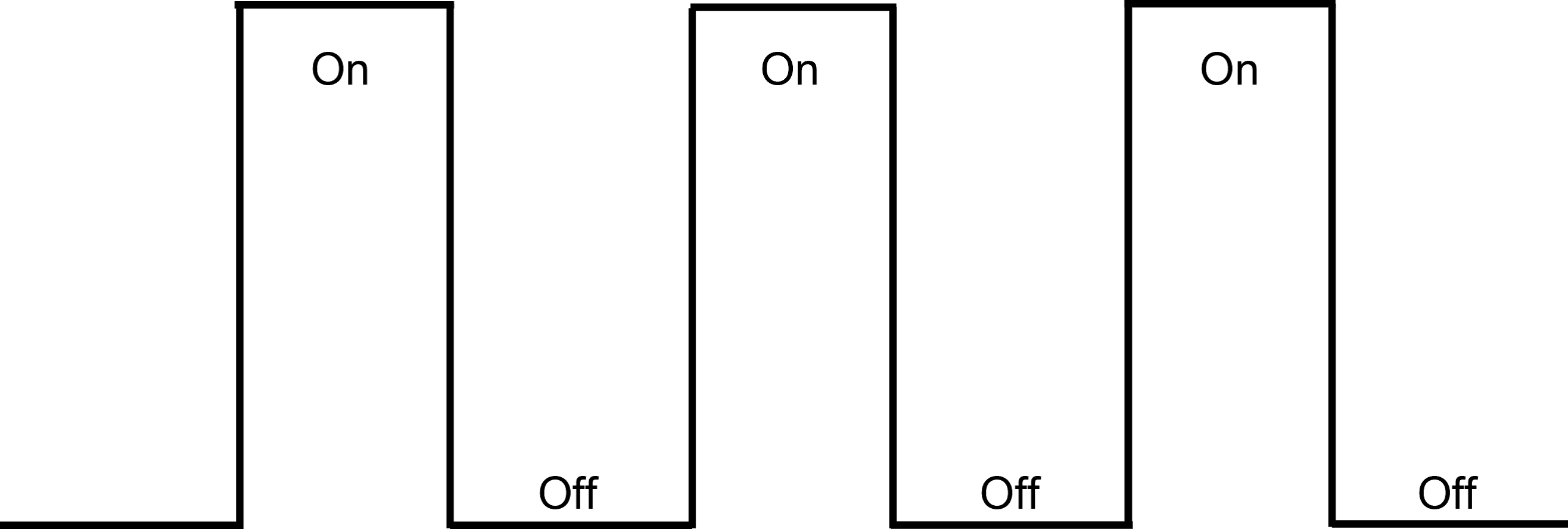

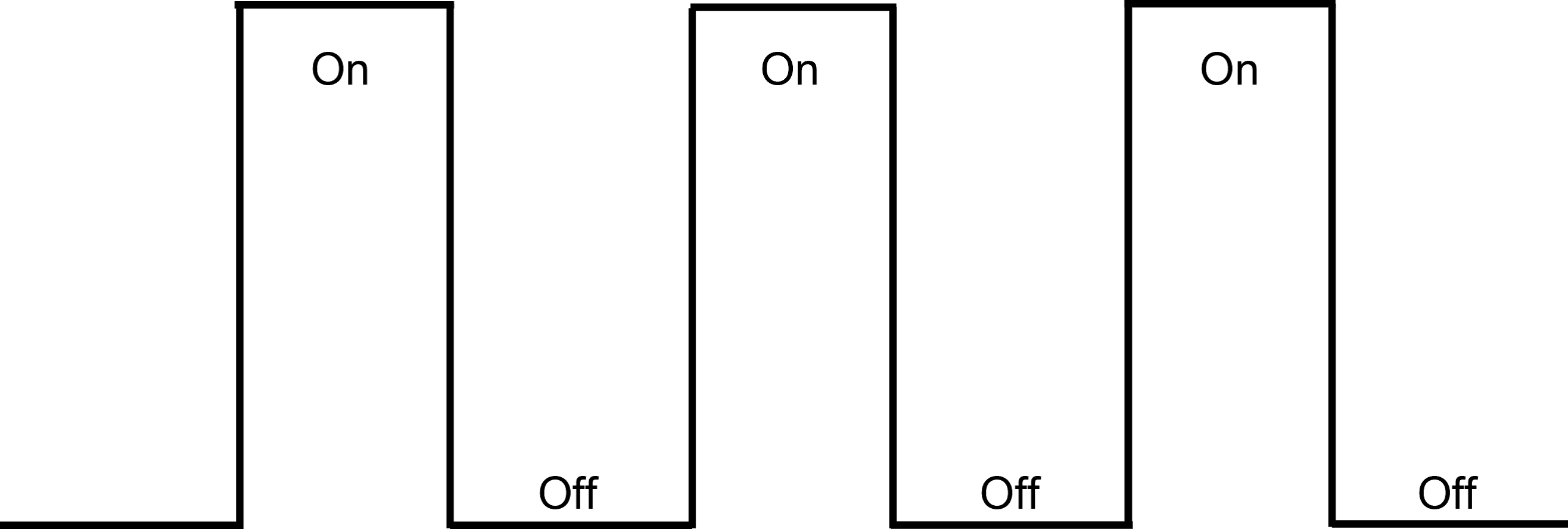

What is pulsing and why would I want to use it in my application? What can happen if I don’t pulse my high power semiconductor devices? As seen in Figure 1, pulsed signals are created by turning a voltage or current source’s output on for a specified amount of time and then off for a specified amount of time. It seems like such a simple concept, but is a very important technique in high power semiconductor testing because modern high power semiconductors are continuing to shrink in size compared to their ancestors. As they shrink, their power densities increase and their ability to dissipate heat without proper heatsinking decreases. This effect is called self-heating. Pulsed testing allows you to test these devices at very high power levels without overheating them because they have time to cool down during the off time.

Figure 1. Simplified pulse diagram

When should I use pulse testing?

Any high power, high voltage or high current semiconductor device can likely benefit from pulse testing. The most common devices in these categories are MOSFETs, IGBTs, HBLEDs and thyristors. All of these devices are at risk of self-heating during testing.

A good case for pulsed testing is the analysis of high brightness LEDs (HBLEDs). The final devices or modules are typically packaged and mounted to robust heat sinks that can dissipate plenty of heat, but it is impractical for LED manufacturers to test their devices for the first time after they have been packaged. The LEDs have very poor thermal properties before packaging and will heat up during testing. As the junction heats, the forward voltage will drop or the LED leakage current will increase during the constant voltage test. These effects can impact the accuracy of the test or, more importantly, potentially damage the device under test.

When is pulse testing impractical?

It simply doesn’t make sense to use pulse testing for some applications. Lower power devices don’t have the tendency to heat up like HBLEDs do. It would be a waste of time and money for low power device designers to purchase instrumentation that can do high power pulse testing and design tests based around pulsing.

