HALT/HASS Applications

The rapid growth in many electronic sectors has required an increase in production of critical sub-systems, such as switching power supplies, DC-toDC converters, telecommunication devices, and related assemblies. Frequently, these sub-systems require highly accelerated stress screening (HASS), or “burn-in” testing, to make sure they perform reliably for their intended service lives in the finished product. (A glossary at the end of this white paper explains commonly used terms and acronyms associated with HALT/HASS testing.)

Since hundreds of products may be simultaneously aged and monitored during HASS, the challenges for measurement equipment are the large number of test channels needed and the immense amount of electrical noise that can be produced (e.g., by switching power supplies). But even before HASS testing can take place, similar highly accelerated life testing (HALT) is performed during product development with the aim of shortening time to market and ensuring a much more mature product at launch. Meeting this challenge requires careful design and operation of test system hardware and software to achieve high throughput and accuracy. As always, size and cost of test equipment are major issues. These concerns cut across a wide range of disciplines, involving product development and production engineers, QC/reliability engineers and managers, production test engineers, and related technicians.

Relationship Between HALT and HASS

When properly implemented, highly accelerated life testing (HALT) and highly accelerated stress screening (HASS) quickly uncover problems associated with product design and production. Both rely on techniques that shorten the time required to identify potential causes of failure. This is done by applying much higher stresses than exist in actual product use, which forces failures to occur in significantly less time than under normal conditions.

In HALT, temperature and vibration stress conditions are used during product development to find weak spots in the product design and its planned fabrication processes. Other test stimuli may include humidity, thermal cycling, burn-in for a specified period of time, over-voltage, voltage cycling, and anything else that could logically expose defects. This requires only a few units and a short testing period to identify the fundamental limits of the technology being used. Generally, every weak point must be identified and fixed (redesigned) if it does not meet the product’s specified limits.

In production, HASS employs high stress, frequently well beyond the qualification level, but not at the extreme stress levels conducted in HALT tests. Appropriate proof-ofscreen[1]techniques must be used to protect good product, and HASS usually is not possible unless comprehensive HALT was done earlier (because fundamental design limitations will tend to restrict HASS stress levels).

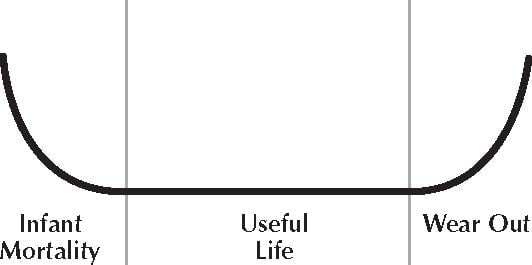

The fundamental proposition behind HALT/HASS is that if a product and its manufacturing processes are properly designed and verified with HASS, then production operations should turn out reliable units. Consequently, if HASS turns up units failing prematurely in production, then this usually is a result of improper manufacturing practices and/or random part failures. Typically, a population of products will exhibit reliability characterized by a bathtub shaped curve (Figure 1) with three distinct failure rate regions. The first region is the “infant mortality” section of the curve, which has a decreasing failure rate and is associated with built-in (i.e., not designed-in) defects. These are the types of defects that often can be identified by HALT testing. The amount of time required for a subsequent HASS test is determined by the width of the infant mortality region of the reliability curve. In general, the higher the stress, the sooner the failures, the narrower the infant mortality region and the shorter the HASS test period.

[1] A proof-of-screen is used to verify that HASS test limits (derived from HALT) will catch production defects without damaging good product.

Figure 1. Product reliability curve.

HALT/HASS Test Profiles

As alluded to earlier, HALT and HASS test profiles include temperature and vibration as well as other stimuli that reveal a wide range of problems. Common examples and their test objectives are described below.

Temperature Profiling:

• Determine the minimum and maximum product operating temperature limits

• Accelerate the aging process of the device under test (DUT) by applying extreme temperatures

• Test the DUT under various climatic and pressure (i.e. altitude) conditions

• Burn-in the DUT under elevated temperatures at a high duration rate

Humidity Profiling:

• Determine the effects of high/low humidity on the DUT (high humidity can cause corrosion, whereas low humidity can lead to electrostatic discharge damage)

• Find latent shorts on PCBs related to humidity (typically due to ion migration)

• Accelerate the aging process of the DUT by applying extreme humidity conditions

• Test the DUT under global humidity and pressure (i.e. altitude) conditions

Vibration Profiling:

• Determine the maximum product operating vibration levels

• Find mechanical defects early in the work-in-process cycle

• Simulate global transportation conditions on the DUT

The parameters measured with any of these HALT/HASS profiles can be any number of signals that indicate whether or not the product is functioning properly. The measured signals may range from DC values to high-frequency RF variables. In some cases, a stimulus must be applied to the DUT and its response measured.

