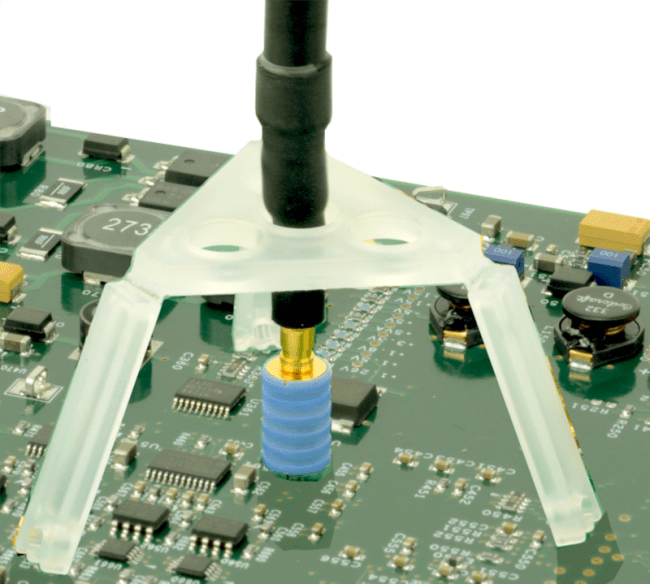

It is also important not to place any strain on the MMCX surface mount connections on the board. Be careful in the way you attach the probe tip into the MMCX barrel receptacle, and use the tip tripod support accessory when necessary (Tek part number 352-1170-xx). You may want to also consider a way to hang the probe tip vertically above the test point so that little to no horizontal strain is placed on the receptacle.

Use different tips, adapters, and connectors for different applications

A shielded connection like MMCX is usually preferred when it comes to performance, but it might not be ideal for every application out there. So, we’ve provided a variety of different leads and adapters to satisfy your needs. For instance, we offer some different types of connectors including the standard square pin with 0.1-inch (2.54 mm) spacing and wide square pin connections with 0.2-inch (5.08 mm) spacing for the 2,500 V tips, adapters to convert MMCX to square pin, tripod supports to reduce horizontal stress on the probe tip, or the connection point soldered to the PCB. We also offer a variety of other style tips that can adapt from either the MMCX or square pin standard, like IC grabbers, banana jacks, alligator clamps, and more. See our complete selection guide for IsoVu tip accessories.

Applications of IsoVu Probes

Some of the applications in which IsoVu probes can be used and has made a name for itself are as follows:

Wide bandgap material testing

Here, IsoVu probes provide a clean image of the exact signal you’d expect to see – perhaps even the exact signal you for which you simulated. This is because it nullifies the effect of common mode voltage, which typically distorts waveform or characterization capabilities when you try to do the measurement with a traditional differential probe. The resulting captured waveform allows for developers to make accurate adjustments to dead-time measurements to lead to the improved efficiency when using GaN and SiC.

Power rail measurement

In this application, IsoVu probes can reject some of the common mode noise that is apparent in the environment around the probe. This is useful if, for example, you’re trying to determine the effect of the common mode emissions in the environment on the power rail. Using traditional probes, you might experience ringing, but with IsoVu probes, the ringing doesn’t occur.

High-speed serial applications

These are well-suited for IsoVu probes in situations where high common mode voltage is masking over low voltage serial buses. Here, IsoVu probes can help determine the source of any ringing that happens, validating whether it’s coming from a common mode source or not.

Floating measurements

These are otherwise made with scopes that are either ungrounded or have the insulated tape around the grounding probe. Here, IsoVu probes can help make the process safer through a galvanically isolated type of probing system. This would also include high surge, transient EMI compliance, or debug applications.

Automotive applications and others

Sometimes, in these applications, the measurement being made is further away from the scope. IsoVu probes are highly suited to these applications because we offer a ten-meter fiber optic cable option for IsoVu probes, which will allows you to take measurements from far away from the scope operator. The small diameter of the TIVPx probe head also enables users to funnel the probe through a port hole and inside of dyno chamber.

In summary, there are several best practices to keep in mind while using Tektronix IsoVu Isolated Differential Probes. They include letting the probe warm up and handling the flexible probe tips with care, as well as using different tips depending on the application rather than only considering the MMCX tip. Visit our website for more information on IsoVu isolated probes and specifications.