It can also become impractical for automated testing applications where throughput is a very high priority. Pulse testing takes longer than traditional DC testing because the off time between test points can take up a significant amount of time. Pulse testing still makes sense if you need to test a lot of different points at high power levels and your device needs time to cool down between test points. However, if you only have a few test points you may be able to use fast DC testing and finish the test before overheating becomes a problem.

What can happen if I don’t pulse my high power device?

I was able to use the Keithley 2461 Source Measure Unit instrument to demonstrate what happens when a DC I-V sweep and pulse I-V sweep are performed on the same device. Figure 2 shows the instrument’s front panel displaying a graph of the two I-V sweeps digitized at a sample rate of 100,000 samples per second. The green trace shows the pulse sweep and the blue trace shows the DC sweep. As the test current starts to get above 1A, the two curves begin to separate from each other because the DC sweep is heating up the device. If you had just run a DC sweep on this device, you would be convinced that the blue curve is the standard behavior of the device, but the green pulsed curve is much closer to the proper operation of the device.

Figure 2. Digitized results of a DC and pulsed I-V sweep on a high brightness LED.

On less robust devices, the effect can be even more pronounced. Figure 3 shows a graph, again presented on the instrument, of the two I-V sweeps with a traditional A/D measurement taken at each sweep point. The green trace shows the pulse sweep and the blue trace shows the DC sweep. You can see the same deviations between the two curves, but the blue DC sweep trace eventually collapses and the current slams down to zero before the sweep is complete. This happened because the device self-heated itself all the way to complete catastrophic failure.

Figure 3. Traditional A/D converter measurements showing the results of a DC and pulsed I-V sweep on a high brightness LED.

Conclusion

Pulse testing isn’t necessary for all applications, but it can help you reduce testing errors and device damage in many high power testing applications. The Keithley 2461 SourceMeter can source up to 10A, 100V pulses and simultaneously measure voltage and current waveforms with its dual 1MS/s digitizing A/D convertors. You can find more information on the Keithley 2461 on the Tektronix Source Measure Unit product page. You can also learn more about HBLED testing with the Keithley 2461 by downloading the application note, Pulse Testing High Brightness LEDs Accurately using the 2461 High Current SourceMeter® SMU Instrument