Test Equipment Considerations

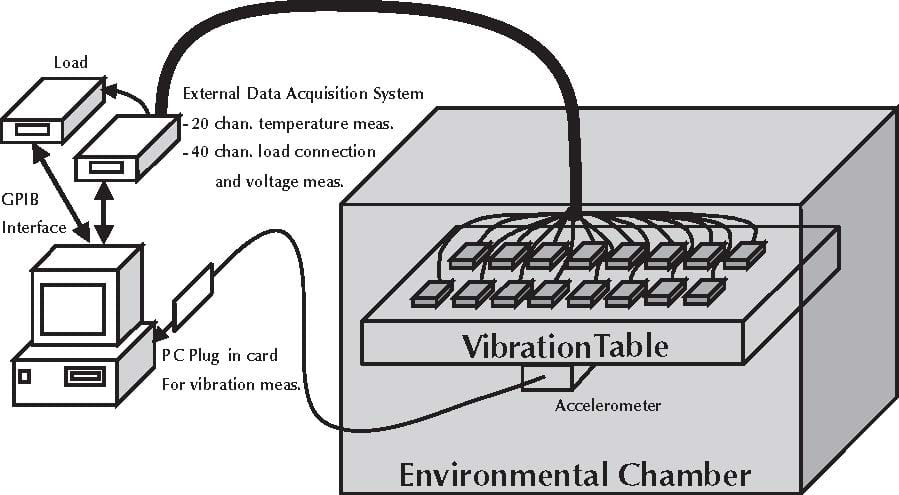

HALT and HASS testing are conducted in environmental chambers where high or low temperature, vibration, and other stress conditions are applied to the DUTs. In many cases, additional stresses not associated with the chamber may also be applied. These might include full power (burn-in) conditions and over-voltage conditions. To facilitate multiple DUTs, signal I/O and the application of power, test fixtures usually are employed inside the chamber.

Figure 2 is a block diagram of a typical HALT/HASS test system.

Major considerations in the specification of this equipment include:

• Channel count (associated with lot size and number of signals to be measured)

• Electrical noise (which may be associated with the DUTs, externally coupled into cabling, or a fundamental limitation of measuring instruments)

• Signal levels (both applied and measured)

• Speed, bandwidth, and throughput of instruments and other pieces of equipment

• Chamber size (associated with lot size, DUT size, and fixturing)

• Fixturing (mechanical design, racks, and special signal considerations)

• Cabling and connectors (selected for applied signal levels, low noise characteristics, and quick connect/disconnect)

Figure 2. Typical HALT/HASS System With Temperature and Vibration Cycling

To accelerate testing as much as possible, HALT and HASS programs often test multiple DUTs with multiple test points using multiple source and measurement instruments connected through a switching matrix. The only way to do this efficiently is to use a highspeed switch matrix that will not degrade the measured signals.

For example, in many telecommunications applications, HALT and HASS are conducted on DUTs that require the routing of microwave signals. Therefore, bandwidth and VSWR along the switch matrix signal paths are very important specifications. With appropriate characteristics, the switch matrix can:

• Help increase throughput (switching provides concurrent multipath testing)

• Reduce test equipment purchase costs (test multiple DUTs with less equipment)

• Maximize use of expensive test and measurement equipment

• Improve consistency and reliability (automation reduces the number of uncontrollable variables, such as manual tasks by test station operators)

When a DC stimulus must be applied to the DUTs and their response measured, synchronization, and triggering are important issues associated with speed and accuracy. For example, parasitic capacitance in cables and connectors makes it necessary to allow for signal settling time before measurements are made; otherwise inaccuracies occur. A sourcemeasurement unit, or SMU, (also called a force-measure unit or a SourceMeter®) provides tightly coupled, precision voltage and current sourcing and measurement in a single instrument that makes dealing with these timing issues much easier. Some of these SMUs offer high-speed data handling that allows more than 2000 readings per second into an internal buffer memory, and outputs up to 250 source measure pass/fail readings per second (4 ms per reading) to a remote computer over an IEEE-488 bus. This allows accurate HASS measurements at speeds often difficult for separate instruments.

Some SMU manufacturers also provide a component handler interface and digital I/O that makes it easy to connect and control the instrument in automated HASS test equipment, which typically includes the switching system and electromechanical DUT fixture. Another feature that can be very useful in these instruments is a source memory list that allows the user to program a sequence of many different tests with conditional branching, different pass/fail criteria, and different speed/accuracy settings for each test. In computer-controlled testing, this eliminates the need to transmit these instructions over the external data bus, which slows down measurements and reduces throughput.

Putting It All Together

HALT and HASS testing often require a wide variety of sources, measuring instruments, switching systems, RF routers, computer plug-in cards, and other data acquisition needs. Each of these pieces of equipment must be selected for high reliability, accuracy, repeatability, measurement integrity, and ease of use. Furthermore, they must be tightly integrated in a system that meets all of the enterprise objectives: spotting problems in production, ensuring a high level of quality, identifying critical flaws in new product early in the design phase, and reducing time to market. The system designer and integrator also need to consider the amount of work required to develop test application software for the system, as this can be a major part of the time to market equation.

Keithley Instruments, Inc. has a highly experienced staff of application engineers that can help system designers and integrators select appropriate equipment and quickly get “Up and Running” for their Accelerated Stress Testing measurement and data acquisition needs.

References

Keithley Instruments Application Note #2260, Burn-in Testing Techniques for Switching Power Supplies. (Available as a free download from the Keithley website at www.keithley.com/ast)

GLOSSARY

This glossary lists common terms associated with a class of testing used in both product development and manufacturing to improve or maintain the reliability of finished products.

Accelerated life testing (ALT).

A test activity during product development in which prototypes are subjected to stress (temperature, vibration, etc.) at levels much higher than those anticipated in actual use, with the aim of causing failures that identify weak design elements. These failure-prone elements are redesigned and tests are continued at higher levels. This procedure is sometimes called the Test, Analyze And Fix (TAAF) cycle.Accelerated stress testing (AST).

A post-production test activity on a sampling (100% at first) of units. The intent is to precipitate hidden or latent failures caused by poor workmanship and to prevent flawed units from reaching the next higher level of assembly or the customer. Stress intensity is typically half that used in accelerated life testing.

Burn-in.

Continuously powering a product, often at constant elevated temperature, in order to accelerate the aging process.

Characterization.

Gathering information about the device under test and/or the test system with the aim of establishing appropriate test conditions and methods.

Design limit.

The operational limit of a product, beyond which it is not required to function properly.

Environment.

The aggregate of all external and internal conditions (such as temperature, humidity, radiation, magnetic and electric fields, shock, vibration, etc.) either natural, man-made or self-induced, that influences the form, function, and reliability of a product.

Environmental stress screening (ESS).

Post-production testing in which 100% of produced units are subjected to stresses more severe than anticipated in actual service. The object is to precipitate failures associated with latent defects, so that the failed unit does not proceed further in production or reach the customer.

Environmental testing.

Subjecting a sample of products to a simulation of anticipated storage, transport, and service environments (such as vibration, shock, temperature, altitude, humidity, etc.)

HALT.

Highly accelerated life testing. See accelerated life testing.

HASS.

Highly accelerated stress screening. See environmental stress screening.

Life cycle testing.

A test procedure applied to a small percentage of products, subjecting them to stresses similar to those found in actual service. Typically, the goal is to determine the products’ mean time between failures (MTBF).

Mean-Time-Between-Failure (MTBF).

A basic measure of reliability for repairable items. This measure is the mean number of life units (hour, years, etc.) during which all parts of the item perform within their specified limits, over a particular measurement interval, under stated conditions.

Mean-Time-To-Failure (MTTF).

A basic measure of reliability for non-repairable items. It

is the total number of life units of an item population divided by the total number of failures within that population, over a particular measurement interval, under stated conditions.

Reliability.

The probability that a product will perform its intended function for a specified interval under stated conditions (such as cycling in a specified manner over a certain range of temperatures and vibration spectra). This probability is determined experimentally with repeated tests.

Shock (or shock pulse).

A transmission of kinetic energy to a device under test (DUT) in a relatively short interval compared with the DUT’s natural frequency period. A natural decay of oscillatory motion in the DUT follows. Sometimes this is done as part of a product’s environmental stress screening.

Thermal cycling.

Subjecting a product to pre-determined temperature changes, between hot and cold extremes.

Vibration.

Mechanical oscillation or motion about a reference point of equilibrium.

Specifications are subject to change without notice.

All Keithley trademarks and trade names are the property of Keithley Instruments, Inc. All other trademarks and trade names are the property of their respective companies.

© Copyright 2020 Keithley Instruments, Inc.

|

Keithley Instruments, Inc. |

28775 Aurora Road • Cleveland, Ohio 44139 • 440-248-0400 • Fax: 440-248-6168 1-888-KEITHLEY (534-8453) www.keithley.com |

|

No. 2280 |

|

|

Printed in the U.S.A. |

11003KDCI |